GOM, which makes systems for 3D digitizing, said that it has updated its GOM Correlate software to include new application-specific features.

This includes a software tool suitable for auto applications which can enable contour detection and the analysis of airbag deployment tests, GOM says. The tool can track the contour of the airbag in any high-speed video recording and helps to identify the maximum deflection point in the local coordinate system of the steering wheel.

Another new feature of crack tip detection makes the tracing and evaluation of the trajectory of crack points possible, according to the company. It can be used for a wide range of applications in materials research such as metals, plastics and composites and in many industries with high security requirements.

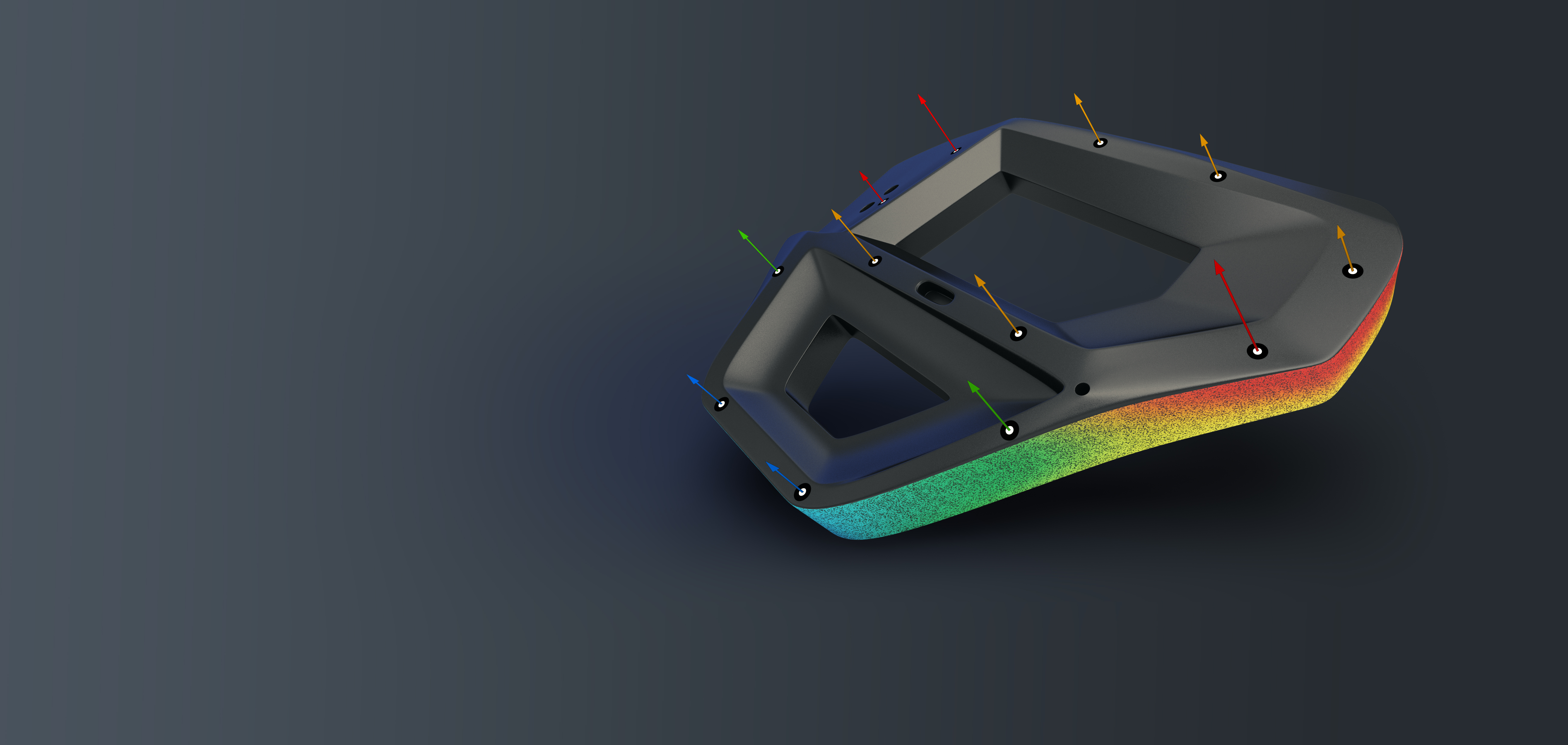

GOM says that measured data from typical materials testings, such as Nakajima, bulge, tensile, bending, shear and hole expansion tests, can be evaluated in the software to determine the material characteristics. This data can then be used as input parameters for the numerical simulation, enabling a more precise material model and a more accurate prediction of material behavior. In the new GOM Correlate Professional software, measured 3D data could be combined with imported temperature data from an infrared camera, so that the correlation of the thermal and mechanical component behavior can be obtained and analyzed.

This story uses material from GOM, with editorial changes made by Materials Today. The views expressed in this article do not necessarily represent those of Elsevier.