Despite comprehensive ventilation systems and strict practices on the handling of styrene, LM Wind Power wanted to look at ways of raising the health and safety standards in the company’s operations and improving the working environment for its employees.

A cross-functional group was given the task of finding an alternative gel-coat that would reduce styrene emissions in its plants by at least 50%, without compromising the quality of the product.

| LM Wind Power now uses Scott Bader’s ultra-low styrene gel-coat products in its plants globally, and has seen a major reduction (more than 50%) in styrene emissions during spray gel-coat application, without any loss of performance and using the same standard spray equipment and catalysts as with conventional gel-coats. The use of Scott Bader’s ultra-low styrene gel-coats has enabled LM Wind Power to greatly improve the environment for our workers and meet our own demanding in-house HSE standards. |

| Dan Lindvang, Senior Manager, Global Equipment Engineering, LM Wind Power |

“We applied a completely open approach,” explains LM Wind Power’s Senior Manager for Global Equipment Engineering, Dan Lindvang, who managed the project.

“Basically we were willing to try anything, even solutions that would require different processes and manufacturing methods as long as we could meet the target to reduce emissions. We wanted to be able to think completely out of the box.”

“Ideally, the gel-coat would not contain styrene at all," he adds.

"However, that would require some other solvent which would just create other and maybe unknown HSE challenges. Therefore, we focused on solutions that would cause a significant reduction of styrene emissions taking us a huge step on the way. But maybe it will be possible longer term to find completely styrene-free solutions.”

LM Wind Power pushed the development of a low styrene emission gel-coat, rigorously tested it, and implemented it in its plants worldwide in less than two years.

Scott Bader Crystic Ecogel S1PA gel-coat

LM Wind Power first scrutinised the range of low styrene content products already on the market, but then asked its key suppliers to address the problem. Scott Bader took up the challenge.

|

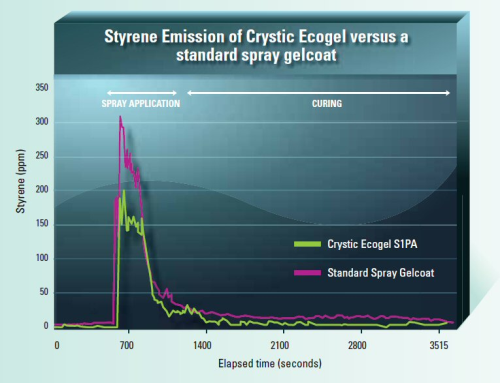

Scott Bader reports that Crystic Ecogel S1PA ultra-low-styrene-content gel-coat has good weathering resistance, good interlaminar adhesion with standard polyester and vinyl ester resins, and good gloss. The gel-coat can be spray applied in the same way as a standard gel-coat, and it cures with a standard MEKP catalyst. The workshop temperature should be above 18°C. The gel-coat film will be ready for laminating approximately 1 hour after spray application. The first layer of laminate should be applied on the same day as the gel-coat. Tests show that Crystic Ecogel S1PA has a much lower VOC emission for both the dynamic phase (airless spray) and static phase (gelation) than a standard spray gel-coat (see chart above). |

After several comprehensive lab tests and 2 million cycles on a full-scale 43.8 m blade, LM Wind Power was ready to implement Scott Bader’s ultra-low-styrene-content Crystic Ecogel S1PA gel-coat in its 12 plants worldwide. Full roll out was completed in 2012, in combination with new features on the mould that prevent the styrene from dispersing out over the sides, and the target of at least 50% reduction in styrene emissions was achieved.

LM Wind Power did not have to change any of its processes with Scott Bader’s new gel-coat as it has the same properties and curing time as the standard gel-coat.

LM Wind Power notest that the ultra-low-styrene gel-coat is more expensive than the previous one it used, but the company believes that this investment pays off.

“We have every interest in providing the best possible work environment for our employees," says LM Wind Power's VP Global Manufacturing, Richard Bevan.

"Styrene has been on the list of chemicals that we would like to eliminate if possible for quite some time. Implementing the ultra-low styrene content gel-coat has taken us a large step on the way. It illustrates how high ambitions for HSE can foster innovation and hopefully make a difference for other industry players too.”