SymTerra sheet moulding compounds (SMC) incorporate bio-derived resin feedstocks and are expected to find applications in the automotive, mass transit, agricultural, heavy truck and personal watercraft industries.

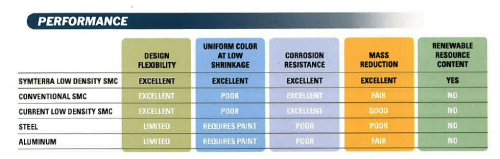

SymTerra composites have a specific gravity of 1.2 or lower. This allows for weight reductions of 30% or more versus conventional composites, and 30-50% weight reduction versus competing materials, according to TCG.

"Removing weight while maintaining full performance capabilities is key to energy efficiency, whether in a combustion-fuelled hybrid or electric vehicle or other applications where weight is a consideration," says Jeff Cash corporate director of sales and marketing, TCG.

SymTerra compounds are produced in TCG's North Kingsville, Ohio, facility which features technology that captures and eliminates VOCs released during the compounding operation.

The Composites Group, headquartered in North Kingsville, Ohio, USA, comprises Premix, Hadlock, and Quantum Composites. (See: Premix and Quantum Composites acquired by investment firms.)