Composites Evolution has launched a new variable temperature cure prepreg system.

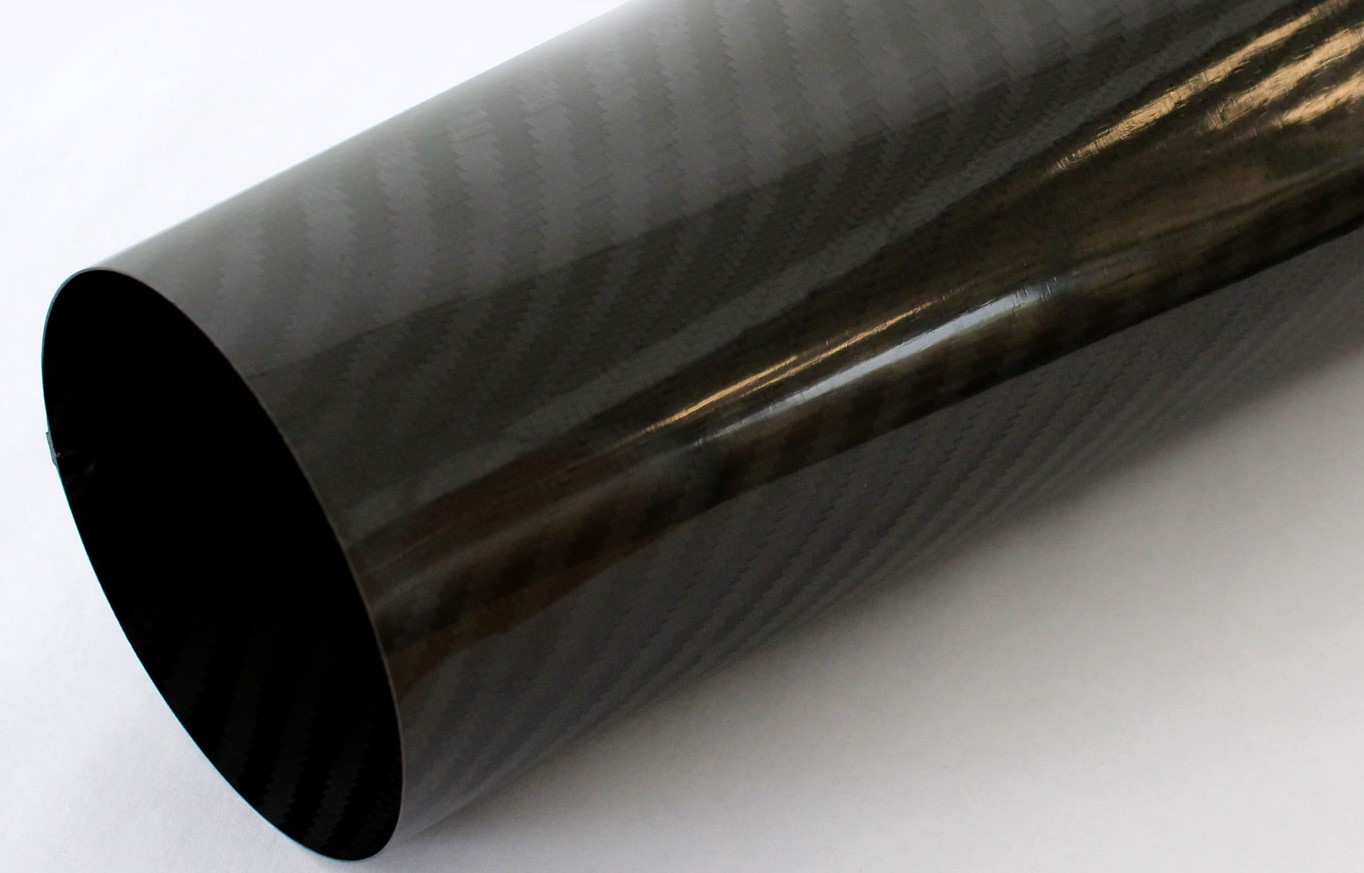

According to the company, Evopreg EPC200 is part of its Evoprep EPC component epoxy range and allows molders to achieve a better visual quality surface finish from a variety of processes at a range of temperatures.

‘Evopreg EPC 200 is primarily aimed at molders using low-temperature, out-of-autoclave molding processes, who want to produce components with an exceptional surface finish,’ said sales and marketing director Ben Hargreaves. ‘However, its flexible cure profile also makes it ideally suited to rapid processing at higher temperatures, which means that the same level of performance can be achieved in just a fraction of the time.’

Evopreg EPC200 is based on a toughened epoxy resin system and is suitable for curing between 65°C and 120°C, using vacuum bag/oven, autoclave or press molding.

Composites Evolution’s Evopreg EPC component resins are available with a range of carbon, glass, aramid and ampliTex flax reinforcements.

This story uses material from Composites Evolution, with editorial changes made by Materials Today. The views expressed in this article do not necessarily represent those of Elsevier.