Toray Advanced Composites has partnered with two automation companies to develop a process which can make large thermoplastic composite parts at deposition rates of up to 4000 inches (100 m) per minute.

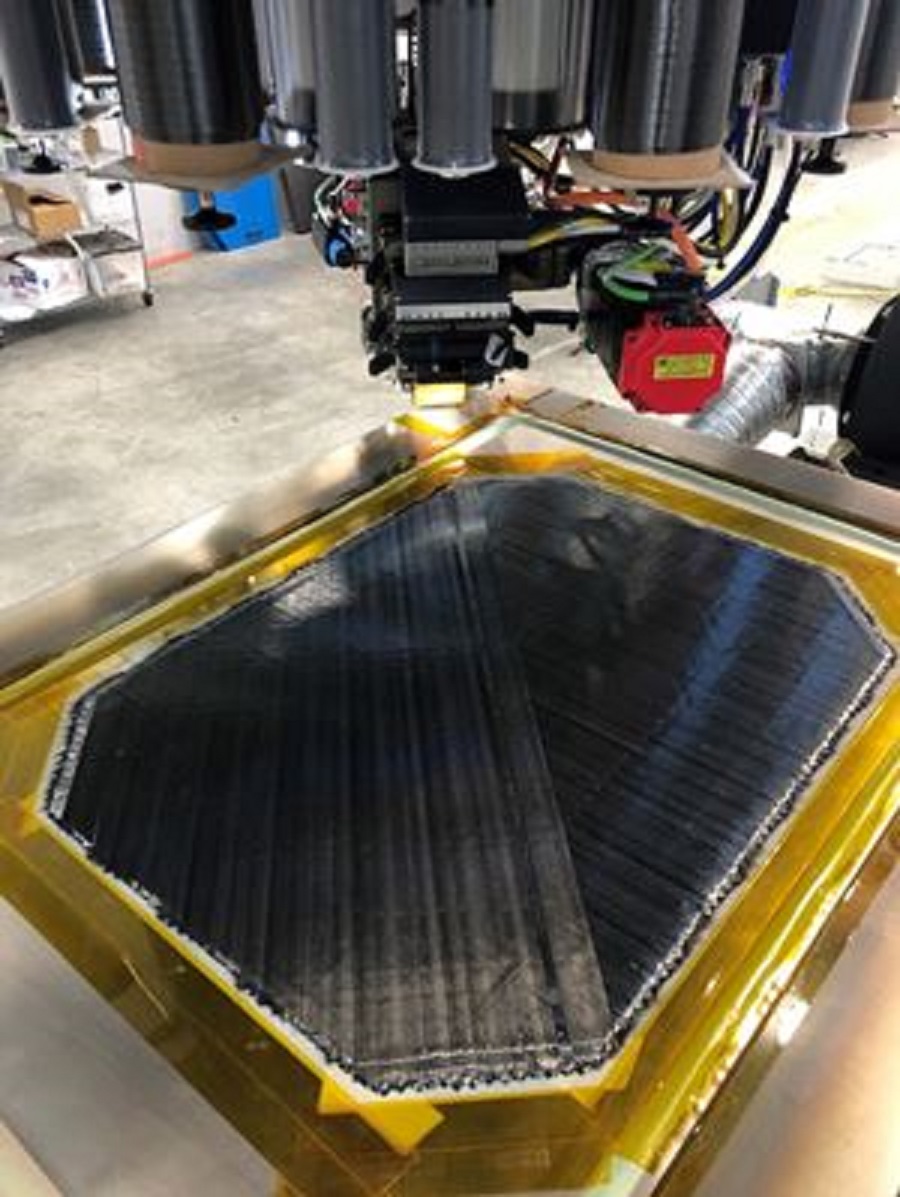

The company worked with aerospace tooling specialist Electroimpact and US engineering company Janicki Industries to improve the automated fiber placement (AFP) of Toray’s Cetex TC1225 low melt polyaryletherketone (PAEK) thermoplastic materials by using a variable-spot-size laser heating system.

According to Toray, this system uses a larger range of processing temperatures across individual tows to accommodate severe contours while enabling thermoplastic composite parts to be repairable during AFP lay-up, thereby reducing risk of wastage during part manufacture. Processing speeds of up to 4000 IPM (100 m/min) have been achieved with light or heavy tack levels to guarantee part geometry, the company said.

‘When these advancements are combined with increased AFP reliability, in-process real-time inspection and maintenance intervals, the resulting AFP 4.0 processing increases 4x-6x current productivity,’ said Michael Assadi, chief engineer at Electroimpact.

To maximise production efficiencies, the AFP layup is formed directly on to an out of autoclave heated lay-up tooling system, engineered by Janicki Industries, which is then consolidated in-situ, achieving a complete thermal process cycle in less than one hour. The tooling system is designed for scalability to accommodate parts that are too large for traditional heated press applications and can achieve faster cycle times than high temperature autoclaves.

‘The key to this technology is rapid heating and cooling rates with edge-to-edge uniformity throughout the process,’ said Todd Chace, director of research and development at Janicki. ‘Complete consolidation under vacuum bag only pressure is achieved by controlling the key stages of melt, flow, and crystallization with precise temperature control.’

This story uses material from Toray, with editorial changes made by Materials Today.