Sigma Engineering has developed a new version of its Sigmasoft software which covers the simulation of compression molding processes of rubber compounds.

Up to now, simulative design of mold and process has been mainly focusing on modern injection molding technology, the company said.

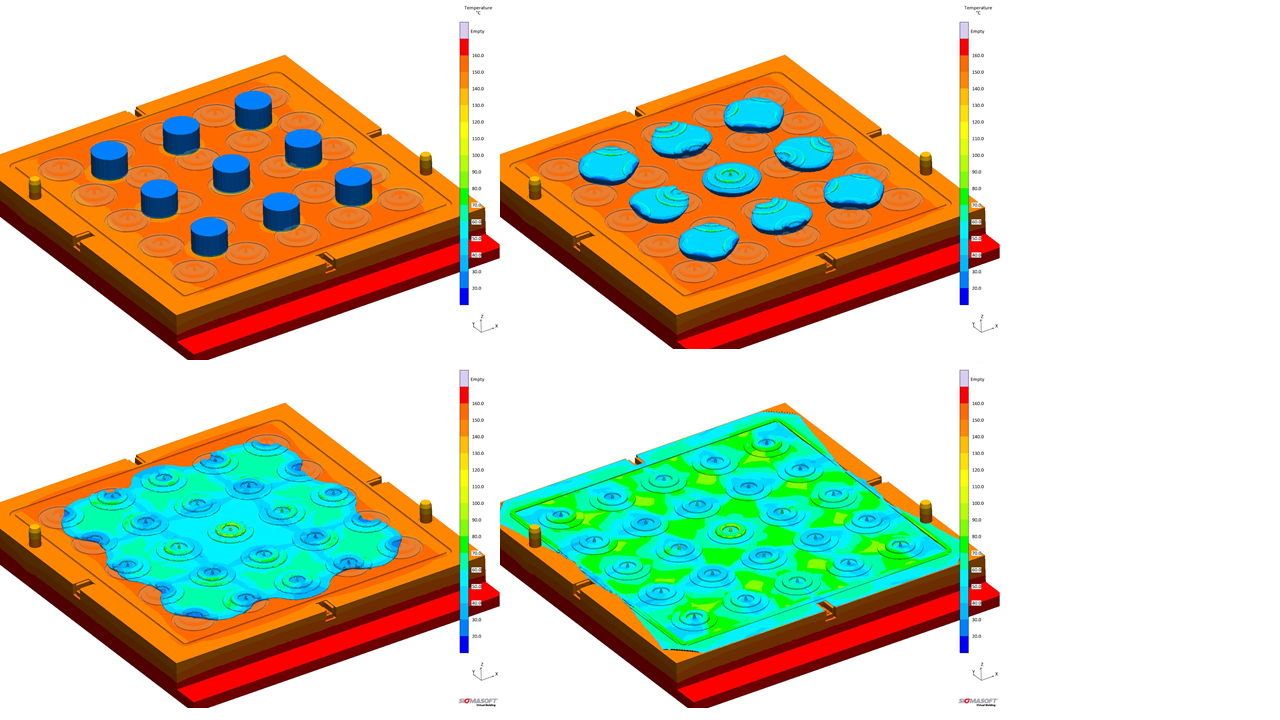

According to Sigma, Sigmasoft version 5.3.1 can help improve prediction of curing degree and cycle-data, while questions around shape, weight, position and number of preforms can also be investigated. The quality of the molded parts can be improved while reducing material consumption.

‘It sounds easy, but implementation was relatively complex,’ said SIGMA CTO Timo Gebauer. ‘The challenge is, that the cavity, or the room into which we inject, constantly changes during the closing of the mold. At the same time the inserted preforms are already heating up, are plasticizing and deforming.’

This story uses material from Sigma, with editorial changes made by Materials Today.