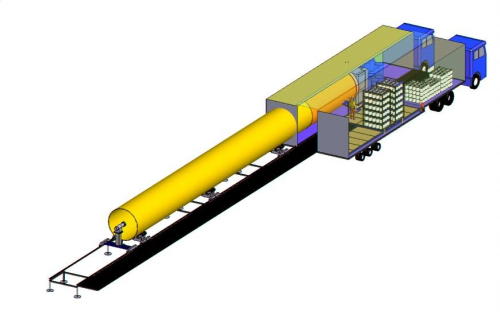

In this concept the 'factory' is transported to its production site, where the pipeline/filament wound product is needed.

There are two horizontal machines:

- a standard one for a mandrel of 2.4 m (8 ft);

- and one with a 6 m (20 ft) collapsible mandrel.

Length is unlimited, however a practical length is 30,000 mm (100 ft).

The vertical machine has a winding diameter of up to 10 m.

Installation time is short, says Rip-pro, at typically less than one working shift. The first trailer carries the machine and a second trailer the materials (resins, hardeners and additives). In addition, there is a small laboratory, an energy supply and all necessary auxiliary equipment.

The filament winding machine typically has a capacity of 1000-1500 kg laminate in one hour. However it can be up to 4000 kg per hour.