AMI Consulting calculates that the global demand for materials for the production of wind turbine blades grew by over 20% per annum in the last five years.

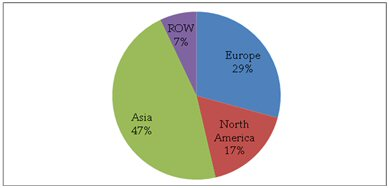

The market for wind turbine blades has been one of the fastest growing of any composite application with strong growth in Europe, North America and more recently Asia, the consultant reports, but there are uncertainties ahead and changing market dynamics. For example, in many parts of the world government support for wind energy is weakening due to budgetary constraints with consequences both for generation capacity and the distribution network, yet the long term prospects remain encouraging.

Material considerations

Increasing effort is being invested in designing blades for maximum power generation and this requires careful attention to material composition, material processing and of course overall design, AMI Consulting notes. The link between generating capacity, blade size and materials usage is discussed in the report.

To maximise return on investment, the average blade size is getting longer and heavier requiring greater quantities of raw materials. As blade length and weight increase beyond current norms increased sophistication in blade design, materials and manufacture are required.

The study investigates and quantifies demand by wind turbine blade material segmented into:

- fibre (glass and carbon);

- resin (epoxy and polyester);

- core materials (Balsa, PVC, PET and SAN); and

- adhesives (epoxy, polyurethane and vinyl ester).

It provides market data for the years 2006 and 2011 and forecasts demand for 2016.