Victrex has reportedly joined forces with cabin interiors specialist Safran Cabin, to qualify thermoplastic composite parts for aerospace aircraft.

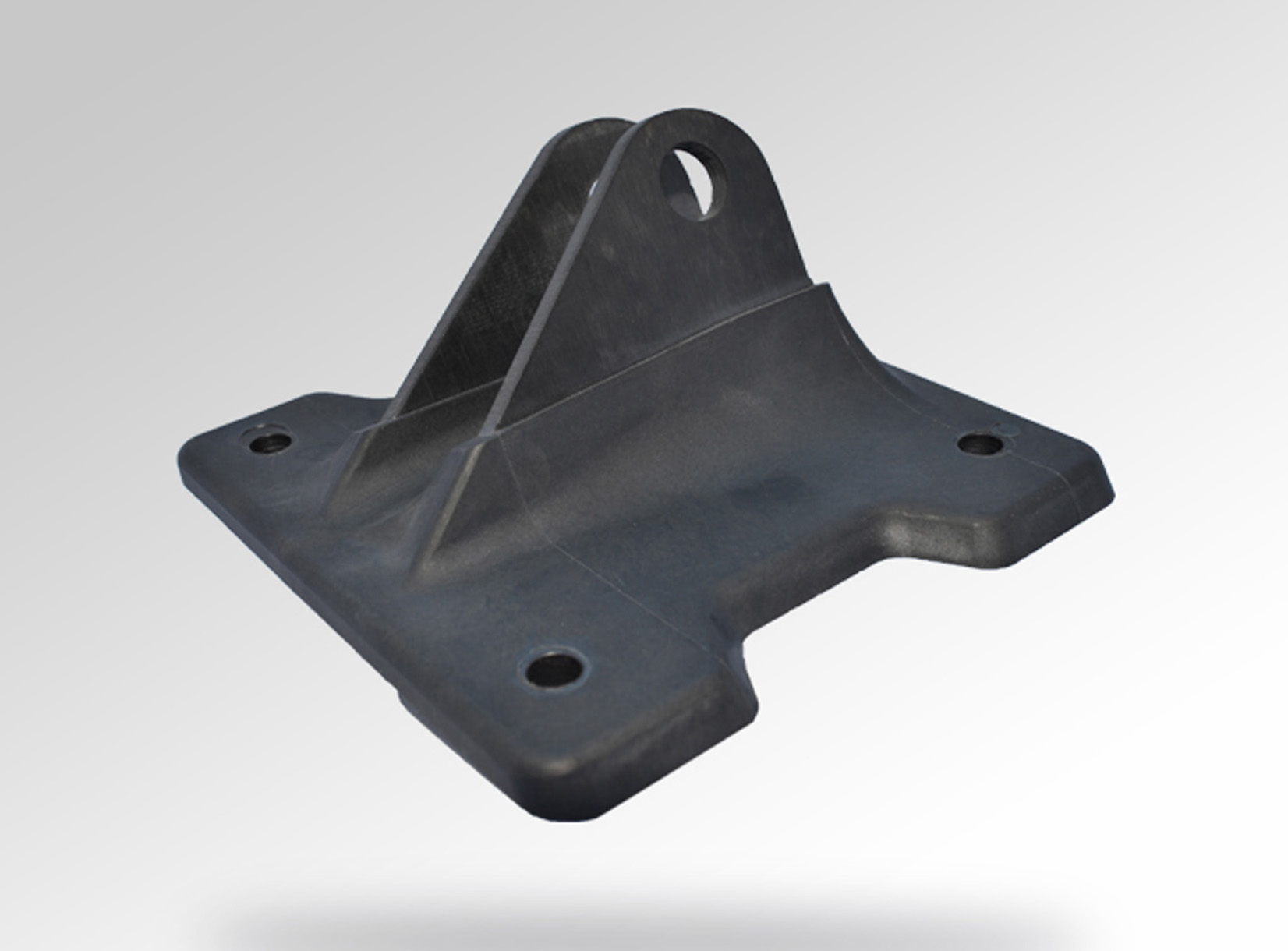

According to the companies, they aim to help cut planning and time-to-market of a range of brackets, including a hybrid overmolded aircraft cabin bracket made of Victrex AE 250 carbon fiber polyaryletherketone (PAEK) composite and polyetheretherketone (PEEK) polymer.

During the process, the thermoplastic composite is overmolded with PEEK polymer, a scalable, repeatable technology which could lower scrap rates, and increase cycle times, part consolidation, and reduction in secondary operations, Victrex says. In tests, structural aircraft parts produced from Victrex AE 250 via hybrid overmolding can reportedly withstand high levels of mechanical stress.

Compared to the original aluminium part, the prototype composite could result in 20% cost savings, 50% weight savings and a 5x better buy-to-fly ratio, the companies say.

Safran Cabin also plans to design parts and molds that are adaptable for multiple brackets and compatible with the same mold by combining mold-filling and structural simulation methods with various physical testing techniques to identify new technology failure modes and to streamline injection molding manufacturing and cost constraints.

‘We need to respond to many demands for aircraft brackets and similar structural parts, with each case having many loading, constraint, and exposure conditions,’ said Tyler Smithson, R&T engineer at Safran Cabin. ‘The key to success is to develop a flexible composite platform that can be used for multiple projects, lowering our part count and design complexity, cutting time-to-market, speeding time-to-revenue.’

The companies aim to put the composite bracket in service later in 2019.

This story uses material from Victrex, with editorial changes made by Materials Today. The views expressed in this article do not necessarily represent those of Elsevier.