Delta Environmental Products had a problem. It was taking too long to make a key component in their wastewater solutions division. This product is a solution to the traditional gravity-fed sanitary sewer systems that is more ecologically sound. The problem was the facility tasked with making these parts couldn’t produce enough of a key product part to meet the demand. This resulted in the inefficiency of making more parts than ordered and keeping an expensive inventory to insure they had the parts when necessary. The primary problem Delta was having with previous production methods was the time it took to make each tank shell – one hour, which did not include moving the part the 300 ft between the production and assembly areas. The previous method also used a large amount of resin, which is generally a high cost item.

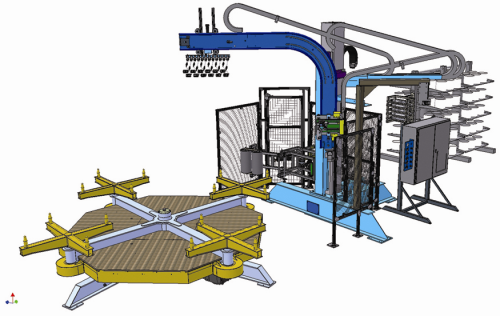

With the new automated Vertical Winding System from Magnum Venus Plastech, the resin and glass fibre are now applied in rings instead of swaths. This is a significantly faster and cleaner process requiring less drying. Production time to finish a tank went from 58 minutes down to 15 minutes.

Delta now produces 30 tanks in one day where they were only able to complete 18 before the new system was installed.