According to AGY, the S-1 Glass fibres allow new levels of mechanical properties to be developed in the high strength areas within a composite wind turbine blade structure.

AGY developed S-1 Glass in response to the need for higher performance glass fibre reinforcement at a lower cost.

“S-1 Glass bridges the cost and performance gap between E-glass and higher performance glass such as our S-2 Glass® fibres and is, therefore, the ideal product for use in spar caps for wind turbine blades,” says Drew Walker, AGY Vice President of Sales and Marketing. “Its excellent balance of performance and cost is enabling manufacturers to optimise the design of wind blades and generate lower weight solutions, or add length to a blade with no additional weight.”

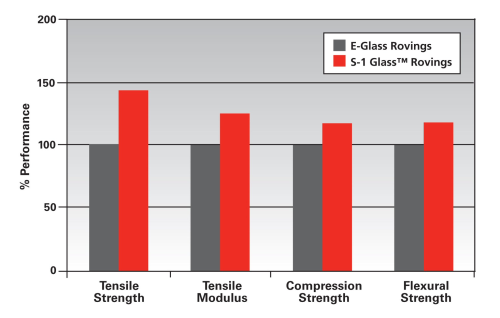

Studies have shown that, in the same resin system, S-1 Glass can have significant benefits over traditional E-glass in wind turbine blade design: a 45% increase in tensile strength; and a 25% or more increase in tensile modulus.

S-1 Glass rovings have been tested in a range of epoxy systems and AGY is working with resin companies to ensure that they will work in new resins systems as they come to the market.

“The ability to add length to a wind turbine blade allows the turbine to operate at 100% efficiency over a larger range of wind speeds," notes Walker. "This, in turn, can reduce the cost of the electricity generated. The ability to reduce weight of a blade can also have benefits in terms of reducing costs in other areas of the complete wind turbine structure.”

AGY, headquartered in Aiken, South Carolina, USA, produces glass fibre yarns and high-strength glass fibre reinforcements used in composites applications. The company has two manufacturing facilities in the USA and one in China.

Germanischer Lloyd is a classification society based in Hamburg, Germany.