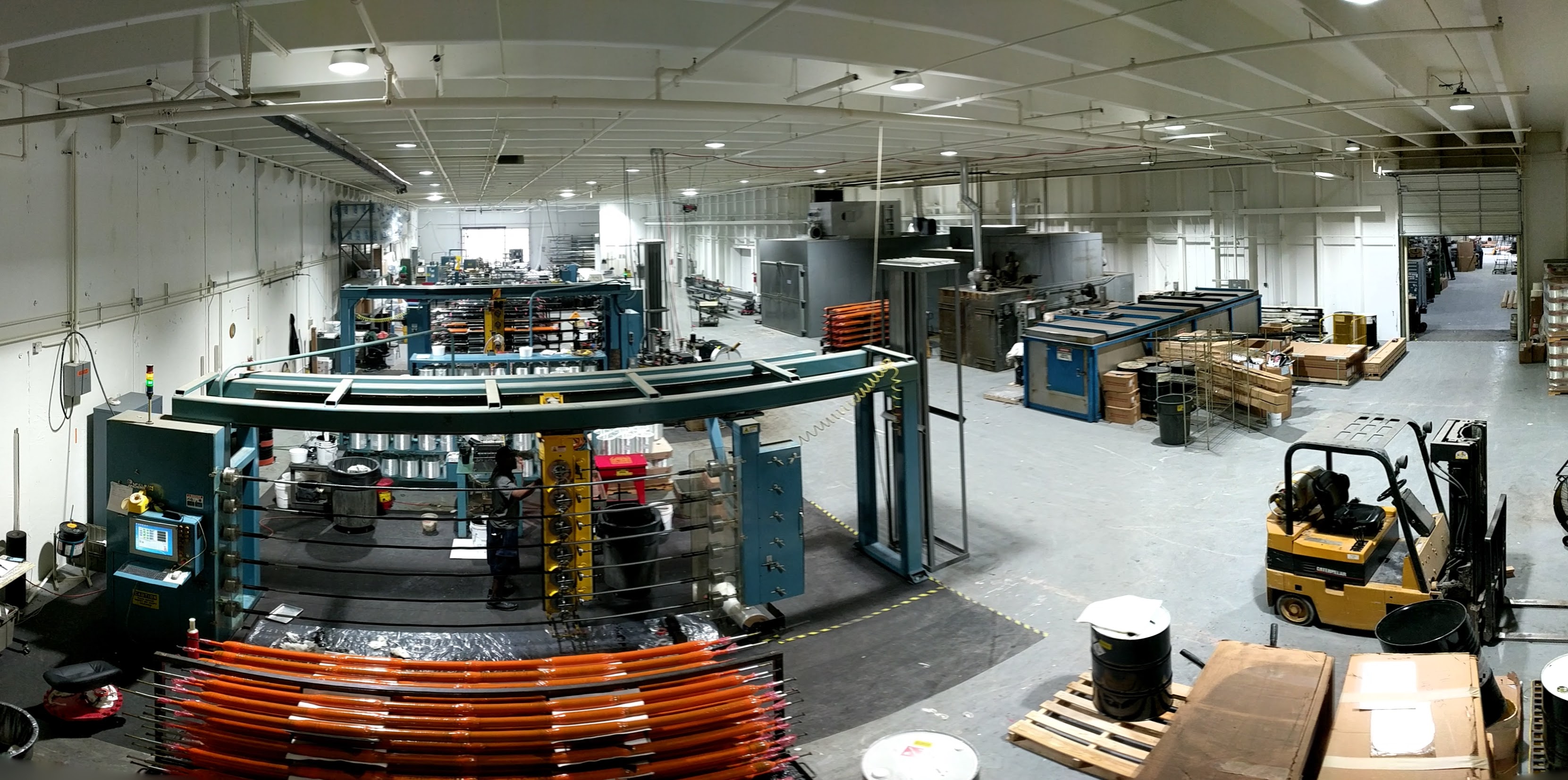

Rock West Composites (RWC) has opened a new, dedicated filament winding facility and expanded into a third manufacturing bay adding 20,000 ft2 of space for staff and new equipment.

The company has also aligned several multi-spindle, wet winding and tow preg, and small-to-large diameter winders suitable for manufacturing tubes in a variety of dimensions up to 315" long and 30" in diameter. RWC says that it has also installed a custom resin mixing and dispensing system and several ovens to accommodate the increased tube production, a new extended length hydraulic mandrel extractor, and mandrel storage. ‘RWC has extensive experience working with carbon fiber and glass fiber materials,’ said Dave Erickson, the general manager of Rock West Composites' Utah operation. ‘The expansion of our filament winding operation is a natural extension of the work we have been engaged in for years.’

This story uses material from Rock West, with editorial changes made by Materials Today. The views expressed in this article do not necessarily represent those of Elsevier.