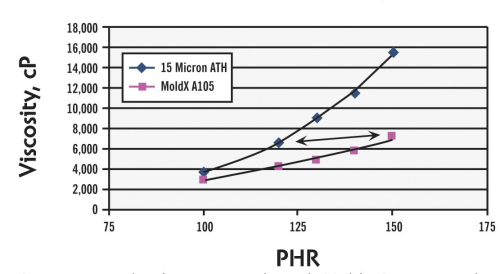

HEM says MoldX™ A105 ATH is ideal for applications such as wet-mat moulding and resin infusion where filler filtration via flow through the glass fibre mat is a concern. MoldX A105 ATH can be used in a number of applications, including pultrusion, resin infusion moulding, resin injection, wet-mat panel production, and cured-in-place pipe (CIPP). With MoldX A105 ATH it is reported to be possible to obtain higher filler loadings than with typical ATH products, resulting in increased flame retardance and smoke suppression. “The key advantage of MoldX A105 ATH is lower viscosity as compared to typical ATH products,” says Gary Rex, thermoset manager for HEM. “The low viscosity performance of MoldX A105 allows increased loading levels, from 125 to as high as 200 phr (depending on neat resin viscosity) allowing for increased FR performance. Furthermore, the displacement of polyester resin with MoldX A105 ATH can yield lower formulation costs.”As shown in the graph, an increase in loading to 150 phr with MoldX A105 gives the same formulation viscosity as a 15 micron ATH at about 150 phr.Huber Engineered Materials, a division of J.M. Huber Corporation, supplies specialty silica and silicates, alumina trihydrate, magnesium hydroxide, barium sulphate and natural calcium carbonate.