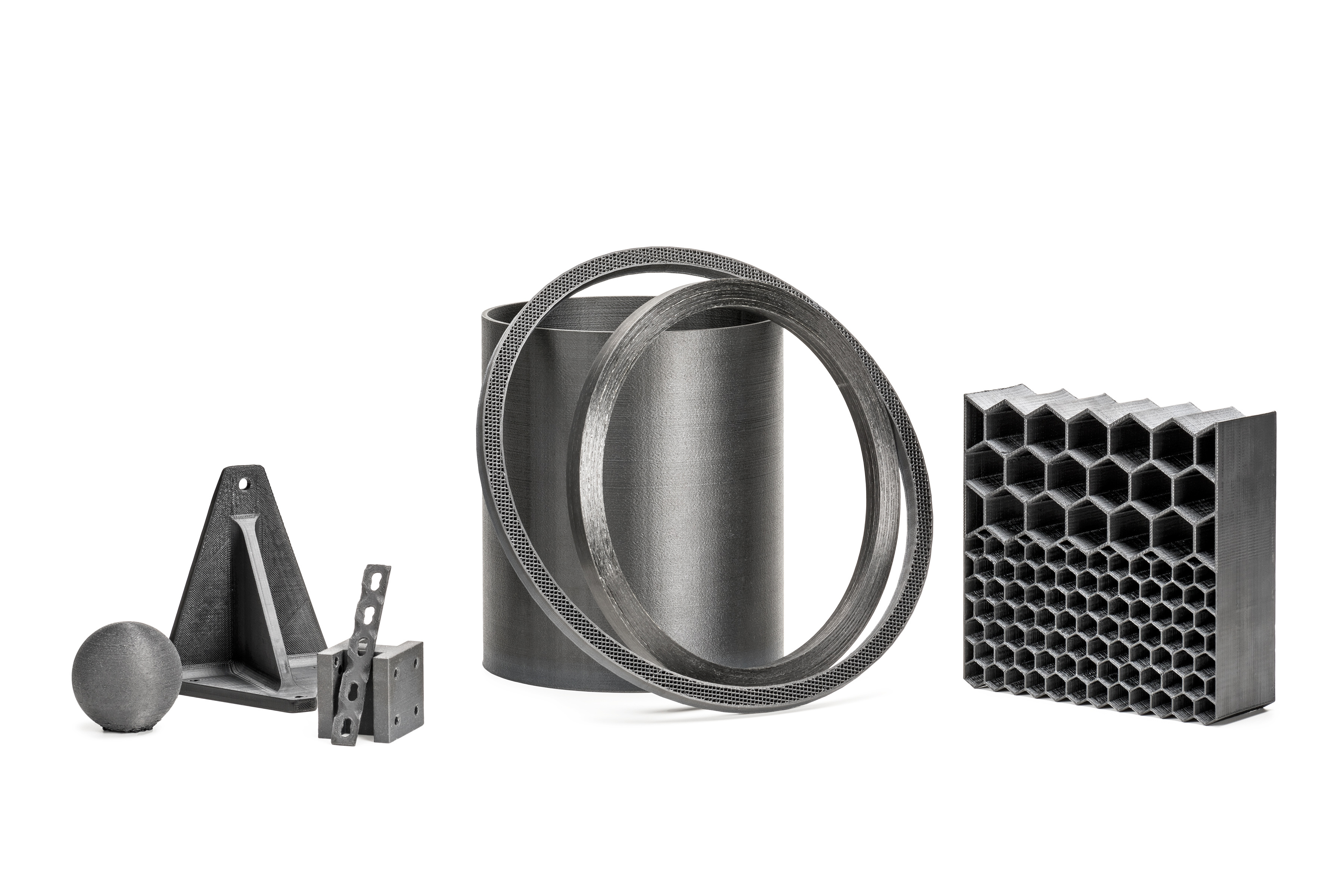

Arevo Labs has launched a range of materials to make to make 3D printed composite parts for a range of applications.

Available materials are PEEK (polyetheretherketone) and PAEK (polyaryletherketone) polymer based composite formulations which use a polymer matrix with carbon nanotubes, carbon fiber and glass fiber. According to the company, these composite materials have improved strength, stiffness, durability, wear resistance, chemical resistance, thermal stability and electrostatic discharge (ESD) properties.

The 3D printed parts also have improved mechanical properties using Arevo’s software algorithms that include additive finite element analysis and 3D printing.

‘We are excited to announce commercial availability of 3D printed PEEK and PAEK composite parts for the first time,’ said Hemant Bheda, CEO and founder of Arevo Labs. ’We have successfully developed end use applications in aerospace, single use medical devices, oil & gas and factory automation and are working closely with OEMs to scale up production.’

This story is reprinted from material from Arevo Labs, with editorial changes made by Materials Today. The views expressed in this article do not necessarily represent those of Elsevier.