AGY, Aiken, South Carolina, USA, reports that these high performance glass fibres allow new levels of mechanical properties to be developed in thermoplastics with much lower levels of glass fibre - allowing for better processing and higher impact performance.

AGY, a producer of glass fibre yarns and high-strength glass fibre reinforcements, developed S-1 Glass in response to the need for higher performance glass fibre at a lower cost.

“S-1 Glass bridges the cost and performance gap between E-glass and higher performance glass such as our S-2 Glass® fibres,” says AGY New Business Development Manager, Iain Montgomery. “Its excellent balance of performance and cost is enabling manufacturers to maximixe the benefits from high strength glass fibre rovings and allowing exciting new applications to be developed.

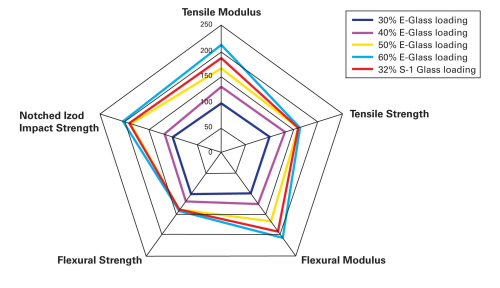

AGY says that studies have shown that a 32% of S-1 Glass fibre content in long fibre thermoplastics can deliver the same performance as a 60% of an E-glass filled product.

Reduced fibre content levels mean higher impact levels, better aesthetics and easier processing of the resins, explains Montgomery.

“Alternatively, going to high levels of fibre content with S-1 Glass would allow new applications to be found due to increases in mechanical performance from these high performance fibres,” he adds.

S-1 Glass is designed for use with a broad range of thermoplastics such as PC, PEI, PBT and PA 66. Compared to traditional E-glass, S-1 Glass has higher hydrolytic stability, a 30% improvement in tensile properties and an 18% improvement in tensile modulus.

S-1 Glass is available as a roving for use in long fibre reinforced thermoplastics and in chopped form for glass filled polymers.