PANEELtec, a manufacturer of large-format sandwich panels, says that it has been able to reduce weight and improve the quality of its products by using ThermHex’s thermoplastic honeycomb core.

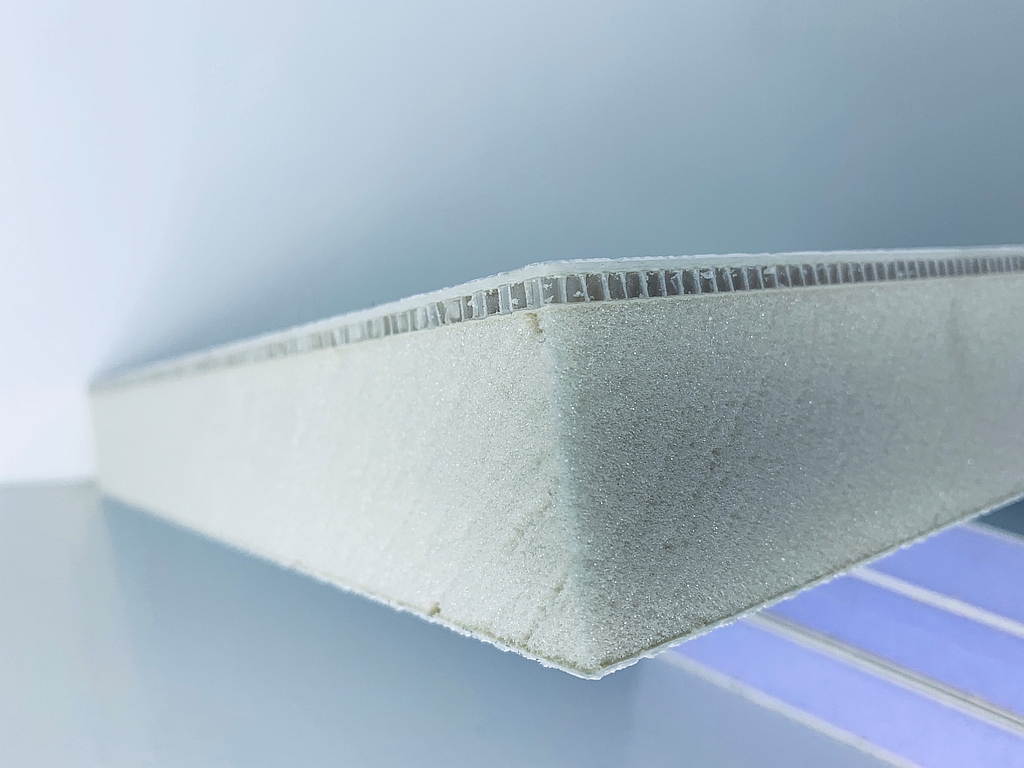

The cores are used to make panels for commercial vehicle and trailer manufacturers in Germany, Austria and Netherlands. The Duo-Core is made by adding a foam core to a 3.5 mm honeycomb core.

According to ThermHex, the panels are mechanically strong, with a 20 mm sheet thickness able to be deployed with honeycomb without problems. Previously, polyurethane (PU) foam was used, so that bubbles could form under the glass fiber reinforced face sheets.

Using a 20 mm full honeycomb panel eliminates this problem, but the panel has no insulating effect, so other cores might be required, the company explains.

‘Every gram of weight we can remove from a trailer, mobile home or boat will save energy and money,’ said Jürgen Schmidt, CEO of PANEELtec.

‘Low weight and durability are fantastic properites in panels for vehicles,’ added Dr Jochen Pflug, CEO of ThermHex Waben. ‘The addtional compression resistant honeycomb core allows to reduce the skin thickness and the foam core density.’

This story uses material from ThermHex, with editorial changes made by Materials Today.