Modules and packages in the ComposicaD lineup allow filament winding for:

- pipes and tubes;

- tanks and vessels;

- any figure of revolution;

- pipe tees and elbows;

- spars; and

- other geometric shapes.

According to Seifert and Skinner & Associates, the software was designed from the ground up to be completely user friendly, making it quick for the part programmer to make parts. The software is focused at the part level, not at the individual layer level, where much of today’s existing software is focused.

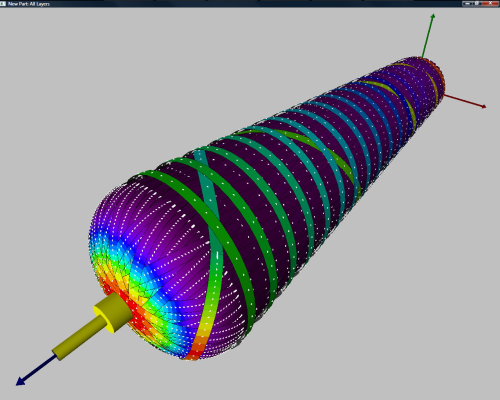

Many filament winders make a range of products – pipes or tanks that vary only in the overall length or diameter. Using ComposicaD, the part programmer builds the desired laminate table – the different layers of circumferential, helical and transition winding – and then can produce a range of parts, simply by varying the part length and/or diameter. ComposicaD automatically recalculates all of the layers to produce the new part. This can save an enormous amount of time, since each part doesn’t have to be laboriously programmed individually layer by layer.

ComposicaD software uses many improved algorithms for calculating the fibre paths and machine motions. It maintains a database of materials – commonly used fibre band setups – which include the band width, band thickness, maximum slip potential, band density, cost and other parameters. These parameters are used to calculate laminate weights, length of fibre consumed, and costs as well as the winding time, both on a total part basis and for the individual lamina.

The software produces machine output for up to six axes of motion – spindle, carriage, cross carriage, rotating eye, yaw axis and perpendicular axis. ComposicaD automatically calculates the thickness buildup and adjusts the winding contour. Winding speeds are controlled by the machine accelerations and velocities, including the fiber speed, and can be varied up to the limits, which are specific for the target winding machine.

ComposicaD produces output for all types of CNC filament winding machines and has capability to control other devices associated with the winding process, such as fibre tension, resin bath temperature, mandrel pressure, and other parameters.

Composicad is available exclusively through Seifert and Skinner & Associates and leading filament winding machine manufacturers. A demo version is available to qualified companies and individuals – see the Composicad website for details.

Seifert and Skinner & Associates says pricing for the software is competitive and competitive upgrade discounts are available for users of older filament winding software.