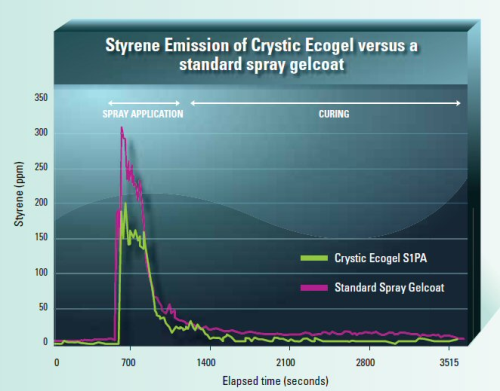

Scott Bader will showcase the ‘ultra-low styrene content’ spray gel-coat Crystic® Ecogel S1PA.

Based on independent laboratory tests, the company says that Ecogel S1PA has demonstrated its ability to help cut total styrene emissions by over 55%. It has been tested by several composite fabricators. LM Wind Power now uses Ecogel S1PA in all its wind turbine blade production plants globally.

Infusion resins

As well as low styrene gel-coats, Scott Bader will be promoting a range of infusion resins, offering EHS focused converters a full package of low VOC options for moulding high quality fibre reinforced composite parts.

Also being featured is Scott Bader’s Crestapol® range of high performance acrylic resins, including the latest addition to the range, Crestapol 1250LV. Scott Bader says that this resin can provide a high level of toughness and flexibility when reinforced with glass or carbon fibres.

Former World Rally Champion Petter Solberg's 2013 European Rallycross Championship car is fitted with lightweight body panels manufactured from carbon fibre and Crestopol 1250LV.

Crestapol 1250LV is a low viscosity urethane acrylate type acrylic resin which is suitable for infusion, resin transfer moulding (RTM), pultrusion and filament winding at room temperature.

Other grades of Crestapol will also be on display. All grades of Crestapol resin can be heavily ATH filled to meet demanding fire, smoke and toxicity (FST) performance regulations, with glass fibre and carbon fibre reinforcement grade options.