The EU regulatory fire safety standard EN 45545, first published in March 2013, is now a critical fire and fume regulation that European OEMs designing rolling stock or any high speed railway vehicle must comply with to meet the new EC Directives covering ‘cross boarder’ interoperability for the trans-European high speed rail system.

EN 45545, which covers fire, smoke and fume toxicity (FST), is replacing all previous national fire regulations (NFF, DIN, BS,UNI), providing one European fire safety standard for the materials used in railway vehicles; HL1 is the lowest pass level, with HL3 the highest rating in the current EN standard.

Scott Bader adds that it has supplied fire retardant (FR) thermoset resins and gelcoats for composites applications in the rail industry for over 35 years. As part of the transition to this new EN 45545 standard, a number of laminate systems suitable for rolling stock and infrastructure applications were submitted for independent fire performance testing to Exova Warringtonfire laboratories in the UK; Exova is a global organisation which specialises in providing fire engineering, fire testing and fire certification services.

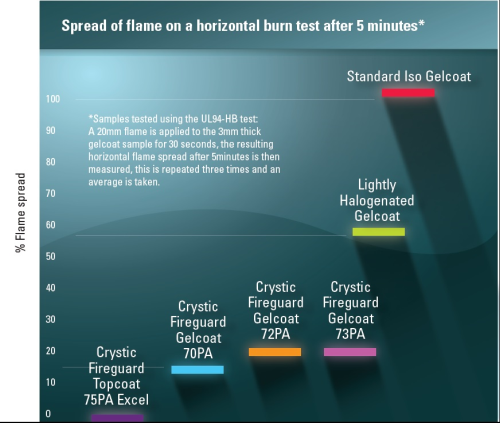

Test results from Exova Warringtonfire gave a level HL2 pass rating to the new EN 45545 standard for a test piece fabricated from a glass fibre laminate system comprising of Crystic® Fireguard 70PA gelcoat and ATH-filled Crestapol® 1212 resin, glass fibre matt reinforced. Fireguard 70PA gelcoat, combines good UV weathering properties with low flammability.

Scott Bader says that using a speciality high performance laminate system, such as an ATH filled Crestapol acrylic resin and Crystic FR Gelcoat Matched System, FRP composite parts which can meet stringent fire, smoke and toxicity (FST) standards for certain composite rail applications, can be cost effectively fabricated by a variety of processes. There are Crestapol resin grades available for closed moulding and pultrusion, along with enhanced performance ‘halogen free’ Crystic FR gelcoats with low surface spread of flame for both interior and exterior applications.

Over the last five years, Scott Bader says that iy has significantly expanded its customer base in the rail sector for vehicle and infrastructure applications using Crestapol resin in Europe, the Middle East, Africa, USA and key Asian markets, particularly in China.