Solvay has developed a new continuous fiber prepreg suitable for compression molding.

According to the company, its Cycom EP2750 prepreg makes it possible to make quality aerospace components at a higher rate.

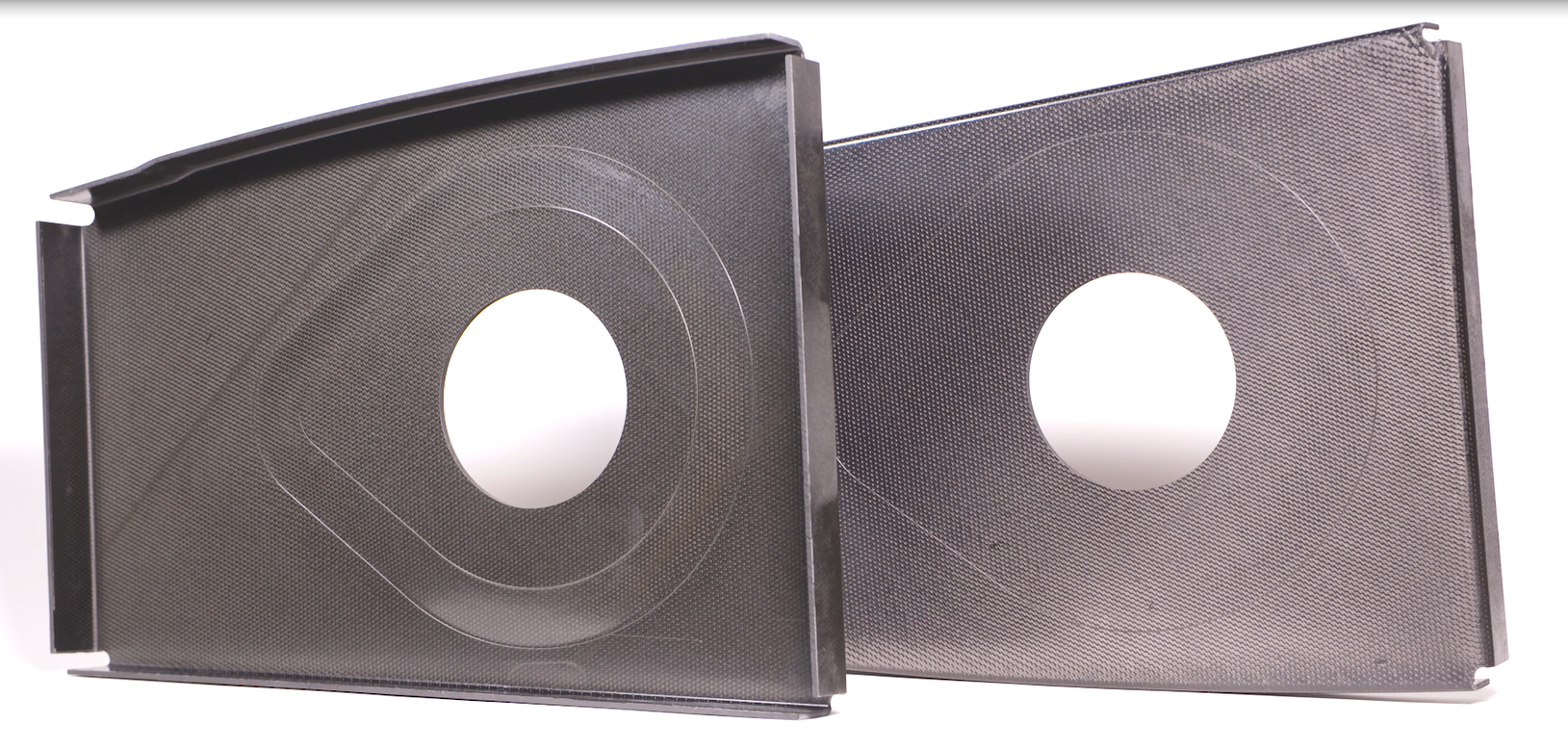

The material is reportedly applicable to primary and secondary structures and is compatible with multiple reinforcements. It offers high notched compression properties and enables the manufacture of complex geometries with a 30 minute takt time. Solvay says that Cycom EP2750 has already been used to make high quality small to medium size parts such as access panels, rib-shapes and C-frames. It can also be used with automated processing, making it suitable for high rate commercial aircraft programs as well as military and air mobility platforms.

Representative parts will be on display on Solvay’s stand at JEC World, the company said.

This story uses material from Solvay, with editorial changes made by Materials Today. The views expressed in this article do not necessarily represent those of Elsevier.