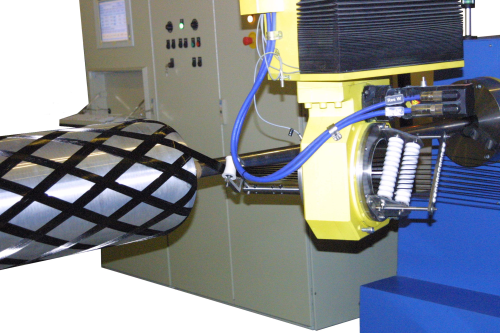

Filament winding is a very fast and efficient method of laying down resin and reinforcements to create strong, lightweight composite products. Windings are limited to the size of the machine and the rotating mandrel. Parts requiring mandrels of more than 30 m (100 ft) in diameter generally are wound at the site of the installation. Filament-wound parts provide high fibre volume fractions (up to 80%) and precisely controlled fibre orientation.

In the filament winding process, continuous strands of resin-impregnated glass fibre, carbon fibre or other reinforcements are wound under tension onto the mandrel in precise geometric patterns to build up the part. Once the desired winding thickness is achieved, the winder stops, the part is allowed to cure, and the mandrel is removed using an extractor. Mandrels can be left inside the winding to become an integral part of the component. Collapsible mandrels facilitate the job of extraction.

Most filament winders are two-axis machines. They have a carriage that moves back and forth along the mandrel, guiding the fibre rovings in either angled helical patterns for high tensile strength or in straight (90°) hoop patterns for enhanced crush strength. Chopped glass can also be sprayed onto the mandrel to selectively add material.

The rovings are fed from multiple spools positioned on a creel, through a tensioning system. A bath of catalysed low-viscosity thermoset resin is typically used to wet out the strands, although thermoplastic resin pre-impregnated tow preg materials can be used. For faster winding, dry fibres can be sprayed with resin as they are applied to the mandrel.

Multi-axis filament winding systems offer the ability to fabricate parts with up to six axes of motion control for the production of higher-performance pressure tanks and non-symmetrical components. Advances in winding software and computer numerical control enable the filament winding of such products as pipe elbows and other curved shapes.

Winding machine manufacturers

Competition is stiff among manufacturers of filament winding machines. Entec Composite Machines, a Zoltek company based in Salt Lake City, Utah, USA, claims to be the world’s oldest continually operating manufacturer of machinery for this process. Entec created the world’s first computer-controlled filament winding machine and developed the popular FiberGrafiX™ software for winding pattern generation.

Entec offers a complete line of machinery and equipment for filament winding, including four standard lines of machines. Entec machines range from the basic FW series in five sizes, the PW Series with an overhead beam design and up to two spindles, the PS Series of multiple spindle machines for high-volume production, and the rugged 5K Series for high-quality production with precise tolerances for aerospace applications, says the manufacturer. Entec can also provide multi-station turnkey production systems as well as retrofit options for existing machinery.

Among Entec’s largest machines is a 5-axis winder used to produce wind turbine blades measuring 54.5 m (180 ft) long and 8.23 m (27 ft) in diameter. Custom winders can be adapted to customer specifications, regardless of part length, diameter, weight, number of machine motion axes or number of spindles. Entec worked with carbon fibre supplier Zoltek to develop fibre management systems to enable large-tow 50K carbon fibres to work efficiently in its machines, replacing higher-priced 12K fibres for lower production costs.

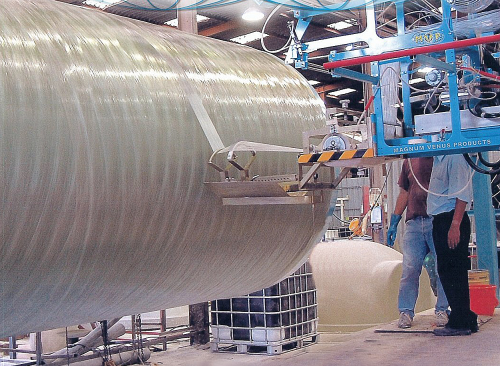

Another leading machine manufacturer, Magnum Venus Plastech (MVP), headquartered in Clearwater, Florida, USA, offers a wide range of Versa-Wind machines and equipment for the production of tanks and pipes. Winders range from the base-model Econo-Winder for hoop winding, to the versatile Ultra-Winder for helical winding, and the Multi-Axis Wind system, which can wind up to six axes at a time.

Rotating mandrel feature

Joe Jansen, MVP Advanced System Sales Engineer, tells Reinforced Plastics about an optional dual mandrel drive configuration that the company has offered for a number of years to enable nearly continuous operation of the filament winding process.

“With the dual drive, when winding is completed on one job, the carriage is rotated 180° so the operator can start winding on the second mandrel,” he explains. “Meanwhile, the first mandrel can be changed out with minimum downtime on the winder.”

The system eliminates the normal stop and start required to change mandrels and prepare for the next winding job.

A more recent MVP development is the End Bell Machine, designed to automate the process of manually applying chopped glass and resin to create tank-end domes and heads. The equipment enables a high degree of control over wall thickness and consistency of the part for improved part quality and reduced waste, relates Jansen. The machine can also monitor and record the amount of material being used for each part.

MVP manufactures and delivers large-scale filament winding systems used in the coal-burning power industry for on-site fabrication of behemoth scrubber tanks to remove sulphur dioxide from emissions. An MVP field winder was used to produce a scrubber vessel measuring 36.3 m (119 ft) in diameter and 18.3 m (60 ft) tall.

“Normally, a winder to produce a tank of that size is set up in the field at the power plant, and a temporary building is constructed around it,” explains Jansen.

“The tank might be made of 15 ft or 30 ft high sections, which are joined together to make the 60 ft height,” he notes.

In addition, concrete smoke stacks at these plants are typically lined with filament wound liners which measure 24.4 m (80 ft) or more in diameter.

“Once the fabricator completes the winding job, he moves the whole installation to the next power plant,” says Jansen.

The mandrels used to wind these large structures are dismantled and pulled out after the sections are cured.

A week or more is required to complete the winding of one of these large scrubber tank sections, which are about 2.5 inches (63.5 mm) thick when completed.

“You can only put on so much material in a given day before you have to stop winding and let it cure,” says Jansen. “You might wind half an inch of material, then stop, let it cure, then begin again the next day.

A winder for every job

Another leading manufacturer of filament winding machines is McClean Anderson, located in Schofield, Wisconsin, USA. Eight models of machines are offered – from the value-priced 2-axis Little Hornet, to the Cyclone, a workhorse for multi-axis (up to 6 axes) production winding. The range also includes the Gantry Motion Platform, featuring all digital AC servo technology.

These machines are driven by the company’s Windows®-based Flexwind machine control and Composite Designer winding pattern software.

McClean Anderson also offers a Tank Winder, specifically designed for production pipe and tank winding. Driven by the Patternmaster II machine control, the winder can accommodate a wide range of mandrel sizes. It features quick setup tooling and tailstock support systems. Also designed for production and tank winding is the Sand Delivery Winder, which doses sand as a filler to reduce production costs.

Macedonia is the home of Mikrosam, which offers a complete range of filament winders, from 2-axis to multi-axis and multi-spindle speciality machines and equipment. A laboratory series machine, model MAW20 LS, is specifically designed for advanced R&D, prototyping and small-batch production. It features an AC servo drive system, precision tensioning and a temperature-controlled resin bath. Another model, the MAW20 HC, offers heavy-duty construction and long mandrel capability. The multi-axis MAW20 MA machine is the most advanced in the range, providing up to 6 axes of motion control, interpolated for winding complex and non-axial symmetrical shapes.

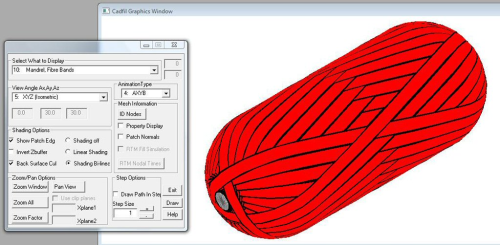

In France, MF Tech has developed a novel robot winding machine, which integrates a 6-axis Kuka robot for a total of 8 axes of motion control. The company has targeted applications in the aerospace and power industries. Using Cadwind filament winding software from Belgium developer MATERIAL, the robotic winding machine is capable of producing complex parts, such as elbows, tees and high-pressure vessels.

Netherlands-based Autonational specialises in turnkey, continuous and discontinuous winding machines for the production of composite pipes. The company can supply all the modules needed to wind pipe, couplings, tees and elbows, as well as equipment to handle everything from incoming raw materials through finishing, testing and shipping. A newly developed mandrel transportation system can increase the life of mandrels and reduce downtime.

A complete startup package for pipe and tank filament winding is offered by Dura-Wound, based near Portland, Oregon, USA. The package includes rugged, heavy-duty machines and a proprietary software program for generating setup parameters. Four models of filament winders are available. The company also supplies mandrels for pipe, duct and tank production; fibre delivery systems; tensioners and other equipment. Facility layout and setup support as well as technical training are also provided by Dura-Wound.

German manufacturer Waltritsch & Wachter GmbH (W&W) offers standard filament winding machines with up to 6 axes of motion control for products with a maximum diameter of 2.2 m (7.2 ft) and a maximum length of 12 m (39.4 ft). Custom sizes are also available. Both floor-mounted beds and gantry versions with overhead beds can be ordered. The company, located in Bodnegg-Rotheidlen, also offers conversion and retrofit of older BAER filament winding machines.

Bolenz & Schäfer (BSD) filament winding machines are available from EHA Spezialmaschinenbau GmbH in Steffenberg, Germany. EHA designs complete production cells to meet specific production needs. Various models of BSD winders are available, including the compact Type 2 laboratory machine and the Type 5 with a large carriage platform for winding diameters of more than 2 m (6.6 ft) and lengths of more than 9 m (29.5 ft). On this machine, the entire material supply, including resin, moves together with the delivery head.

Winding and pultrusion

Pultrex Ltd, based in Manningtree, Essex, in the UK, manufactures machines for filament winding, pultrusion and pullwinding, which is a combination of pultrusion and filament winding. The company’s pullwinding machines are free-standing and height-adjustable so that they can be interfaced to any standard pultruder. The combination of the two processes is well suited for high-volume production of extremely stiff, thin-wall tubes. Pultrex pullwinders are available with single or twin winding heads and feature independent, closed-loop microprocessor controls. An integral resin/fibre impregnation system is included as standard.

Styrene-free polyurethane resins formulated for filament winding applications are available from TSE Industries in Clearwater, Florida, USA. TSE-EcoWind® resins have been used to produce composite pressure vessels, tanks and pipe by filament winding. The product can be applied to reinforce thermoplastic substrates or applied directly to a release-coated mandrel surface. Advantages over polyester and epoxy resins with BPA include ultra-low emissions for a cleaner, safer work environment with a resin that provides similar tensile and flexural strengths, says TSE. The company has developed a patent-pending, dripless impregnator roller applicator for the resins.

|

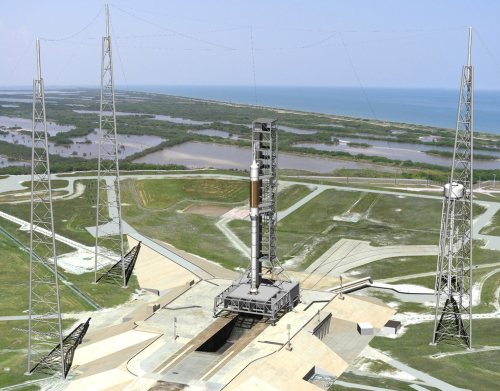

Ershigs Inc, a Bellingham, Washington, USA, fabricator of large-scale FRP tanks, vessels and structures, was recognised at the American Composites Manufacturers Association (ACMA)’s Composites & Polycon 2009 show for a filament-winding project it completed for the Kennedy Space Center in Florida. Nominated in the ACE Awards programme for Composites Excellence, the project consisted of fabricating three freestanding lightning protection masts, each measuring 2.1 m (7 ft) in diameter and 31.7 m (104 ft) tall. About 22.7 tonnes (50 000 lbs) of laminate was used for each, reports Steve Hettick, VP Manufacturing. Designed to protect a NASA rocket launch pad from lightning strikes, the composite masts were installed atop steel towers in February 2009. Cables connect the three structures, which stand at a height of 181 m (594 ft). A super-sized crane, rented at a cost of US$30 000 per day, was used to mount the masts, notes Hettick. Ershigs’ on-time deliveries kept that cost to a minimum for the Florida installer, Ivey’s Construction. The masts were principally fabricated via filament winding, with numerous ancillary components fabricated and installed using contact moulding and infusion methods, relates Hettick. The masts, which each took about 12 000 man-hours to complete, are reinforced with stainless steel support rings and are expected to withstand hurricane-force winds. They required extensive uniaxial reinforcement in addition to the helical filament winding, notes the fabricator. Materials included Ashland Hetron 992SB (Class 1 fire retardant vinyl ester) resin and Owens Corning Advantex winding strand and weft-uni products. |

Innovative filament winding

A wide range of composite products are made on filament winding equipment.

|

Computer software packages for filament winding pattern generation and optimisation enable fabricators to precisely tailor composite parts to meet specific requirements. Several companies produce this software, including Entec Composite Machines in the USA (FibergrafiX™), Crescent Consultants in the UK (Cadfil®), and the Belgian company Material (Cadwind®). Entec claims that its FibergrafiX™ software is used on more filament winding machines around the world than any other similar application. It creates fibre paths and the machine motions needed to wind parts for machines having 2 to 6 axes of motion. Pattern optimisation provides accurate fibre placement at high winding speeds. A finite element interface is available to simplify the task of creating FEA models. Three FibergrafiX packages are offered:

Patterns generated by FibergrafiX can be output to any filament winding machine’s computer control system. Crescent Consultants offers Cadfil in both standard and custom software packages for use with any numerically controlled winding machine. Cadfil-Lite offers many of the features of the more powerful Cadfil-Axsym package, with quick and simple parametric programming for the more common filament winding geometries. The Axsym version can generate winding programs for all rotationally symmetric components. Also available from Crescent is the Cadfil Spar Winding program, part of the non-axisymmetric suite of programs for complex winding geometries. Cadwind software from Material can calculate the winding pattern for any mandrel geometry and automatically generate the program to produce the part on any winding machine. Cadwind 2007 introduced new features and improvements, including a new graphics engine and redesigned graphics package, a machine simulator that shows an animation of the winding machine producing the part, and a simplified package and price structure with four packages. The Design Pack option includes a complete copy of Composite Star® database and design software. |

Cylindrical composite instrument housings for underwater applications and pressure vessels are manufactured by WindTec Winding Technologies AS in Hareid, Norway, a specialist in high-performance filament winding. Transponder tubes have been tested to a depth of 7000 m (4.35 miles). The company also produces buoys and equipment cans for marine research. The filament-wound products are coated for reduced wear and resistance to impact and corrosion.

Lightweight linerless composite air tanks are being commercialised by Composite Technology Development (CTD) in Lafayette, Colorado, USA, for a variety of applications. Among them is an air tank application for firefighter breathing apparatus. The tanks are 10% lighter and 10% smaller than comparable equipment. The carbon fibre reinforced tanks are made with proprietary KIBOKO® materials, which are based on a family of toughened epoxy resins said to provide superior resistance to microcracking.

The increased toughness also enables the production of linerless pressure vessels for aerospace and space applications. CTD-designed tanks were qualified for flight on the US Air Force FASTRAC nano-satellite. They weigh 40% less and have 18% more volume than the custom-built aluminium tanks they replaced – and 12 times the pressure capacity, says CTD.

Composite cases for GEM-40 rocket boosters are filament wound using graphite epoxy materials in an automated filament winding process developed by ATK Alliant Techsystems in Minneapolis, Minnesota, USA. The booster system, with a diameter of 1016 mm (40 in), was developed to increase the payload of Delta II rockets. Nine ATK GEM-40 solid-propulsion strap-on boosters provide augmented thrust during launch, before they are jettisoned.

The first fully composite liquified petroleum gas (LPG) tank was developed by Advanced Lightweight Engineering (ALE) in the Netherlands. These pressure vessels, typically fabricated of steel, are manufactured using a proprietary high-speed dry filament winding process. Designed for automotive use, the loW8 tank is 80% lighter than its steel equivalent and is designed to fit in the spare wheel compartment of a vehicle for LPG vehicle conversions. A rubber coating is applied to the tank to protect the fibres from sharp objects. Testing has shown that the loW8 tank will not explode in a fire, making it safer than a steel tank, reports ALE.

Filament-wound carbon fibre shafts for surf and rowing scull oars are manufactured using an automated filament winding process by CST Composites in Sydney, Australia. The shafts are said to be 10% stiffer and 10% lighter than traditional shafts made with fabric-wrapped prepreg materials. Wound using a high-temperature epoxy resin combined with aerospace-grade carbon fibres, the shafts have precise fibre orientations, high fibre-to-resin ratios, and excellent consistency, relates CST. The company also manufactures masts, spars and other components for the marine market as well as parts for industrial and high-tech applications. CST is the largest user of carbon tow in Australia and New Zealand.