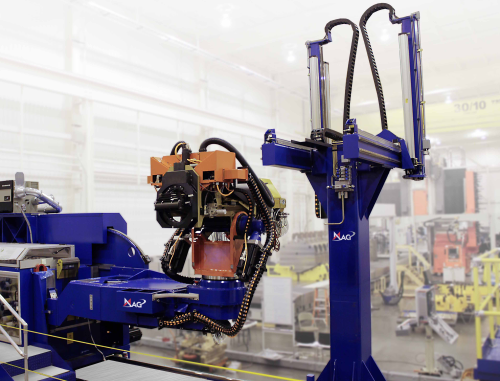

The new interchangeable cut/clamp/restart (CCR) module for fibre placement machines is said to increase a facility’s output without new machinery or infrastructure. Developed for Boeing South Carolina, the CCR changing system allows offline servicing of a contaminated end effector to increase the production availability of new or existing machines. Boeing purchased the option on a new VIPER® 6000 Automated Fiber Placement (AFP) System for its North Charleston, South Carolina, facility.

The VIPER AFP system is widely used for automated layup of complex composite aerostructures.

MAG estimates the CCR changing system will yield higher machine utilisation and a significant time savings on part production through minimised interruption of part layup.

“We expect the interchangeable cut/clamp/restart (CCR) system to be an important factor in helping Boeing fulfill its plans for increasing production rates at the South Carolina facility,” explains Robert Harper, Director Technical Sales, MAG Composites.

“The VIPER 6000s have delivered highly reliable layup for fuselage sections since 2006. The interchangeable CCR module will maximise the machines’ efficiency and throughput, particularly when fabricating these large parts.”

The CCR changing system automatically exchanges one end effector for a second that processes the same width material, utilising a docking stand outside the work zone. The offline CCR can then be cleaned or serviced without interruption to production. The interchangeable CCR module is designed for easy maintenance, and can be disassembled in minutes without hand tools.

“Unlike head docking, this system leaves all the raw material aboard the machine and changes the end effector only," Harper adds.

"This makes the exchange fast and simple."

The interchangeable CCR module also includes high-speed cut and add-on-the-fly rates as a standard feature.

Also see:

Automating aerospace composites production with fibre placement (feature article) As with most automation, advanced fibre placement (AFP) requires substantial investment, but it has shown its ability to cover its cost in terms of saved labour and reduced material scrap, combined with the ability to form laminates of exceptional quality with higher accuracy and repeatability.