| ... we can deposit fabric at a rate 100 times faster than current processes; we’ve also reduced material costs by 50%. |

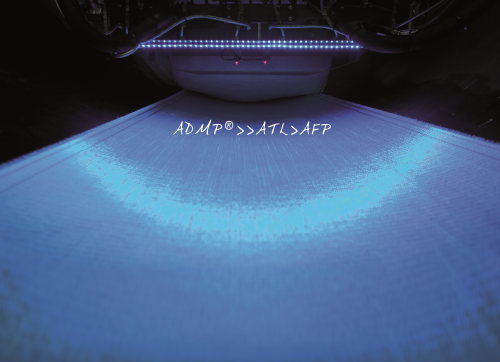

The ADMP can be used with fabrics, other textiles or unidirectional tapes. The machine places the cut fabric onto moulds with complex geometries. Composite parts, such as an aircraft wing skin or frames, can then be manufactured using a resin infusion process.

“Current manufacturing processes for prepreg are labour intensive and costly," explains Asier Gandarías Mintegi, CEO of DANOBAT Composites.

"Using dry material we can manufacture highly integrated composite structures while reducing assembly costs, and replacing manual steps with automation. As a result, we can deposit fabric at a rate 100 times faster than current processes; we’ve also reduced material costs by 50%."

Spanish company DANOBAT Composites creates turn-key manufacturing processes for industries such as aerospace, automotive, energy, and transportation. It is a division of the DANOBATGROUP, a manufacturer of specialised machine tools and production systems.