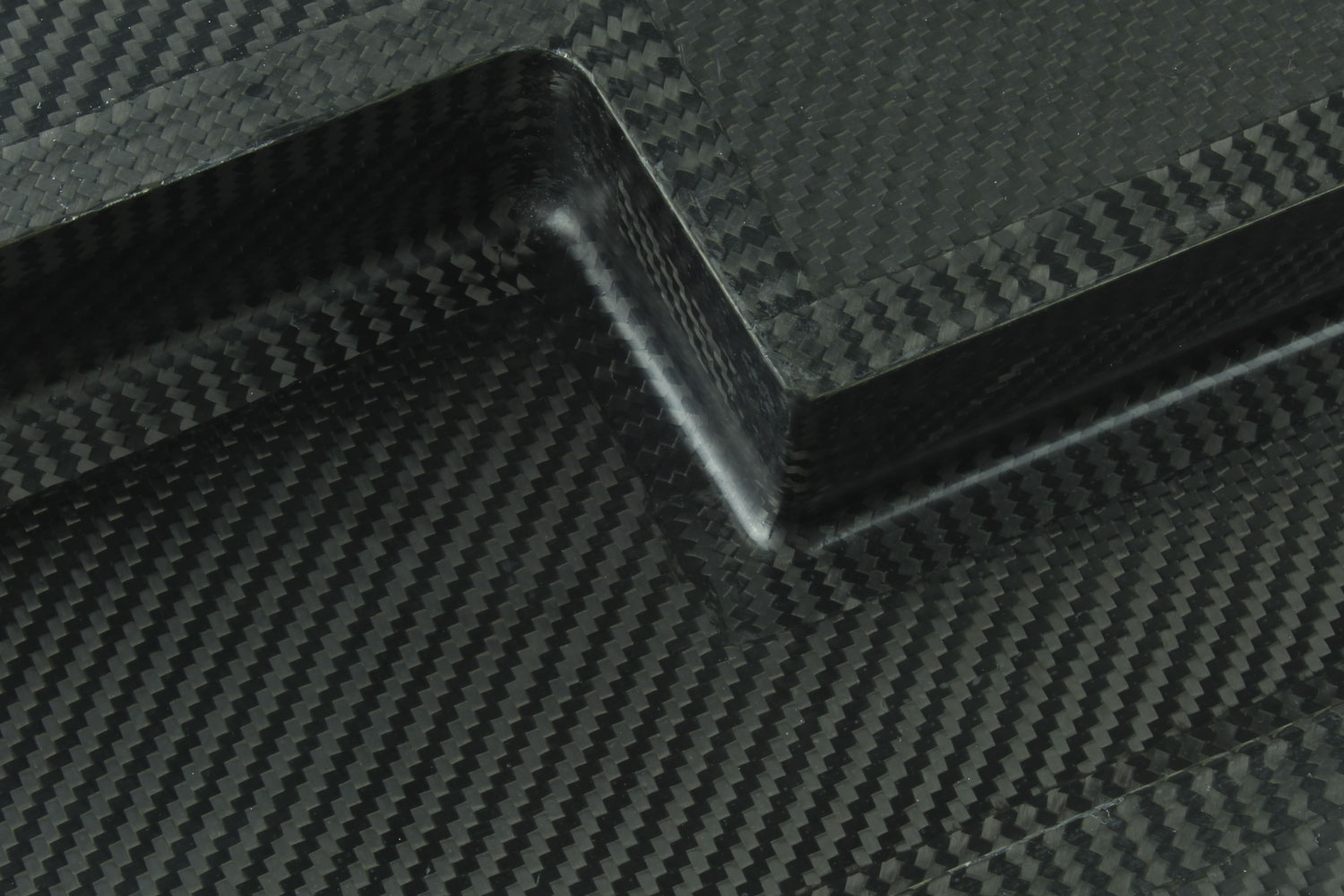

Composites Evolution has developed a new 50°C, 12-hour cure tooling prepreg for tools with improved surface finish dimensional stability.

The prepreg will be launched at the JEC World composites show.

According to the company, the prepreg has an extended out-life, allowing large or complex tools to be manufactured with less waste. The material has improved tack and drape for easy lay-up, improved release from patterns and high service temperature performance (180°C after post-cure), Composites Evolution said.

‘Tools can now be laid-up and cured overnight, ready to be used the following morning,’ said sales and marketing director Ben Hargreaves. ‘The low temperature cure ensures improved dimensional stability, while our proprietary resin formulation ensures that our customers don’t have to compromise on outlife.’

Composites Evolution’s EPT tooling resins are available with a range of carbon, glass and flax reinforcement fabrics.

This story uses material from Composites Evolution, with editorial changes made by Materials Today. The views expressed in this article do not necessarily represent those of Elsevier.