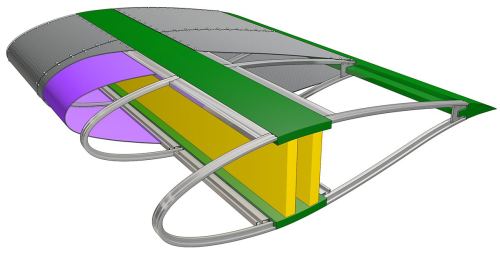

GE’s research will focus on the use of architectural fabrics, which would be wrapped around a metal spaceframe, resembling a fishbone. Fabric would be tensioned around ribs which run the length of the blade and specially designed to meet the demands of wind blade operations.

“It represents a clear path to making wind even more cost competitive with fossil fuels,” reports Wendy Lin, a GE Principal Engineer and leader on the US Department of Energy’s Advanced Research Projects Agency (ARPA-E) project.

According to GE, current blade technology (based on composite materials) does not easily allow for construction of turbines that have rotor diameters exceeding 120 m because of design, manufacturing, assembly and transportation constraints. Wider, longer wind blades are tougher to move and manoeuvre, and moulds which form the clamshell composite structure cost millions of dollars to acquire. GE’s fabric-based technology would all but eliminate these barriers, it says. The fabric will be tough, flexible, and easier to assemble and maintain.

GE also says its blade architecture will be built to achieve a 20 year life with no regular maintenance to the tension fabrics required.

With this new approach to making wind blades, components could be built and assembled on site, meaning design engineers no longer have to take into account manufacturing and transportation limitations. Taken together, these improvements will help reduce start-up costs and the cost of wind-generated electric in general.

GE explains that the use of fabrics to reduce weight and provide a cost-effective cover dates back to the World War I era, when it was used on airplanes. Over the years fabric has proved to be rugged and reliable and GE has already begun using this spaceframe/tension fabric design in the construction of wind towers for better aesthetics, cost, and protection.

It’s estimated that to achieve the goal of 20% wind power in the US, wind blades would need to grow by 50% – a figure that would be virtually impossible to realise given the size constraints imposed by current technology, says GE. Lighter fabric blades could make this goal attainable.

“Developing larger wind blades is the key to expanding wind energy into areas we wouldn’t think of today as suitable for harvesting wind power,” adds Lin. “Tapping into moderate wind speed markets, in places like the Midwest, will only help grow the industry in the years to come.”

The $5.6 million ARPA-E project will last three years.