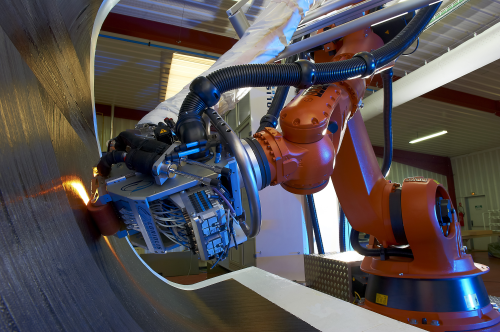

To see an automated fibre placement (AFP) system at work, its super-articulating head following an item's complex contour at miraculous speed, is to wonder how such items could ever have been laid up by hand.

Even were manual laminators able to lay plies on complex curvatures with the required fibre orientations and integrity, they would not be able to do so repeatably in series production. Nor would manual fabrication methods support the production rates now needed by the manufacturers of aircraft, ground vehicles and other items for which composites are now mainstream. Aircraft maker Boeing, for example, plans a production rate for its carbon composite B787 widebody twinjet of 38 per month within a few years.

AFP is one of the automated production technologies that will make this and similar manufacturing feats possible. Along with automated tape laying (ATL) and filament winding, it will be key to high-volume production of composite items, promising reliable, consistent and cost-effective fabrication.

Automated fibre placement

AFP has much in common with ATL but, while the latter is best suited to plain, relatively flat surfaces, AFP can be used with much more complex geometries. This is because it lays narrow tows, which can be steered over sharply curved surfaces whereas wider tapes cannot be so placed without buckling some of the fibres and potentially weakening the laminate.

When used with a rotating tool or mandrel, AFP more closely resembles filament winding, though use of tows tends to make it a faster process.

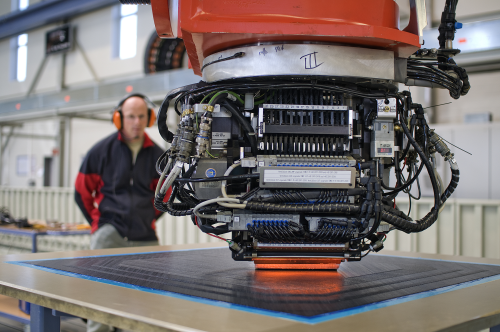

In AFP, a number of prepreg tows or narrow slit tapes are fed to placement heads that lay them down to form a continuous prepreg layer. Advanced machines can lay as many as 32 tows simultaneously, the tows being fed from creels located at or near the head.

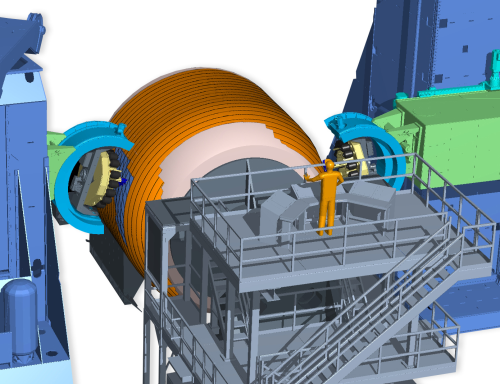

An AFP head can be mounted on a multi-axis articulating arm that moves around the tool/mandrel, or can be carried by a gantry. Alternatively, the tool can be rotated under a static head or both the head and the mandrel can move in a 'dance' choreographed by a software program.

As with most automation, AFP requires substantial up-front investment, but it has shown its ability to cover its cost in terms of saved labour and reduced material scrappage alone, not to mention its ability to lay tows accurately, reliably and repeatably to form laminates of exceptional quality.

Tows can be laid in any pre-programmed orientations and positions so that laminate can be tailored to deliver the strength and stiffness parameters required by the designers at various parts of the structure, fibres being aligned with the local forces expected in service. Material is laid free of tension and folds, with precisely defined pressure. Heads can carry out all necessary cutting and re-start operations plus consolidation with compaction rollers.

Carrying out multiple synchronous functions at speed requires accurate machine programming to ensure close coordination of cutting, motion and position control with highly dynamic reversal movements. Control of AFP has much in common with the computer numerical control (CNC) of machine tools, so it is no surprise that some of the heavyweight suppliers of AFP systems are companies rooted in CNC machine tools –- such as MAG (formerly Cincinnati Machine), Ingersoll and MTorres.

The use of AFP

CNC-controlled fibre placement machines first became commercially available in the late 1980s. By the mid-'90s, AFP production was becoming established, albeit on a limited scale.

A significant milestone was the production by a European consortium of a 4.5 m long carbon composite fuselage section under the Full-Barrel Composite Fuselage (FUBA-COMP) research project. This one piece section, up to 2 m wide, was produced at BAE Systems in the UK using a MAG VIPER 1200 CNC fibre placement system. This is one of three AFP families produced by this company, the others being the Viper 4000 and 6000 series.

Aircraft fuselages, with their pronounced and complex curvatures, are a major challenge for automation, but the VIPER, with its seven axes of motion, successfully placed carbon prepreg slit tapes for the honecomb cored structure, achieving a near-net configuration complete with all the necessary cut-outs and variable thicknesses. Appropriate software programming ensured that material wastage and removal operations were minimised.

Similar automation has subsequently been applied by Hawker Beechcraft to the production of carbon/epoxy composite fuselages for its Premier 1 and Hawker 4000 business jets. Multiple VIPERS at the company's Wichita, Kansas, manufacturing facility combine programmable 7-axis dexterity with start/stop/cut control over 24 individual one-eighth inch wide fibre tows. The machines are 90 ft long and can accommodate long fuselage mandrels for the larger, Horizon jet.

Hawker claims that AFP enables complete fuselages to be made in a fraction of the time required for equivalent metal structures. This, together with vastly reduced part count, simplified assembly, reduced maintenance and the better performance of the final product, makes the technology a clear winner in the company's view.

Boeing has followed suit and is using VIPER 6000s for the barrel sections of its B787 fuselage.

A Viper AFP system sold last year to Russia's United Aircraft Corporation is believed to be the first automated composites processing system sold into Russia. The equipment will support production of UAC's MS-21 series of medium-range airliners.

On the military aviation front, in 1998 Alliant Techsystems (ATK) demonstrated the ability of AFP to manufacture a composite air inlet duct for the Lockheed Martin F-22 Raptor fighter. ATK had by then established a track record in AFP manufacture including certain other parts for the F-22, the work taking place in a dedicated fibre placement production facility in Virginia.

Since then, ATK has used AFP to produce 35 ft long composite skins for the upper wing surfaces of the F-35 Lightning II joint strike fighter (JSF), bringing unprecedented precision to the manufacturing process. Tows for the skins are laid down on a large mandrel fashioned in heavy invar metal for thermal stability and durability.

Recently ATK ordered two more MAG Viper AFP systems for F-35 production, adding to five VIPERS it already has at North American sites. The new machines, due for delivery early next year to ATK's facility in Clearfield, Utah, will have MAG's ACES software (Advanced Composites Environment Suite), a modular programming and simulation system that will be extended with features to aid programming of existing machines at the plant.

MAG is said to have won the contract on cost, its ability to optimise the product for the client's particular application, and the high lay-up rates achievable with difficult bismaleimide (BMI) material – important, apparently, in meeting cost reduction targets for the F-35 programme.

VIPER attributes include independent control over feed, clamp, cut and re-start for up to 32 individual tows, automated 'on the fly' adjustment of fibre band widths and controlled placement of fibres over sharply changing contours and around openings. The system allows wrinkle-free, near net-shape lay-up of enclosed and deeply contoured structures for the precision manufacture of fuselage sections, panels, cowls, ducts and nozzle cones for a range of aerospace assets. The Viper 6000 handles tow widths of 3.2, 6.4 and 12.7 mm.

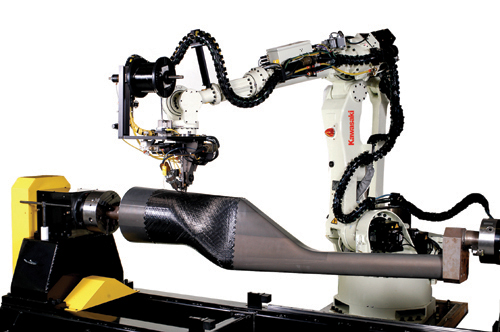

Spanish concern MTorres is another machine tool specialist to have developed AFP and ATL equipment. An early AFP system from the company went to Japan where Kawasaki Heavy Industries is using it to produce monolithic fuselage sections for Boeing's B787 programme. This system can lay up to 24 half-inch tows simultaneously. By contrast, similar machines used by GKN Aerospace and Spirit AeroSystems to produce wing spars steer 16 quarter-inch tows round the spars, including their sharply curved edges. Dealing with those edges requires careful attention to the setting up of the TORRESFIBERLAYUP machines, with fine tuning of multiple parameters.

A spokesman for MTorres noted that its machines must be able to run a wide range of materials, some of which are challenging. For instance, the Toray Torayca 3900 series epoxy prepreg used for most B787 components and the Hexcel Hexply M21 material chosen by Airbus for A350 parts both have low resin viscosity – this offering the best structural properties after curing. These materials therefore require higher temperatures and pressures at the point of compaction than the average.

Tows and prepreg

The simultaneous laying of multiple tows by fibre placement is widely seen as the supreme composite automation discipline. According to Automated Dynamics, a New York-based company that produces advanced composite structures as well as production automation, AFP tows some 3 mm to 6 mm thick are used to conquer 'difficult' geometry challenges while tapes of double this width may serve on less severe curvatures, thus improving throughput. Thermoplastic tapes as wide as 50 mm can be laid singly in operations still referred to as AFP because the tapes are considered to be narrower than those traditionally used for tape laying. Tow/tape can be placed in any axial orientation between 0 and 90 degrees, allowing stiffness and strength to be optimised within a low weight and at an affordable cost.

Automated Dynamics says its head technology enables it to offer the advantage of in-situ consolidation, each precision placement head being associated with an elastomeric compaction roller that may be heated or cooled for consolidation purposes. In-situ consolidation is said to result in structures having low void content, a superior finish, good fibre concentricity and minimal buckling.

The drape and high tack of most thermosetting resins under normal ambient conditions raises difficulties for automatic handling, including unwanted resin migration. This is mitigated partly by using prepreg materials having reduced drape and tack and partly by providing a cooled feed environment so that resin migration and build-up are avoided. The prepreg resin can be softened prior to consolidation by using an infrared (IR) lamp to apply heat to the nip point of the compaction roller. Surfaces in the feed system that have high contact with prepreg, such as rollers and guide chutes, are specially coated to combat resin 'stiction'. Tape guidance systems maintain close geometric tolerances relative to the prepreg cross section so as to prevent buckling during the feed sequence.

Thermoplastic prepreg is easier to handle than thermoset. Because resin transfer is not the issue it can be with thermosets, an enclosed feed chamber with active cooling is not needed. However, component wear may be substantial so hard surface finishes are provided on contact parts. Compaction roller heating is applied, in the same way as with thermoset prepreg, to reduce resin matrix viscosity at the feed point.

Coriolis Composites in France was originally founded by three competition sailors who sought affordable series production of boats. Nowadays, major clients are in commercial aerospace, wind turbine and automotive sectors as well as performance yachting. Coriolis' innovative system, developed over ten years, utilises a standard off-the-shelf poly-articulating robot arm as the basis for a fibre placement system having eight axes of motion. Use of standard robotic components makes the system flexible and economically attractive, says the company.

Coriolis is also proud of its AFP system’s low head weight and hence low inertia which, together with powerful drive motors, make high lay-down rates possible. Hardware refinements include flexible pipes to protect and guide the fibres, and a creel-mounted tension reduction and equaliser system. CADfiber for Windows and Catia V5 CATfiber software is used for command programming and composite design optimisation. The two-module stand-alone package helps users optimise the laminate design and the placement of fibres on a range of curves, both geodesic and non-geodesic, as well as curve offsets. Control functions include tow steering, minimum fibre length check, roller compliance, fibre position on the roller, cut and restart for each tow, and automatic trim for contours.

System maturity coincided with the desire of aerospace and other fabricators to industrialise their composites production and this has taken Coriolis into the aerospace market. Significant airframer clients include Airbus and Bombardier Aerospace. Bombardier recently ordered AFP systems from the French company for manufacturing parts for its new C-Series, an extensively composite regional aircraft expected to enter the market in 2013.

A faster future

The future for AFP probably lies with machines that are considerably faster than those in use today. Increases in manufactured part size and complexity, together with the high rates at which the aerospace industry needs to fabricate those composite parts, have created the need for on-the-fly fibre placement at 2000 inches per minute and more, several times faster than current-generation machines can achieve. Such speeds are required to avoid the need for multiple slower machines working in parallel. While re-engineering of systems for feeding, cutting and machinery control has resulted in machines that can deliver rates of this order, progress continues and further refinement is likely to push speeds even higher.

Raising the speed bar to these levels places high demands on mechanical systems, servos, controls and programming systems. A realistic lay-down includes many short courses (a course is a single pass of the machine, which can be laying down multiple materials tows or tapes) over sharp contours, and bi-directional lay-down for speed. The machine will continually be accelerating and decelerating in multiple axes to maintain the surface parameters required. Within the feed system, spool dynamics are closely controlled with associated 'dancer' rollers and pneumatic disc brakes. High-speed computing is needed to maintain precision in positioning, cut placement and timing.

American company Electroimpact Inc, self-billed as a world leader in design and manufacture of aerospace tooling and automation, has developed AFP technology for laying tow at up to 2000 inches per minute over complex items, whilst allowing cutting and adding within customer-defined end placement tolerances. Its system can dispense multiple tows or slit films ranging from a quarter inch in high contour areas to two inches or wider over lower curvatures. All lay-ups can be performed bidirectionally and operators can control the feed rate without affecting end cut accuracy.

A particular challenge the company faced was that of on-the-fly cutting. Cutting a tape that is moving fast through the guide system requires careful timing of blade and shear edge arrivals so that a ragged cut – or worse, failure to sever – are avoided. Electroimpact developed a new guide chute system to secure this, as well as high-speed cutter actuation to avoid the blade exerting drag on the moving material. Accurately timed cuts are made in less than one millisecond. Extremely tight integration of the CNC motion control and the timing of cut and add commands is achieved.

Demand for high-precision software programming has led to another trend in AFP/ATL circles. There is growing reliance on specialist program developers as high placement speeds increasingly outrun the capability of control software engineered by AFP machine tool vendors. Rigorous programming can avoid the end placement errors sometimes seen with less effective programs.

Electroimpact, for one, has taken the specialist out-sourcing route, having contracted CGTech to develop a variant of its VERICUT suite specifically for its AFP system.

Also in demand is FiberSIM from VISTAGY Inc. This, and associated modules from the company's Aero Suite, are used by a number of aerospace contractors including Tier 1 suppliers like GKN Aerospace. Recently the SOLVER Company of Russia purchased Vistagy software for use with a Viper 1200 fibre placement system.

Electroimpact AFP machines are used, inter alia, by Spirit AeroSystems in Wichita, Kansas, to produce composite fuselage nose sections for the Boeing B787. SOLVER will use the VIPER/FiberSIM combination to design and manufacture composite parts for various projects being undertaken by the Voronezh Aircraft Plant (VASO).

In summary, AFP is progressively becoming a highly capable automation platform. Joining ATL and filament winding as the primary tools for laying down quality composite laminates, it has become a standard process for fabricating large complex carbon-epoxy skins and shells. As such, it is in the process of revolutionising the high-volume production of complex aerospace structures. ♦

This feature was published in the May/June 2011 issue of Reinforced Plastics magazine.

To apply to receive your free copy of each issue of Reinforced Plastics magazine please complete the registration form.