ThermHex honeycomb cores are produced in in a fast, continuous in-line process. During this process, the core is formed, and it is also laminated.

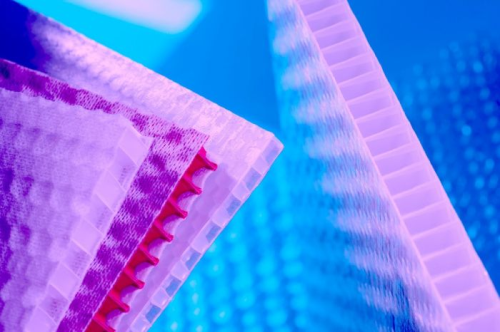

In the first step of the process polymer resin is extruded into a film, vacuum formed and then folded into a honeycomb core. In the second step thermoplastic skins can be added to form mono-material sandwich panels, but composite, wood, nonwoven, aluminium or steel skins are also possible.

The ThermHex technology allows for the production of honeycomb cores from a range of thermoplastic polymers, including PP, PE, PET, PLA, PVC, ABS, PC, PPS and PEI.

Sandwich panels using ThermHex honeycomb cores can be used for a variety of applications in the packaging, automotive, furniture, building and construction, and interior design markets.

The EconCore technology for automated continuous production of thermoplastic honeycombs (ThermHex) is protected by patents. For specific application areas and material combinations EconCore offers licences for the echnology.

Of the Chinese patent EconCore's CEO Jochen Pflug comments: “This is not only essential for the expansion of our Asian license sales to the Chinese market, but also important for our current and future licensees in Europe and America, because it further strengthens the security of investments in our technology.”