Sigma Engineering, which makes processing simulation software, has developed a new way for users of its software to share results interactively.

SIGMAinteract also makes it possible to share SIGMASOFT results in 3D with colleagues, project partners and customers, the company said.

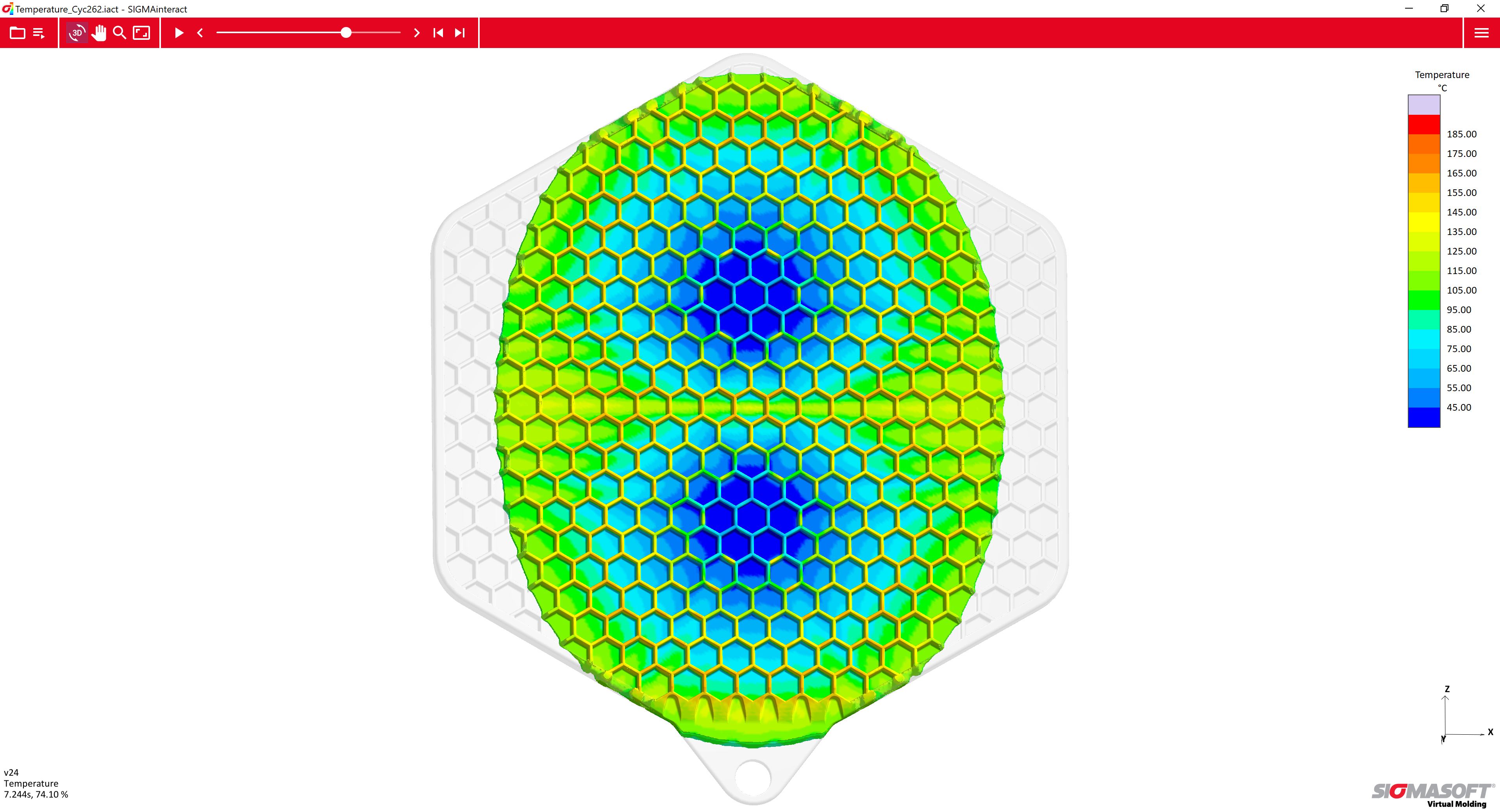

In one project part design and tool construction were done in parallel so it was necessary for all partners to work closely together. The software conducted virtual Design of Experiments (DoE) for the validation of the part design and the evaluation of the heating concept. Results showed that the honeycomb structure of the part placed high requirements on the material and the tool, Sigma said. There was also a high possibility for air entrapments at the weldlines of the comb walls and premature curing during filling which would need to be prevented. Using the software, the length and power of the heating cartridges could be better determined to achieve an even temperature distribution in the cavity area.

This story uses material from Sigma, with editorial changes made by Materials Today. The views expressed in this article do not necessarily represent those of Elsevier.