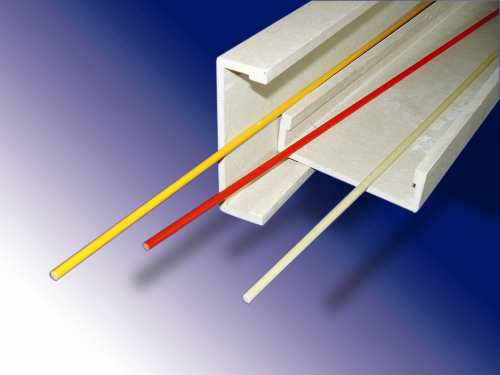

Scott Bader reports that the thermoset blend resin, based on urethane acrylate chemistry, is proving cost effective in the production of a variety of pultruded profiles for building, land transportation and other industrial applications.

The low viscosity of the resin makes it possible to achieve high filler loadings of up to 200 parts per hundred (phr) of aluminium trihydrate (ATH) fire retardant filler. This is vital in the production of pultruded profiles which have to pass stringent fire, smoke and toxicity (FST) fume test standards, as well as providing high mechanical performance in use.

Crestapol 1212, specifically developed for pultrusion by Scott Bader’s Research and Development team, is a tough, low viscosity resin, suitable for wet bath and injection applications, enabling high filler loadings (up to 2:1 filler:resin loading) and rapid wet-out of reinforcement fibres. It has a very rapid cure, with no need for post curing, enabling faster haul-off speeds in comparison to typical pultrusion-grade thermosetting resins.

Crestapol 1212 can be processed on standard pultrusion equipment without modification, using standard initiators and additives commonly used for pultrusion. Formulation advice is provided by Scott Bader’s Technical Services Department.

The resin is also compatible with standard pigments, allowing high quality colouration of components to be achieved.

Neil Gray, Business Development Manager for Scott Bader says, "Several Crestapol 1212 development projects with leading pultruders in Europe, China and South America have been completed over the last 18 months for profiles used in rail, metro and building applications. We worked closely with each pultruder to ensure that they obtained the maximum performance, cost saving and productivity benefits from their line achievable with Crestapol 1212 resin."