Introducing the press conference, Nick Stanage, Chairman, Chief Executive Officer and President outlined the Hexcel Corporation of 2014. The company has been active in the composites market for 65 years and is now primarily focused on the aerospace and wind energy markets. Sales in 2013 were $1.68 billion, with 46% in the US, 39% in Europe and 15% elsewhere. The company has 5,300 employees, mainly split between the US and Europe. He highlighted the company’s main composite material areas of interest and applications. These included:

- Carbon fibre (A350 fuselage and wings; LEAP fan blades/case; F-35 wings

- Reinforcements (aircraft radomes; 787 fabric for stringers; BMW roof)

- Carbon prepregs (aero primary structures; A380 central wing box; GE90 fan blade; Eurofighter wings)

- Glass prepregs (wind blades; wing-to-body fairings in aero)

- Honeycombs (helicopter blades; aircraft flooring; nacelle structures; Acousti-Cap®)

- Engineered products (structural assemblies; HexMC® materials; Machined Core; HexTool® Tooilng System)

Commercial aerospace accounts for 65% of the company’s business, with space and defence at 22%. Industrial applications (wind energy, recreation and transportation) accounting for 13%. Hexcel reports strong global demand in the commercial aircraft sector. There is a backlog of more than 10,000 planes at Airbus and Boeing or around 8 years estimated at 2013 deliveries. Last year was a record year for deliveries and 2014 is expected to be so as well. Hexcel adds that the introduction of these composite intensive aircraft now means that it is supplying around $5 million worth of materials for the Airbus A350, for example. Thierry Merlot, VP and General Manager then summarised the A350XWB and LEP-1 programmes. With the maiden flight taking place in June last year, flight tests have been progressing well. At the end of January there were 814 orders from 39 companies. Hexcel’s content on the A350 includes: radome; passenger doors; nacelle structure; wing and horizontal stabiliser; fuselage; fuselage – Section 19/19.1; wing leading and trailing edges; ailerons; wing covers; and belly fairing. On CFM’s LEAP-1 engine, Hexcel has been awarded the long term contract by Safran to supply all the carbon fibre for the fan blades and containment cases. HexTow® IM7 fibre was selected for its high tensile strength and modulus, and good shear strength. Hexcel will also supply Safran with HexPly® carbon prepreg for the A320neo nacelles. Finally, Paul McKenzie, VP Research & Technology highlighted Hexcel’s new products, starting with HexTow® HM63.

HexTow® HM63

Hexcel has added to its range of IM and AS fibres by launching a new high modulus carbon fibre, called HexTow® HM63. This new fibre has the highest tensile strength of any high modulus fibre and provides good translation of fibre properties in a composite, including good interlaminar shear and compression shear strength. Hexcel adds that it is therefore ideal for any high stiffness and strength-critical applications including space, satellites, UAV, commercial aerospace and helicopters. It also meets the special requirements for premium sports and recreation applications including F1, marine craft, bikes and fishing rods. At JEC Hexcel displayed a ThermoSet Carbon (TSC) cable for yacht rigging manufactured by Future Fibres, using HexTow® HM63 high modulus carbon fibre for low weight, high break strength and resistance to impact.

HexPly® M92 prepreg

Designed for aerospace structures, HexPly® M92 prepreg is claimed to combine all the major benefits achieved individually with other 125°C curing epoxy resins in one new ‘multi-purpose’ system. These benefits include good hot wet Tg performance of 115°C, allowing HexPly® M92 to operate at higher service temperatures from a lower cost 125°C cure. The system is self-adhesive to honeycomb, making it suitable for sandwich structures as well as monolithic components. Other benefits include high toughness, fire resistance, low exotherm, a long out/tack life and the ability to cure by vacuum bag. HexPly® M92 is available in a wide range of prepreg forms (woven and UD tape). At the JEC show, Hexcel displayed a Helicopter Rotor Hub Cap Fairing manufactured by Airbus Helicopters. This oven-cured part is a honeycomb sandwich structure in which the prepreg is bonded directly to the non-metallic core, without any additional adhesive. Airbus Helicopters estimates that weight savings of 8-15% will be achieved by manufacturing this part from HexPly® M92, depending on the helicopter type.

HexPly® M77 ‘Snap Cure’ prepreg

To further extend the use of thermoset resins in mass produced composite parts Hexcel has developed HexPly® M77, a rapid curing epoxy prepreg that allows automotive components and sports goods to be press-cured in a 2-minute cycle at 150°C (80 bar pressure). Hexcel says that the low tack of HexPly® M77 enables the prepreg to be cut into precise shapes by laser cutter. The individual plies can then be oriented, assembled and consolidated into a flat preform by robot. Once in the mould HexPly® M77 has an optimised gel time that allows the resin to flow into the contours to produce the precise geometries required. The high Tg of 125°C enables the cured parts to be demoulded while hot for a faster production cycle. This rapid-curing product, with a 6-week outlife at room temperature, is available in various forms including unidirectional or woven reinforcements and heavy tow fibres. It is also supplied as HexMC®, Hexcel’s high performance carbon fibre/epoxy compound developed specifically for compression moulding processes. HexMC® is ideal for the series production of complex shaped parts with thickness variation, sharp angles or parts that require inserts to be integrated into the moulding process such as screw threads.

HexPly® M79 Low Temperature Cure prepreg

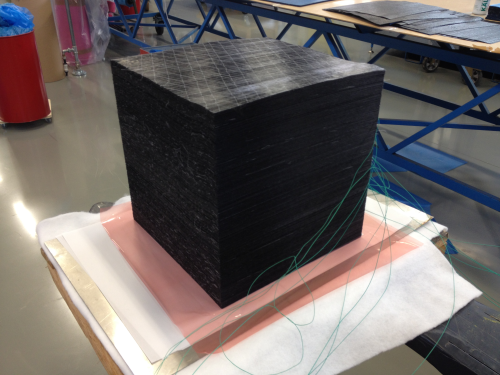

HexPly® M79 Low Temperature Cure prepreg has been developed for wind blades and marine applications. Hexcel says that HexPly® M79 was developed to meet industry requirements for a faster and lower temperature curing prepreg for thick laminates. It has evolved from HexPly® M10, Hexcel’s long-established and widely used prepreg resin for marine structures and wind blades. A number of cure cycle options are possible for HexPly® M79 including a very low temperature cure of 8-10 hours at 70°C or a more rapid cure cycle of just 4-6 hours at 80°C. With previous systems it could take 10 hours to cure a laminate at 80°C. HexPly® M79 also has a very long outlife at room temperature of at least 6 weeks. When HexPly® M79 carbon fibre UD prepreg is used in conjunction with Hexcel’s patented grid technology a void content in the cured laminate of less than 1% is achievable, regardless of the part thickness. Hexcel demonstrated at JEC what the company believed to be the thickest carbon prepreg laminate ever made. The lay-up of 695 plies of HexPly® M79 600 gsm carbon UD tape with Hexcel’s grid technology is 400mm thick – and it cured in just 6 hours at 80°C. The very low exotherm of HexPly® M79 allowed the temperature to be increased more quickly in the mould, resulting in a shorter cure cycle.

HiTape® Aircraft Fuselage Panel Demonstrator

HiTape® advanced dry carbon fibre reinforcements combine the benefits of automated processing with the cost-effectiveness of Out of Autoclave infusion technologies. HiTape® allows preforms to be manufactured in a fully automated lay-up process, with high deposition rates. Parts produced with HiTape® and Hexcel’s HexFlow® infusion resins can be up to 30mm thick with a 58-60% Fibre Volume Content, resulting in mechanical properties that are as high as those achieved with primary structure prepregs. To demonstrate the potential of HiTape® for cost and cycle efficient next generation aircraft primary structures, Hexcel has worked with Aerolia SAS and Coriolis Composites to design and manufacture an aircraft fuselage panel demonstrator that was on display at JEC. Aerolia SAS is a major world player in the design and production of aircraft equipped fuselages. Coriolis Composites is a leader in the development and manufacture of automated fibre placement processes for composites. The fuselage panel is a self-stiffened skin that was designed by Aerolia to meet the mechanical performance requirements for primary structures. Coriolis Composites developed the dry Automated Fibre Placement process for the full scale fuselage skin demonstrator - and the dry preforms were made at Compositadour’s facilities. The HiTape® preform skin and stiffeners were infused with HexFlow® RTM6 resin at Hexcel’s new Applications Laboratory in Les Avenieres, close to Lyon, using a co-infusion process that was developed in-house. The resulting fuselage panel demonstrates that parts made with HiTape® and HexFlow® RTM6 meet the high mechanical performance requirements for primary structures, including toughness. Hexcel adds that HiTape® is a cost-effective, highly automated solution for the manufacture of aircraft primary structures that enables aircraft designers to meet the cost and build rate targets for next generation aircraft, while retaining the weight-saving benefits that are achieved with prepregs.

This article was published in the May/June 2014 issue of Reinforced Plastics magazine.

The digital edition of Reinforced Plastics is distributed free of charge to readers who meet our qualifying criteria. You can apply to receive your free copy by completing this short registration form.