Advances in prepreg technology have produced materials that do not require refrigeration for storage, prepregs with longer shelf life, and products that cure at lower temperatures without the need for autoclave techniques. A wider selection of reinforcements and polymer matrix resin systems present more opportunities for composites production using prepreg materials than ever before.

Global shipments of prepregs have been growing at a rate of more than 10% a year since 2002, more than doubling in volume from 2002 to 2007, according to Lucintel’s Global Prepreg Market 2008-2013: Trends, Forecast and Opportunity Analysis. The level of prepreg demand has “steadily increased in striking parallel with the number of industrial applications using composite materials,” the report notes.

“From aerospace to sporting goods to wind energy, prepreg is rapidly gaining acceptance as a material of choice for its high performance characteristics,” says Lucintel.

Prepreg cost advantages

While the initial cost of prepreg materials is higher than materials used in traditional wet lay-up and spray-up processes, lower fabrication costs, faster production and other benefits that prepregs offer can reduce and even eliminate the cost differential. Cost advantages of using prepregs include reduced labour through the elimination of manual wetting-out steps, reduced rework to redistribute resin (since resin is already uniformly distributed), and reduction in clean-up operations associated with wet processes.

Manufacturers of prepregs, known as prepreggers, supply rolled materials produced from various combinations of reinforcement fibres and matrices in a partially cured (B-stage) form. Thermosets are the most prevalent, with the primary three being epoxy, phenolic and bismaleimide resins. High-performance thermoplastics are also used to produce prepregs.

Computer-driven nesting and cutting machinery as well as automated tape laying and fibre placement systems reduce manual labour and waste while shortening assembly time. Fiberforge, a Colorado, USA-based technology company specialising in advanced thermoplastic composites, has developed and patented technology for a high-volume production system using thermoplastic prepreg tape. An automated lay-up process produces near-net-shape tailored blanks, which are heated and formed into parts in a high-pressure thermoforming press.

The Fiberforge Relay™ manufacturing system is designed for cost-effective production of lightweight composite structures in high volumes with low scrap. In March, the company announced a licencing agreement with Oribi Manufacturing of Denver, Colorado, to utilise the Relay station in the manufacture of composite parts for the outdoor, sporting goods, medical and industrial markets.

Classification of prepregs is by aerial weight as grammes per square metre (g/m2) or ounces per square yard (oz/yd2). The materials are also grouped by cure temperature: room temperature, 250°C and 350°. Vacuum bag, pressure bag and autoclave processing techniques are used to consolidate and cure prepreg materials after placement in a tool or onto a mandrel.

Top prepreg suppliers

Among the leading prepreggers are Hexcel Corp, Advanced Composites Group (ACG), Cytec Industries, Gurit AG, Toray Industries and TenCate Advanced Composites. Last year Hexcel was awarded a contract worth about US$4 billion through 2025 to supply primary structure prepreg for the Airbus A350 XWB aircraft.

Cytec and Hexcel are the largest carbon prepreg suppliers to the aerospace industry, although with the adoption of carbon prepreg on the new Boeing 787 Dreamliner, market share will shift to Toray as production ramps up, according to aerospace consultancy AeroStrategy.

At the JEC Composites Show 2009 in March, Hexcel promoted its new HexPly® M56 out-of-autoclave (OOA) prepreg for aerospace composite structures. Requiring only an oven cure at 135-180°C (275-356°F) under vacuum, the material is available with woven carbon, unidirection (UD) carbon tape, woven glass and metallic mesh reinforcements.

HexPly M56 is said to provide 30-day tack life at room temperature and is suitable for hand lay-up and automated processes.

ACG, a member of the Composites Division of Umeco plc, also promoted its OOA aerospace prepreg technology at JEC. ACG’s dual-cure prepreg MTM44-1 (130-180°C [266-356°F]) was qualified by Airbus Industrie in 2008 for structural applications in tape and fabric formats. The material is said to be optimised for low-pressure vacuum bag processing. ACG also offers other OOA systems for a variety of applications.

Cytec Engineered Materials promoted the benefits of its new OOA-capable prepreg system CYCOM 5320, with a toughened epoxy resin, at the JEC show. The material is said to provide mechanical performance equivalent to 180°C autoclave cured toughened epoxy systems. In addition to tailorable handling properties, a variable vacuum bag cure cycle (from 90°C for 8 hours to 120°C for 2 hours) provides flexibility in processing, notes Cytec.

Gurit has developed PB1000 prepreg for aircraft interior applications. The product utilises a modified benzoxazine resin exhibiting no formaldehyde or phenol residue and features a non-volatile rapid cure to produce a void-free, non-porous surface, says Gurit. Another prepreg product, EP137-CR527, utilises UD carbon fibre reinforcement and is said to be well-suited for aircraft structural interior applications. The prepreg, introduced for the Airbus A380 passenger floor, is designed especially for automated lay-up processing.

TenCate has launched a new epoxy prepreg for space and satellite structural applications, RS-36, calling it a value-based alternative to cyanate ester prepregs. Curing at 177°C (350°F) for 90 minutes, the product is said to provide outstanding moisture resistance and low outgassing. Also new is TC550, a toughened epoxy hybrid prepreg designed for aircraft interiors and ducts. It is a non-halogenated, non-phenolic system that meets all European Union (EU) requirements with respect to REACH (Registration, Evaluation and Authorisation of Chemicals) as well as all banned, targeted and restricted substances, reports TenCate.

Another product, TC250, which is currently undergoing qualification, is a toughened 121°C (250°F) service epoxy prepreg designed for vacuum bag curing. It is designed to meet the needs of the general aviation, unmanned vehicle and business aircraft markets in primary and secondary structure. Qualification is expected to be completed before the end of 2009. A new Aerospace Selector Guide describing TenCate’s prepregs and other products, can be downloaded from the company’s website.

Wind and sea energy

Gurit has developed prepreg products for demanding structural applications in the wind energy and emerging ocean energy applications. For thick laminate sections in the production of spar caps of wind turbine blades, Gurit offers SparPreg™. This UD prepreg is said to provide low void content without the need for debulking or additional dry fabric reinforcement to aid air removal.

SparPreg has been specially formulated to achieve the outstanding in-cure and mechanical performance of the WE91 prepreg systems, relates Gurit. For in-mould surfacing of wind turbine blades, the company offers SPRINT® IPT, a multi-layer product supplied on a roll. It is comprised of SPRINT Triax material and a new high-performance surfacing film which, when cured, provides a tough and abradable surface that can be painted directly.

Following successful product trials, a Chinese manufacturer of wind turbine blades recently signed a contract to purchase prepreg materials and formulated products from Gurit’s production site in Tianjin, China. The prepregger relates that it is well positioned to meet the growing demand for wind energy generation across China and Asia. It can offer locally manufactured prepregs along with full local technical and commercial support.

Hexcel also operates a wind energy prepreg manufacturing plant in Tianjin. Early this year the company broke ground for another similar facility in Colorado, USA. Hexcel offers a range of products for wind turbine blades, including a new surfacing prepreg for wind energy applications. HexPly® XF2P provides a ready-to-paint surface that is said to be tough and durable without the need for gel-coat.

The use of prepregs is also growing for automotive applications. Hexcel has developed a range of composites specifically tailored to the requirements of the automotive industry, including HexPly M49 prepreg, which is said to be well-suited for body parts and interior components. A surfacing film, HexPly XF3, provides a ready-to-paint surface finish and is compatible with most epoxy prepregs, adapting to a range of cure cycles, from 100-140°C (212-284°C).

ACG prepreg technology played a role in the construction of the world’s largest commercial-scale tidal energy system, SeaGen, operating in the mouth of Northern Ireland’s Strangford Lough. ACG’s Variable Temperature Moulding VTM®260 Series prepregs were utilised for the manufacture of the 65 mm thick structural spars, providing the required high strength and stiffness but with minimal mass, notes ACG.

The scale of the project meant that excellent handling and out-life characteristics were significant factors in the prepreg selection. Vacuum-only processing was chosen for curing the large parts. Optionally, VTM260 prepregs can be autoclave cured.

Bullet-stopping prepregs

Ballistic prepreg materials, designed to provide protection from bullets, projectiles, and explosions, are offered by several manufacturers. High-performance bullet-resistant prepreg materials, sheets and moulded shapes are produced by Norplex-Micarta High Performance Thermoset Composites in Postville, Iowa, USA. Materials in the ShotBlocker™ line are said to be the only commercially available Class 1-A fire-rated, projectile-resistant building material available. Applications include armoured vehicles, blast-resistant doors and security products.

Norplex-Micarta’s glass-fabric-based ballistic protection material is available in five levels of bullet resistance, offering performance comparable to conventional S-2 glass laminates, which cost considerably more, says the company. ShotBlocker materials are designed to provide exceptional structural strength plus ballistic and ricochet resistance against weapons’ fire, blasts and fragmentation. These materials are well-suited for architectural applications which could not be achieved with ballistic steel armour plate. ShotBlocker provides the same level of protection as steel at one-third the weight, says the manufacturer.

At the JEC show, ACG exhibited a ballistic prepreg application – a spall liner manufactured at Permali Gloucester Ltd, a UK supplier of lightweight armour systems. A hot press moulding technique was used with ACG’s MTM82 Phenolic resin/S2-glass® prepreg in production of the component. The materials and process are in full-scale production, and parts have been supplied for fitment to an in-service fleet of vehicles, ACG relates.

Tooling prepreg

Prepreg materials are often used in the construction of composite tooling. Hexcel displayed tools made with its HexTOOL® machinable composite tooling material at JEC and introduced a new carbon fibre/epoxy product, HexTOOL M81. Composed of prepreg mat bundles in a quasi isotropic orientation, the material is designed to be autoclave cured at 125°C (260°F) for six hours, followed by an OOA post-cure of two hours at 205°C (400°C). It has a storage life of 12 months at -18°C (0°F) or lower and an out-life of 21 days.

|

Prepreg materials are manufactured by combining reinforcement fibres or fabrics with specially formulated pre-catalysed resin systems using machinery designed to ensure consistency. Prepregs are used to produce composites faster and with less mess than wet lay-up systems. Covered by a flexible backing paper, prepregs can be easily handled and remain pliable for a certain time period (out-life) at room temperature. Curing of prepreg laminates is achieved by heating at elevated temperatures under pressure according to the manufacturer’s specifications. Conventional prepregs are formulated for autoclave curing, while low-temperature prepregs can be fully cured by using vacuum bag pressure alone at much lower temperatures. Prior to use, prepregs are typically stored at sub-freezing temperatures to prolong their useable life. According to Gurit, which offers prepreg materials for a wide range of applications and cure temperatures, the accuracy of the machinery used to produce prepregs enables the use of very tough and strong resin systems that would be too high in viscosity to be impregnated by hand. In addition, laminates produced from prepregs have more consistent and higher fibre content than can be achieved using wet layup techniques, notes Gurit. In a handbook introducing its SP Prepregs, Gurit explains that the viscosity of a prepreg resin system affects many processing properties, and it is strongly affected by temperature: “At 20°C (68°F) a prepreg resin may feel almost solid, giving the prepreg its ‘dry’ buy tacky feel. On heating, the resin viscosity will drop dramatically, allowing it to flow around fibres and giving the material the necessary flexibility to conform to mould shapes. As the prepreg is heated beyond a certain point (the activation temperature), the catalysts within it will begin to react and the crosslinking reaction of the resin molecules will accelerate. The progressive polymerisation increases the viscosity of the resin in the prepreg until it has passed a point where it will not flow at all. The reaction then proceeds to full cure.” |

HexTOOL M81 is much thicker than standard composite tooling prepregs and does not require strict adherence to a lay-up schedule, thanks to the quasi isotropic properties, says Hexcel. It is formulated to withstand more than 100 part-cure cycles at 120°C. Also available is HexTOOL M61, which can withstand several hundred autoclave cycles at 180°C, says Hexcel, noting that data generation is ongoing and, once complete, will be able to confirm more precisely the maximum tool life of both systems.

ACG offers its patent-pending DForm™ Deformable Composite System (DCS) for tooling. The prepreg material combines the conformability of a short-fibre moulding compound with the directional characteristics of a high-performance, long-fibre composite, says ACG. First previewed at last year’s JEC show, DForm has undergone extensive market testing, demonstrating time savings and other benefits over wet lay-up and resin infusion tooling systems, notes the company.

More recently, new custom-built production equipment has been installed at ACG’s Heanor, UK, manufacturing facility to further enhance the product and accelerate productivity rates to satisfy anticipated market demand, the company reports. The new equipment will also facilitate further development of the DForm system for structural applications. According to ACG, DForm is particularly suited to the manufacture of composite tooling, offering a number of advantages over standard long-fibre woven fabric prepreg and random short-fibre and infusion tooling systems.

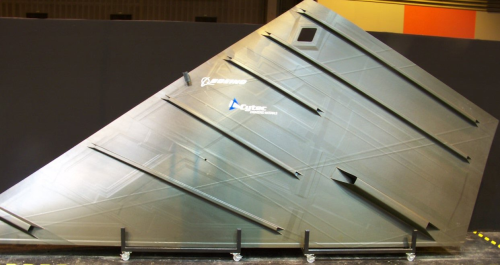

Another product for tooling from ACG is ZPREG®, a partially impregnated, rapid-laminating system specifically formatted for rapid tool construction with no intermediate debulking cycles. ACG reports that it recently completed the manufacture of a large rear fuselage tool using ZPREG tooling surface plies and high-temperature tooling bulk ply. Autoclave tested for vacuum integrity up to 190°C (375°F), the tooling showed no leakage and produced an excellent surface finish, relates ACG.

Amber Composites, Nottingham, UK, known for its Multipreg™ HX series epoxy tooling products, also offers a low-temperature-curing tooling prepreg formulated with nano-modified epoxy resins. The product, HX90N, is said to provide benefits previously unattainable, including very low thermal expansion, improved flatness and pin-free surface finish, making the material superior to aluminium and epoxy tooling board, the company relates.

HX90N is said to be easy to use, offering excellent drapeability and allowing complex shapes to be formed. The improved surface finish can reduce preparation time necessary to achieve Class A surfaces as well as reduce the amount of primer needed, decreasing the weight of the finished product, notes Amber Composites. Due to less surface pitting, tool life is also extended, the company adds.

Amber Composites has partnered with European tooling and prototyping leader Axson Technologies to offer a range of tooling and component products, including Amber’s HX series tooling prepreg, in Germany, France, Italy, Spain and Portugal. Focus areas include automotive, aerospace, marine and structural bonding applications.

Boron-reinforced prepregs

Prepregs reinforced with boron and graphite fibres commingled as a single ply are available from Specialty Materials in Lowell, Massachusetts, USA. Hy-Bor® Prepreg Tape combines boron fibres with graphite prepreg in an epoxy matrix to produce high-performance materials with exceptional properties, offering an alternative to carbon fibre. By altering the spacing of the boron fibres in the prepreg, performance properties and material costs can be tailored to meet the needs of a variety of demanding applications, says Specialty Materials.

The standard Hy-Bor product utilises Mitsubishi Rayon’s MR-40 graphite fibre with 4-mil (0.10 mm) diameter boron fibre and 120°C (250°F)-cure epoxy resin. Hy-Bor can also be manufactured to incorporate any commercially available graphite prepreg. Commingled, each fibre contributes to and shares the load, says the manufacturer, noting that the graphite and boron fibres are matched to yield improved balance between tension and compression strength and modulus. According to the manufacturer, Hy-Bor provides the maximum compression strength of any continuous filament-based composite material. The product can be prepregged to the customer’s resin preference.

|

Prepreg roll and sheet materials for ballistic applications are manufactured at Norplex-Micarta facilities, where Randy Nesbit, senior marketing specialist, explained the process to Reinforced Plastics. This series of photographs shows ballistic sheet material being manufactured. To start, woven fibreglass is fed into a bath of phenolic resin and carried through a series of rollers to squeeze off excess resin. The wetted-out fabric progresses through a 46 m (150 ft)-long oven, which burns off volatiles, leaving it in a semi-cured state. After exiting the oven, the material is inspected to ensure consistent resin content throughout then sheared to the required dimensions. The sheets are stacked and weighed to determine that the laminate has the correct number of layers to produce the desired final thickness. Then the stack is pressed into a solid sheet to be used in ballistic construction applications. Sheet thicknesses to achieve five levels of bullet resistance range from ¼ to 1-3/16 inches (6.35-31.2 mm). |

A unique epoxy prepreg technology from TCR Composites in Ogden, Utah, USA, offers long shelf life at room temperature – up to 12 months at temperatures not greater than 24°C (75°F). The company offers a line of TCR™ prepregs made with a patented epoxy resin system with extended out times at ambient temperature. The materials offer flexible cure cycles without the need for vacuum bag or autoclave techniques. Applications include automotive, recreational vehicles, medical and industrial products.

The TCR materials are available in a variety of fibres, from E-glass to high modulus carbon, in tow, braid, unidirectional tape and woven fabrics. Resin content, resin flow during cure and tack levels can be modified to suit processing requirements. TCR high-performance towpregs, well-suited for the manufacture of pressure vessels, are designed for high throughput (up to 275 m [900 ft] per minute) for filament winding operations. Tow can be impregnated from 6K to 60K standard modulus to high modulus carbon fibres as well as glass, basalt, aramid and PBO (poly-p-phenylene benzobisoxazole) with equivalent cross sections.

Another innovative prepreg product is manufactured by Mitsuya, a specialist in carbon fibre materials, using high-performance APTIV films made with Victrex® PEEK™ (polyetheretherketone) polymer reinforced with carbon fibre tows. The result is a lightweight, unidirectional thin-sheet prepreg offering high heat resistance and strength with excellent processing flexibility. By utilising APTIV films, Matsuya can produce extremely thin sheets (40 µm or less), which offer superior multi-axial layering qualities for excellent design flexibility, notes Victrex.