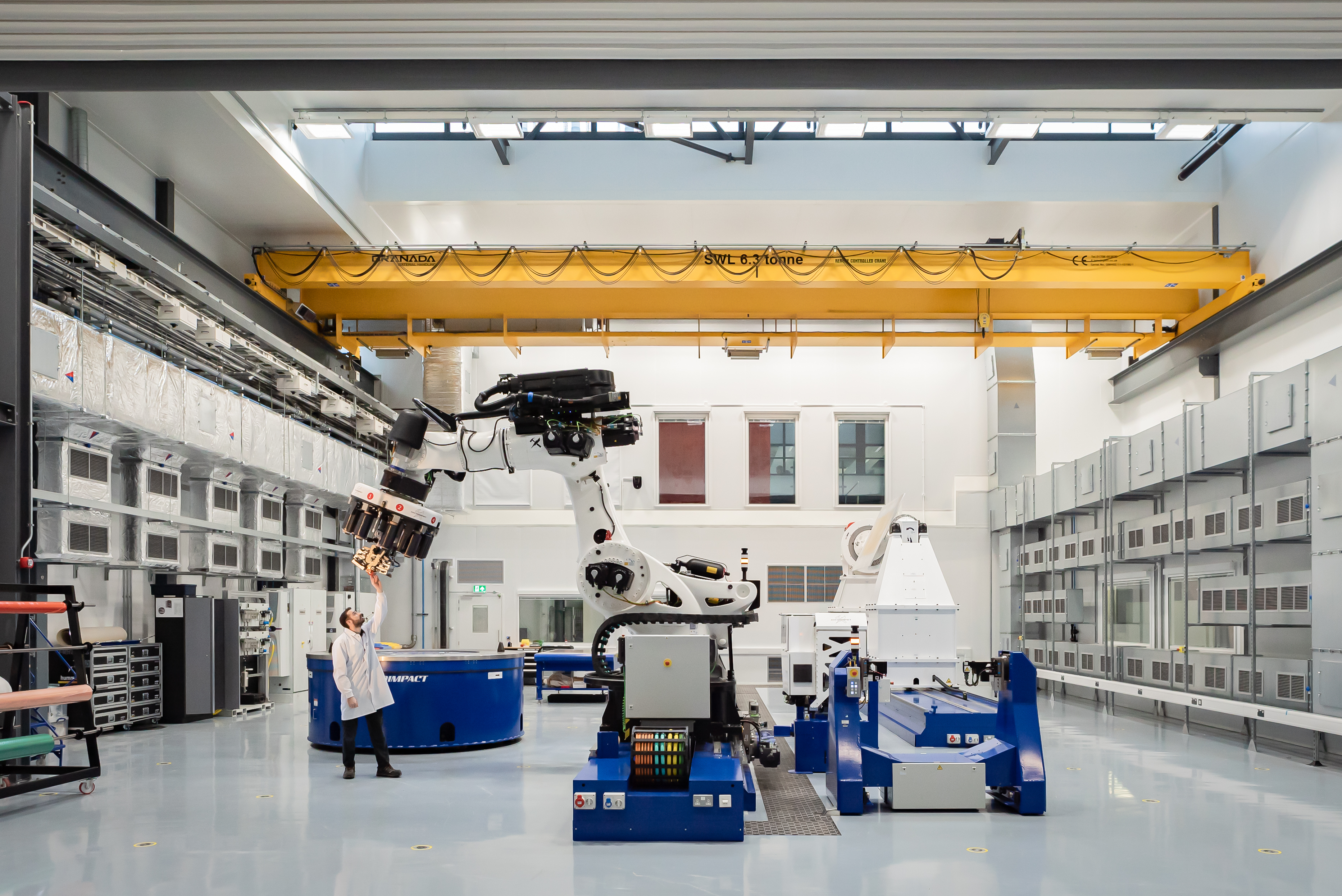

The National Composites Centre (NCC) in the UK has installed a new automated fiber placement-automated tape lay up (AFP-ATL) cell. The cell, created in partnership with tooling manufacturer Electroimpact combines both AFP and ATL in a single system. According to the NCC, the two processes can be used individually or together to make large, complex structures with minimal downtime. The AFP process head utilises eight tows, each measuring 12.7 mm wide, with either an infrared heater to manufacture thermoset composites, or humm3 flash technology developed by Heraeus Noblelight Ltd and tested at the NCC to manufacture thermosets of low temperatures (30-60°C) and high temperature thermoplastics or bindered dry fiber (100-300°C). The Automated Tape Layup (ATL) head can deposit tapes of 75, 200 or 300 mm widths using the same heating systems and material processing capability as AFP. The cell features vertical and horizontal rotators that can create geometries such as convex and concave panels, large scale diameter pipes, spars or barrel/tower structures. The rotators enable components of up to 4.6m diameter, and 7 m in length to be manufactured. The cell's flat tables also allow for smaller scale analyses such as material testing or prototype trials to de-risk programs and build knowledge prior to larger scale projects. ‘The NCC's AFP-ATL capability is a perfect test bed for automated composite manufacturing at a medium to large scale level,’ said Eva Sastres Collardo, automation manager at the NCC. ‘The system will enable new and existing markets to build up their innovation platforms from the ground up, from small scale prototyping and material testing through to full scale demonstrators and data analytics.’ ‘Through collaboration, the NCC believe that AFP-ATL has the ability to reduce the barrier to entry to these game changing technologies and expand the composite market into other areas such as renewable energy, oil & gas, construction and rail,’ a press release added. The center has now installed ten fully digital automated composite manufacturing machines worth £36.7 million in the past 18 months.

This story uses material from the NCC, with editorial changes made by Materials Today. The views expressed in this article do not necessarily represent those of Elsevier.