TIXPREF composite fabrics are claimed to drastically reduce the cycle time by up to 50% (more for thin walled parts) required for press forming the fabrics into composite parts.

TIXPREF, a trademark of Tissa Glasweberei AG, is said to offer numerous advantages, including excellent mechanical properties that result from the high fibre content of up to 65%. Being thermoplastic, TIXPREF fabrics have a higher damage tolerance when compared to thermoset-based fabrics, high fatigue strength and stiffness, and excellent integration of the fibre with the matrix, resulting in a longer lifetime for the composite part, plus a reduction in its structural weight.

The fabrics are also easy and safe to handle, and thus well suited for automated processes and out-of-autoclave manufacturing methods.

"These characteristics exploit the outstanding performance properties of VICTREX PEEK polymer," says Albert Vodermayer, European Composites Market Leader at Victrex Polymer Solutions, which is the sole manufacturer and supplier of VICTREX PEEK (polyether ether ketone) polymer worldwide.

"They include a service temperature of up to 260°C (500°F), high resistance to harsh chemicals and solvents, and exceptional wear resistance, to provide superior mechanical properties under both static and dynamic load conditions. Further, Tissa fabrics are environmentally friendly since VICTREX PEEK polymer is solvent-free and recyclable and being thermoplastic in nature they can be stored at ambient temperature eliminating the need for expensive cooling and storage costs."

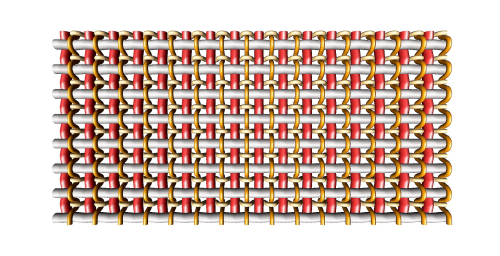

Tissa, a weaver of fibreglass textiles, has also developed non-crimp fabrics (NCFs) using VICTREX PEEK polymer.

Tissa's flexible production techniques allow multiple combinations of fibres and matrices. The resulting composite fabrics are tailored for use in aerospace, and in industrial and medical applications that do not have complex shaped parts, such as flat structures and panels. By heating the prepregs and press forming for two to three minutes, a panel thickness of just 2 mm is said to be possible.

Samples are available.