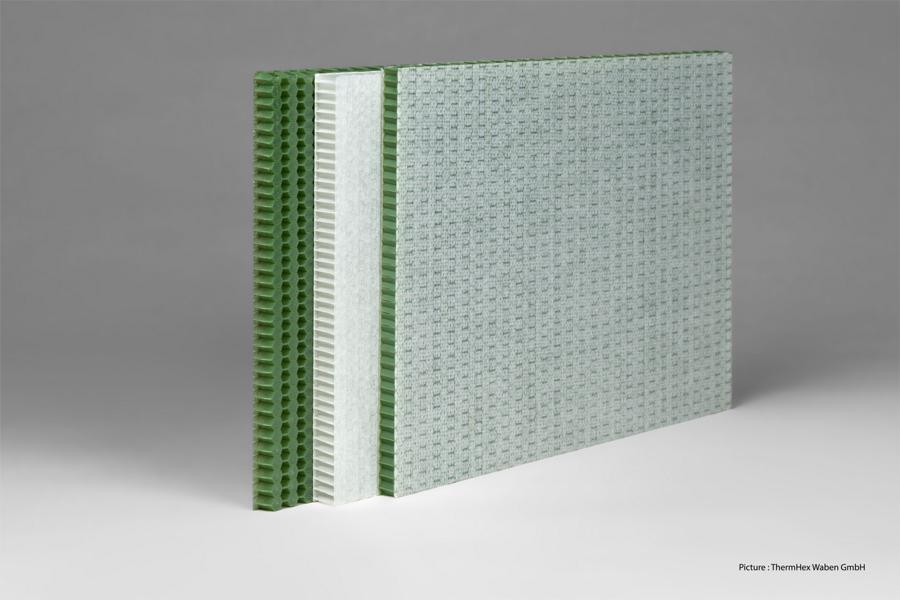

EconCore has reportedly chosen a flat die extruder made by thermoforming specialist Meaf for its trial production of recycled polyethylene terephthalate (R-PET) honeycomb sandwich panels. The honeycomb core is made of 95% recycled post-consumer PET from bottles.

‘We want to bring a smart, innovative and sustainable product to market that contributes towards the circular economy of plastics,’ said Wouter Winant, technical manager at EconCore. ‘Our R-PET core offers high stiffness and strength in compression and shear, high temperature stability and has excellent weight to cost ratio.’

The extruders can reportedly process to 1,200 kg per hour using 0.20 kWh per kg and suitable for both single and multi-layer extrusion applications using a range of materials.

This story uses material from EconCore, with editorial changes made by Materials Today. The views expressed in this article do not necessarily represent those of Elsevier.