In December 2011, AGY, a producer of glass fibre yarns and high-strength glass fibre reinforcements (S-1 Glass™ and S-2 Glass™) used in a variety of composites applications, announced the promotion of Drew Walker to the position of President of the company, replacing Doug Mattscheck, who resigned as CEO, President and Director.

Walker, who joined AGY in 2005 as Vice President of Sales and Marketing, will now oversee all aspects of the Aiken, South Carolina, headquartered company’s operations, strategy and business development.

| Drew has played a critical role in building the company and his promotion to President reflects the respect he has earned from our customers, partners and colleagues. His leadership and decision-making abilities, as well as his deep understanding of the industry, made him the natural choice to take AGY well into the future as the pre-eminent supplier of glass fibre yarns, reinforcements and high-performance materials.” |

| Richard Jenkins, Interim CEO, AGY |

At the same time, Rich Jenkins of Alvarez & Marsal Private Equity Performance Improvement Group LLC, a firm specialising in providing interim management and corporate advisory services, was appointed to serve as Interim CEO of the company.

A re-energised organisation

At JEC, Jenkins and Walker discussed the changes that have taken place in the company.

"In December it was decided to make a change," says Jenkins. "We have taken a look at the product portfolio, discontinued some products, and stabilised production. We have made sure what we produce is what's needed, and we have addressed the question of how we grow this business."

Walker adds that the company now has a three-year strategic plan and is currently working on several new applications (in the thermoplastics and high performance sectors). More information on these should be available within the next few months.

One new project the company is ready to announce is the signing of a long-term agreement with CTG/Taishan Fiberglass of China, under which Taishan will manufacture AGY's new S-1 HM™ glass rovings for wind turbine blade applications.

S-1 HM glass rovings

The proprietary glass formulation developed for the S-1 HM rovings was developed following feedback from wind turbine OEMs which indicated that the current need for high performance reinforcements is the highest possible tensile modulus while maintaining a balance with cost. The new glass formulation is therefore designed to maximise performance properties but at the same time allow for high volume, economic manufacture.

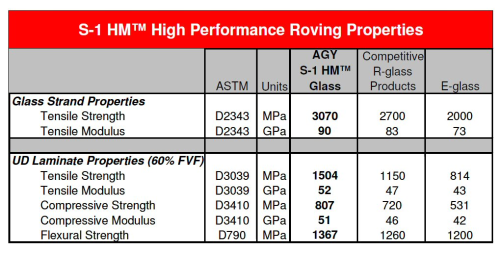

The S-1 HM rovings provide significantly higher modulus and enhanced fatigue performance compared with traditional E-glass.

According to AGY, S-1 HM rovings are the highest tensile modulus glass fibre available at 90 GPa (as measured by ASTM D2343), whereas typical E-glass products offer tensile modulus of 70-75 GPa and competitive higher performance glass fibres offer tensile modulus of 80-85 GPa.

These property improvements over typical E-glass will enable manufacturers to make larger blades, which produce more energy.

"Our rovings are specifically aimed at areas of the blade where high-performance glass will allow weight to be saved and where the extra performance of S-1 HM rovings versus a traditional E-glass will be evident," explains Walker. "For example, in the spar and spar caps, leading and trailing edge and blade root.”

S-1 HM rovings are available in a range of yields for both epoxy and polyester resin systems. The direct roving product form is tailored for standard conversion to unidirectional fabrics, prepregs and multiaxial fabrics.

Partnership with Taishan Fiberglass

CTG/Taishan Fiberglass of Shandong Province, will now produce the S-1 HM rovings under license in China. The rovings will be sold globally by both companies. AGY will focus on the wind energy markets in the US and Europe, and CTG/Taishan Fiberglass will sell to the wind energy markets in China, the rest of the Asia Pacific and African regions.

Walker explains that AGY chose to partner with Taishan after a review of several potential suppliers.

"We were looking for a partner with the infrastructure and core technology in roving materials, combined with the capability for large scale, high volume manufacture," he says.

Taishan, a subsidiary of the giant China National Materials Group Corporation Ltd (SINOMA), already manufactures a variety of products including E-glass roving, chopped strand mat, yarn, chopped strands, and fabrics. The company also has experience in the wind energy market.

“We currently supply rovings and fabrics for the large blades used in wind generation," confirms said Mr. Zhiyao Tang, Chairman and President of CTG/Taishan Fiberglass. "We will combine the new S-1 HM materials with our existing products in our sales and marketing efforts to the growing wind energy market.”

According to Walker, the new rovings took 1 year to develop but the relationship with Taishan was signed in just 4 months. He anticipates that they will be producing around 10-15 tonnes of the material in a few years time.

High voltage transmission lines

Another potential high volume application for the S-1 HM glass fibre is the new composite reinforced aluminium conductor (CRAC) being developed by US company Ampstar. As an alternative to conventional transmission cables the CRAC offers improved transmission capacity, lower line losses and less sag.

The high tensile strength S-1 HM glass fibre is combined with a high temperature resin to produce the core of the CRAC.

Walker notes that the CRAC is currently being tested in Toronto, but there are opportunities for this technology worldwide. In particular, this application offers a significant opportunity for Taishan, given China's huge and growing demand for power.

For further information see: AGY S-1 HM glass fibre used in AmpStar composite reinforced aluminium conductor.

♦