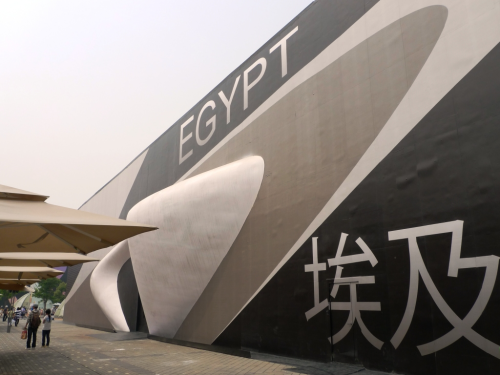

The Egypt Pavilion at the World Expo in Shanghai, China, covers 500 m2 and took three months to complete. The building was designed by architect Zaha Hadid and constructed by E-Grow, a Shanghai based company.

E-Grow made the more complex exterior and interior curved and rounded sections of the building in fire retardant glass reinforced plastic (GRP). The parts were produced by hand lay-up using Scott Bader’s Crestapol® 1212 resin and pigmented Crystic® LS30PA ISO/NPG gel-coat, supplied by Scott Bader Asia Pacific from its Shanghai distribution operation.

To ensure that the Expo building fire regulations were met E-Grow specified aluminium trihydrate (ATH) filled Crestapol 1212 urethane acrylate resin. This resin could be used throughout the construction. Crystic LS30PA pigmented spray gel-coat was selected. This UV stabilised gel-coat is designed for prolonged exterior use in building and marine applications and so will maintain its gloss and colour for the six month duration of the Expo.

The Egypt Pavilion interior is divided into two parts with a GRP arch through which visitors pass. The antiquities, films and pictures on display illustrate Egypt's history and culture.