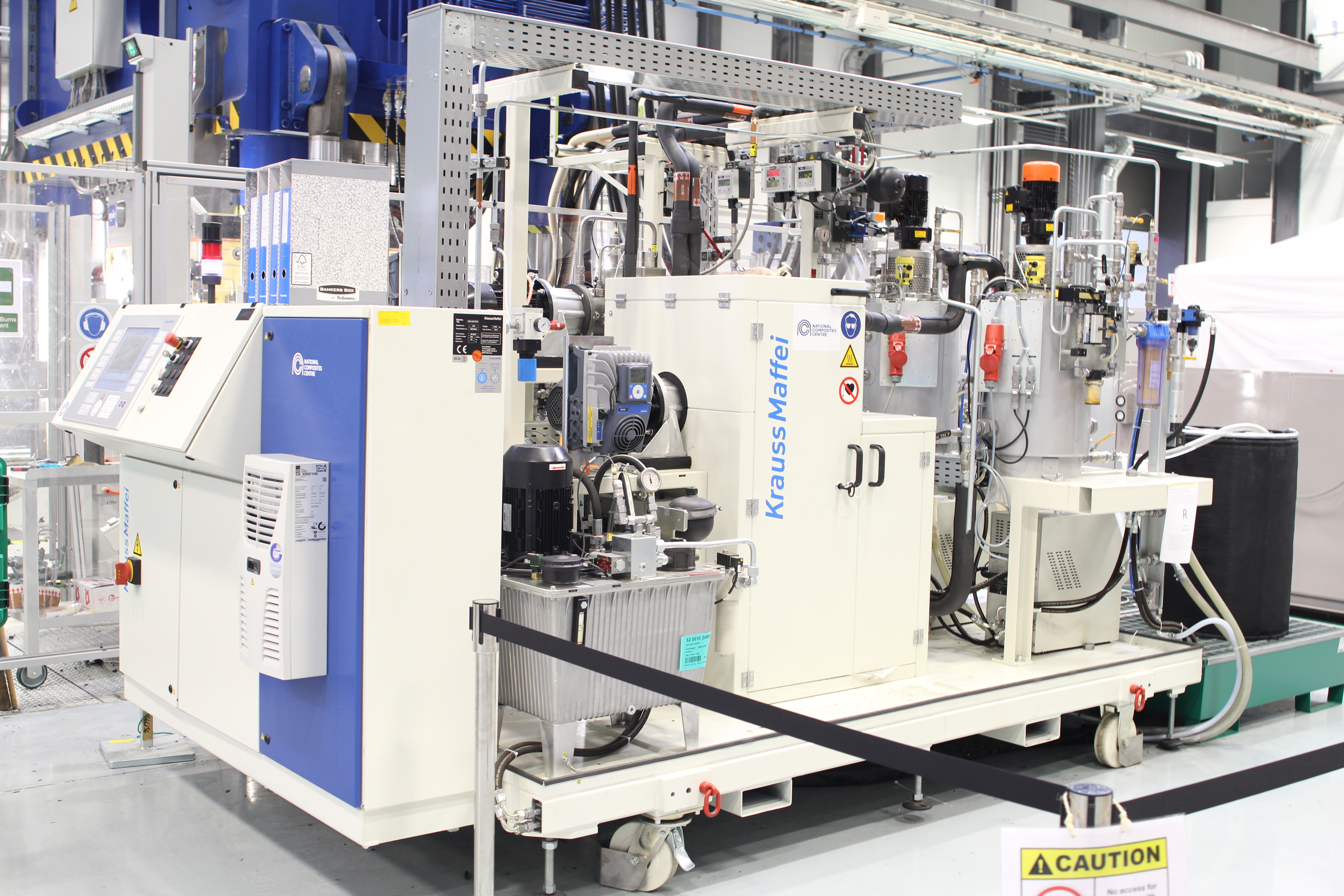

The UK’s National Composites Centre (NCC), based in Bristol, reports that has put a new KraussMaffei RimStar Compact 4/4/4 into operation. The mixing and metering machine is equipped with two mixing heads, so that it can process both epoxy resin and polyurethane (PUR) in high-pressure resin transfer molding (HP-RTM) and enables short cycle times for production of lightweight components.

‘High-pressure injection using the RimStar Compact allows us to process fast-reacting resin systems. This shortens cycle times, enabling us to produce fiber-reinforced components in large quantities,’ said Wolfgang Hinz, product and sales manager business unit composites and surfaces at KraussMaffei. ‘Previously, the HP-RTM process primarily used epoxy resin as the matrix material. Recently, however, an increasing number of components are being made of polyurethane in the HP-RTM process. Because the RimStar Compact 4/4/4 can process both matrix systems, it gives the NCC and its member companies great flexibility for carrying out application-oriented test series.’

At the NCC, new production methods are being developed for composite materials and advanced into industrial series production, with research focused on areas including the automated manufacturing of fiber preforms, component manufacturing using autoclaves and compression molding and post-mold processing of the fiber-reinforced components. The total floor space of the institute has been expanded to 8500 m² and the RimStar Compact 4/4/4 was installed as part of this expansion.

This story uses material from the NCC, with editorial changes made by Materials Today. The views expressed in this article do not necessarily represent those of Elsevier.