Victrex says that it plans to show its polyetheretherketone (PEEK) and polyaryletherketone (PAEK) polymer-based range at the K plastics show, taking place from 16-23 October in Dusseldorf, Germany.

This includes a food grade and additive manufacturing (AM/3D printing), composite, film, and gear materials.

The company’s products developed for use in 3D printing are filament for filament fusion (FF) or fine powder for laser sintering (LS), which it says produce better results with improved mechanical properties in printed parts and easier printing than past attempts to use PEEK in AM.

Victrex’s AE 250 composites reportedly have mechanical, physical and chemical resistance properties similar to members of the PAEK polymer family such as PEEK, but have a 40°C (104°F) lower crystalline melting temperature, at 305°C (581°F). The company says that the marerials offer up to 40% cost savings when compared to metals and are up to 70% lighter than metals with equivalent strength and stiffness. Recently the company won a JEC innovation award for an all-thermoplastic drive-shaft system overmolded with an integral gear.

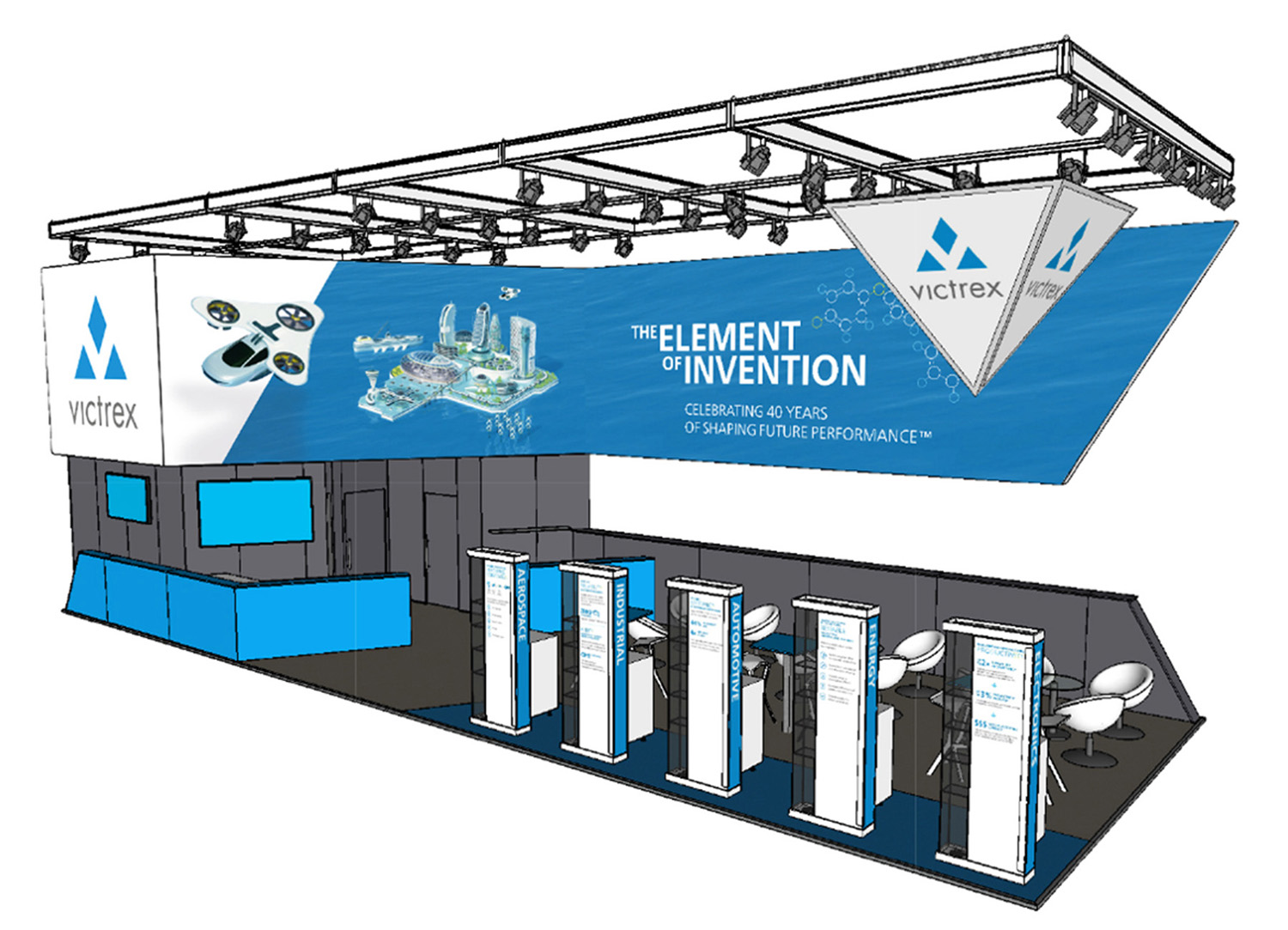

‘The invention of PEEK polymer has clearly had a very positive impact across industries and, in fact, across the globe,’ said Jakob Sigurdsson, Victrex CEO, in the run-up to the trade show.

This story uses material from Victrex, with editorial changes made by Materials Today. The views expressed in this article do not necessarily represent those of Elsevier.