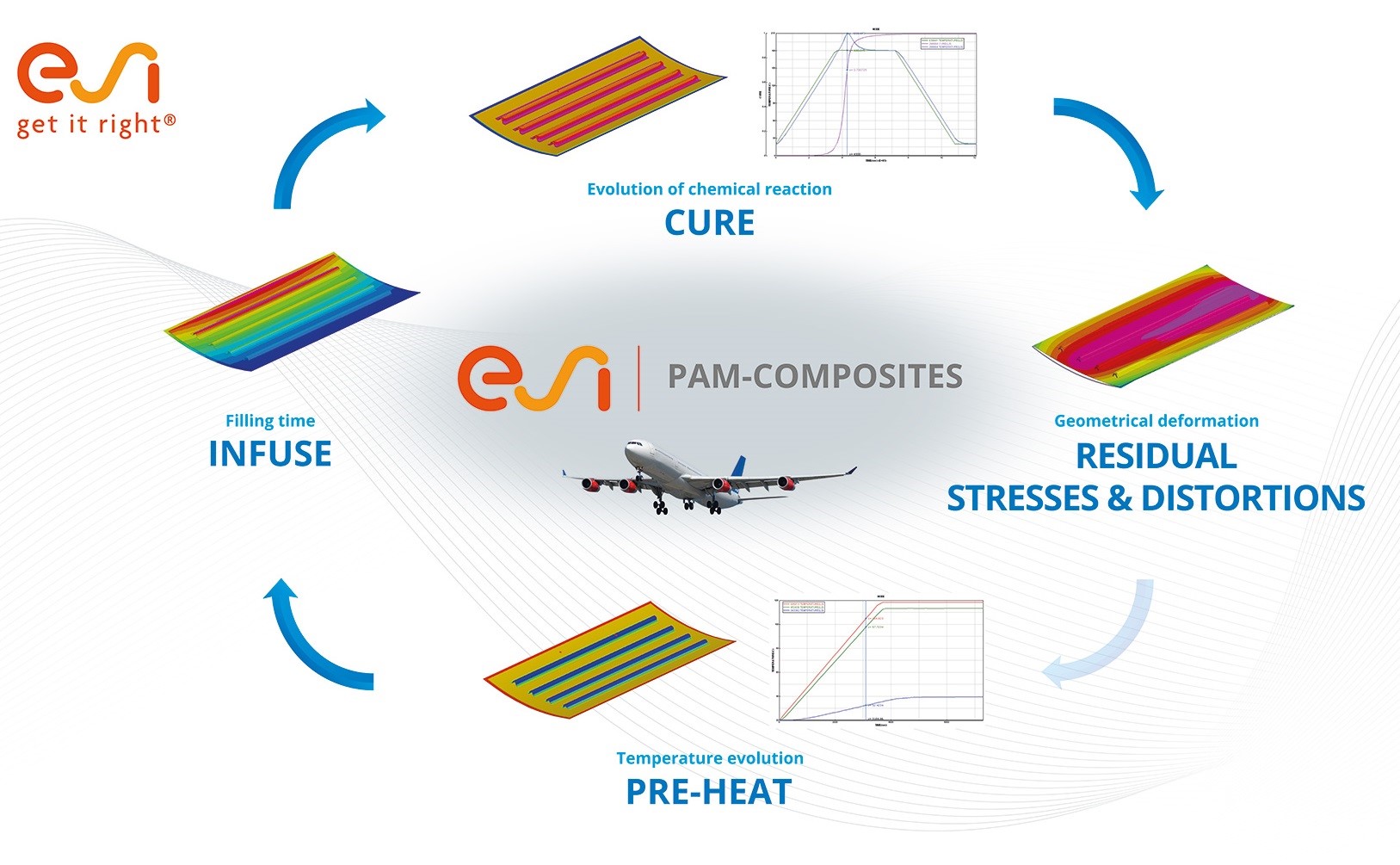

ESI Group has released PAM-COMPOSITES 2016, simulation software which allows process and design engineers to predict, analyze and correct manufacturing defects of composite structural components across the manufacturing chain.

The software features the company’s existing PAM-FORM, PAM-RTM and PAM-DISTORTION modules but now makes it possible to identify the origin of defects and manufacture composite parts with a higher degree of accuracy.

It covers a range of composites manufacturing processes including draping, thermoforming, liquid composites molding (LCM), resin transfer molding (RTM), and curing, as well as two new robot draping processes: automated fiber placement (AFP) and automated tape layering (ATL).

This story is reprinted from material from ESI, with editorial changes made by Materials Today. The views expressed in this article do not necessarily represent those of Elsevier.