Armacell, a manufacturer of PET (polyethylene terephthalate) core foams and insulation products in Germany, has introduced new products in the ArmaForm range, including ArmaForm PET AC 115 with optimised shear elongation and high compression modulus. The PET AC foams are available in a wide range of densities of 80-135 kg/m3 and are said to be well suited for wind turbine, transportation and shipbuilding applications.

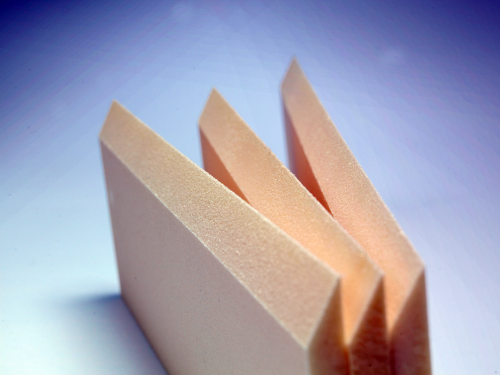

Nida-Core, a supplier of core materials based in Florida, USA, has developed NidaFusion, a closed-cell foam reinforced with 3D glass fibres which are linked to form a pyramid-shaped, fibre-truss network. The product is available in several structure types and variations for infusion and resin transfer moulding (RTM) Light processes. Among them is NidaFusion STO, a patented material that can be tailored to the needs of the application in choice of foam (polyurethane, polyester or phenolic), type and weight of reinforcements, orientation and spacing of the triangulations.

A range of environmentally friendly honeycomb core products from Nida-Core includes recycled panels made from worn carpets and nurses blouses and soy-based, foam-filled honeycomb core material for thermally efficient wall panels in refrigerated trailers or containers. The company also produces Nida-Bond core bonding compound with a 45-minute working time. The specially formulated, polyester-based bedding compound is used for hand lay-up and vacuum bagging core installation. High adhesive strength provides an excellent bond between the core and laminate, relates Nida-Core.

Acrosoma, a Belgium-based manufacturer, produces 3D stitched structural panels using patented production equipment that combines textile and composite technologies. Layers of reinforcing fibres on each side of a foam core are sewn together through the core using aramid thread. The fibre layers are then wet out with vinyl ester or other resin and pulled through a heated die to cure the panel, the company explains. PU (polyurethane), PVC (polyvinyl chloride), PET and phenolic foam can be used. Skin lay-up can be glass mats or woven high-tensile steel, aramid or carbon fibre materials or a combination. Finished panels are 2.78 m wide and 30 mm and are available in any length.

Elliott Company of Indiana, USA, manufactures Elfoam™ rigid, closed-cell polyisocyanurate foams, which are similar to but higher performing than PU foams, says the company. The product, available in a variety of densities and sizes, is widely used in composite sandwich structures due to its fire resistance, good strength-to-weight ratio and broad resin/adhesive compatibility, Elliott notes.

EconCore, a manufacturer of honeycomb cores and sandwich panels in Belgium, was awarded the 2010 Bioplastics Award by judges from Bioplastics magazine and European Plastics News for its PLA (polylactic acid) honeycomb sandwich panel. According to the manufacturer, the panel is the first 100% bio-based composite panel available. It is fabricated using the company’s patented ThermHex production technology. Once the PLA-based hexagonal honeycomb core is produced, skin layers are added in a continuous production process.

The panels are well suited for packaging, consumer goods and furniture, says EconCore, observing that they offer more disposal options and are more environmentally friendly to manufacture than traditional petroleum-based plastics.

The company also produces honeycomb cores from PP (polypropylene), PET, PC (polycarbonate), ABS (acrylonitrile butadiene styrene) and various high-heat resins. With ThermHex production technology, EconCore reports that it can produce PP honeycomb cores in 3-4 mm thickness with cell sizes as small as 3 mm.

Optimising core materials

Global composites supplier Hexcel offers the Modipur® range of polyurethane foams for wind energy and other applications. Different formulations are available for specific wind turbine applications, including the nacelle and shell, as well as for mould making. Modipur HS 480 is a CFC-free, stable, ready-formulated polyole, which reacts with isocynate US 13 to form a polyurethane foam system used for filling hollow cavities and as a core in sandwich constructions. These two-component systems can be processed on conventional or low-pressure foaming machines.

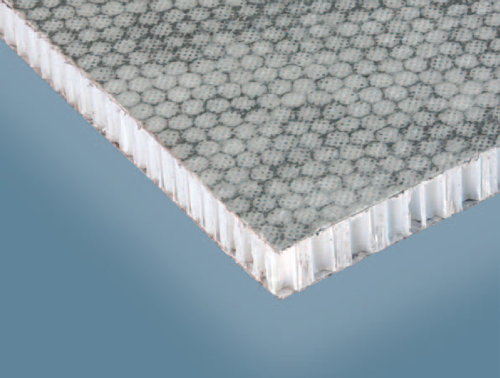

Hexcel also manufactures a range of honeycomb cores and sandwich panels, including Fibrelam® panels for aerospace, which have been in service with airlines in flooring and interior applications for three decades. Fabricated using HexWeb® honeycombs, the panels are said to provide exceptional stiffness and strength with little added weight. The company recently introduced a rapid curing prepreg epoxy resin system, HexPly® M77, and prepregs based on the system which offer good adhesive properties when bonding to honeycombs or aluminum.

The DIAB Group in Sweden has expanded the Divinycell Matrix range of foam core products for marine, wind and transportation applications with Matrix 7-7 and Matrix 11-9. Both products have received DNV certification, DIAB reports. Matrix 11-9 is said to be cost-effective and offer good mechanical properties and production efficiency. Matrix 7-7, with improved mechanical properties, is well suited for boat decks and wind turbine blades, the company notes.

DIAB has also introduced Divinycell F40 for aircraft interior applications in response to aircraft manufacturers’ demand for a cost-effective, high-quality alternative to honeycomb cores. In addition, the manufacturer has expanded its Subsea range by adding a new low-density grade to the BMTI syntactic foam range to complement the Divinycell HCP range. The new LD grade is suitable for depths of 1000-10 000 msw.

New foams in Airex range

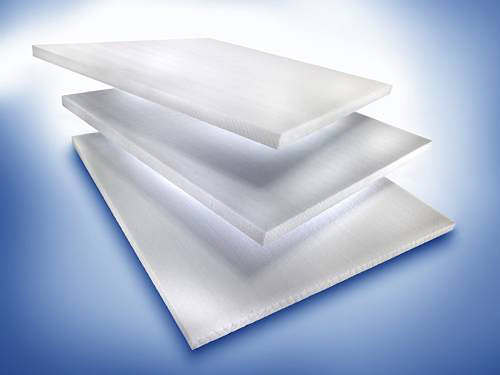

3A Composites, the supplier of AIREX® and BALTEK® core products, recently introduced AIREX T92.200 PET foam, designed to meet the needs of very highly loaded applications with its high strength, stiffness and fatigue resistance. The material is also resistant to chemicals and high temperatures, as well as being thermoformable, notes the company. Target applications include automotive floors, boat transoms and bulkheads and highly loaded sections of wind turbine blades.

Another PET foam product, AIREX T90.210, has been introduced as the successor to T90.240, featuring improved mechanical properties and fire, smoke and toxicity (FST) ratings, including shear strength, shear elongation and compression modulus. Density has been reduced by 13%, reports 3A.

The company also offers AIREX PX fibre-reinforced structural foam for sandwich composites. The closed-cell urethane foam is produced in a process that evenly distributes continuous glass fibres throughout the material, providing enhanced properties, especially in compression and shear, relates 3A. Dimensionally stable, the foam is said to be resistant to chemicals and high temperatures and exhibits low water absorption.

3A recently introduced BALTEK SBC, a new high-quality grade of end-grain balsa for sandwich core composites. The balsa wood is all sourced from 100% Forest Stewardship Council (FSC)-certified, sustainable, plantation-grown trees.

Nonwoven core material

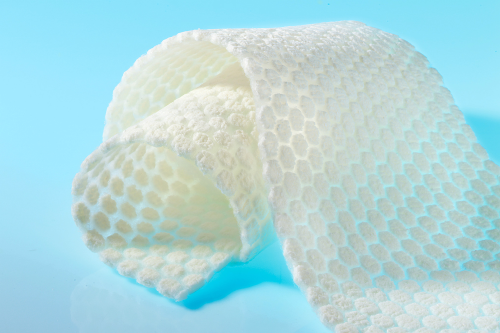

Netherlands-based Lantor BV offers the Soric® range of flexible core products for vacuum infusion. Made from polyester nonwoven material, the core features a compression-resistant cell structure. Cells are separated by channels containing synthetic microspheres, which do not absorb resin, limiting uptake. The channels promote resin flow through the core while providing excellent bonding to the outer skins, relates Lantor.

A recent introduction is FR Soric, a flexible, halogen-free, flame-retardant core to help meet FST requirements. The product range also includes Soric SF for thinner laminates, Soric XF to maximise weight reduction in structural core applications, Soric TF to meet demanding cosmetic and surface finish requirements as a print blocker in infused laminates, and Soric LRC (low resin consumption).

Soric core materials were used in the lightweight Superbus development project, a solution for future mass transit, which features sandwich composites with Soric foam in the exterior panels, floor, seats and front-end and rear-end components.

Gurit expands cores

Gurit, a leading global supplier of composite materials, has extended its structural core product range with the acquisition Spanish balsa material producer Balsaeurop and its Balsaflex® line. The Gurit range now covers balsa, PVC, PET and SAN (styrene acrylonitrile core) types, all with distinct properties and attributes. Also available from Gurit is G-PET recyclable structural thermoplastic foam.

SP-High Modulus, the marine business of Gurit, provides boat builders with pre-cut core materials and reinforcements in kit form with its B3 SmartPac. A Smartpac fibre and core package was developed for the 40 ft (12.2 m) FARR 400 production racing yacht, which is manufactured by Premier Composite Technologies of Dubai, UAE, entirely with carbon fibre/epoxy sandwich construction.

Gurit offers Corecell™ structural foam core materials in a range of products. Corecell T-Foam was developed as an alternative to PVC and balsa structural cores. Featuring low resin uptake, it shares the benefits of SAN chemistry common to all Corecell products, but provides slightly higher stiffness properties and greater styrene resistance than the more ductile Corecell A-Foam, notes Gurit. High mechanical toughness and thermal stability give Corecell T-Foam excellent fatigue characteristics, making it well suited for use with conventional prepreg materials and in some liquid infusion processes with high resin exotherms.

Corecell M-Foam structural marine foam core, marketed by SP-High Modulus, is billed as a cost-effective material comprising high shear strength, low weight/high elongation, low resin uptake for infusion processes and high temperature stability for prepreg processing. It is said to be tough, easy to machine and offers excellent uniformity through lower density variation. M-Foam is compatible with polyester, vinyl ester and epoxy resin systems.

Meeting demand for infusion

Plascore, a global manufacturer of honeycomb core products, recently announced that it has stepped up distribution of its PP Honeycomb Infusion Grade to meet the growing demand in RTM Light and infusion moulding. Made of tough, lightweight and ductile polypropylene, the honeycomb core material is well suited as a replacement for plywood, balsa and foams for production of sandwich assemblies in marine, wind energy, transportation and industrial applications, relates Plascore.

|

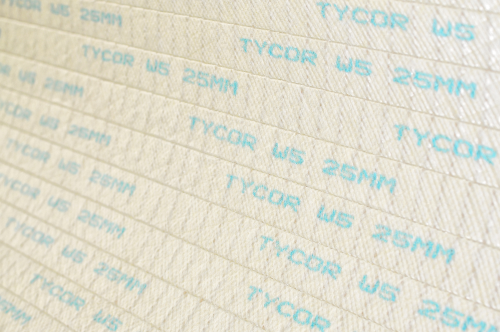

WebCore Technologies, in Miamisburg, Ohio, USA, produces its patented Tycor® W fibre-reinforced foam core materials in 5 standard grades for sandwich composites. Closed-cell, low-density foam is reinforced with glass fibres such as E-glass roving or mat to produce a core material that can be a direct replacement for balsa wood, PVC and SAN foam. The exclusive distributor of Tycore W in Europe is 3B. The material has been issued a certificate of approval by Germanischer Lloyd for use in the manufacture of wind turbine blades. The highly machineable Tycore W foam core is said to perform effectively in flat or curved shapes and with less resin absorption than other foam or balsa cores. Tycore materials are used to produce lightweight, high-strength sandwich structures for wind turbine blades, truck bodies, railcar decks, military shelters, bridge decks, cargo ship floors and runways. Especially for wind turbinesWebCore recently introduced Tycor W5 specifically for utility wind turbine blades as an alternative to balsa. The new product is designed to add higher shear properties balanced in the L and T directions, making it especially suited to the unique needs of longer, heavier blades, explains WebCore. Compared with balsa, Tycor W5 is said to offer blade manufacturers improved quality, consistent infused density, reduced resin absorption and better dimensional stability. According to WebCore, one leading wind blade manufacturer that had been using thick balsa in the shear webs of the blades replaced the wood core with Tycore foam in 2008, after noticing a strain on balsa supplies. The result was a weight savings of 325 lbs (147.4 kg) per blade as well as a cost savings. Tycor W is still being used in the company’s blade production. Large sheet sizes reduce the number of core segments needed to load blade moulds for fewer core joints, faster fabrication and enhanced core fit at adjoining segments, relates WebCore. Another Webcore product line, Tycor G has been selected by the US Airforce to develop rapid-assembly, energy-efficient composite shelters. The core material uses advanced three-dimensional fibre architecture and cost-effective automated manufacturing processes to produce lightweight, high-strength, robust sandwich structures well suited to this application, notes the company. |

Developed specifically for RTM Light, closed bag or infusion processes, the product features a composite surfacing bonded to a high-impact copolymer isotropic honeycomb core. The sealed cell design promotes resin flow at the bond line with minimal penetration into the core for structures with excellent strength-to-weight ratios, core shear strength and compression properties.

Evonik Industries, Germany, manufactures ROHACELL® high-performance structural foam core for lightweight sandwich composites. ROHACELL was used extensively in the production of a two-seat electric car called the Wind Explorer that crossed Australia in 17 days last January. The car, which weighs just 200 kg (440.9 lbs), features a wind turbine for recharging the batteries and a 6 m (19.7 ft) high mast with parasail-type kites to supplement electrical power. The bodywork of the car consists mainly of carbon fibre fabric skins cored with Rohacell foam.

Manufactured from polymethacrylimide (PMI) foam, ROHACELL has recently been gaining ground in automotive applications, relates Evonik, noting that the product has been used successfully in aircraft, marine and transportation applications. CFC-free, ROHACELL foam’s high rigidity improves the inherent rigidity of the sandwich composite components. It also offers high thermal resistance, making it well-suited for thermoforming with short cycle times.

A concept vehicle from Mazda, based on the MX-5 sports car, features a bonded, two-piece monocoque structure fabricated from polyurethane composite sandwich materials. Baypreg® F, from Bayer MaterialScience was used to produce various composite components for the MX-0 concept. The composite structure weighs 100 lbs (45 kg), compared with 665 lbs (302 kg) for the production MX5. The two-component Baypreg F PU system was used to produce the fibre reinforced sandwich panels for the vehicle.

Balsa-cored tank trailer

A composite cargo tank trailer earned the Best of Show ACE Award for Composites Excellence for Corrosion Companies Inc of Washougal, Washington, USA, at the American Composites Manufacturers Association (ACMA) Composites 2011 show in Fort Lauderdale, Florida. The filament wound tank trailer, designed to transport corrosive liquids, featured a BALTEK SB.100 balsa core and a DuraShield carbon fibre continuity system as the inner liner designed to monitor the integrity of the liner.

The ACE Process Innovation Award was presented to Acell USA and Italpresse USA, both of Punta Gorda, Florida, for the patented Acell Monolithic Composite process. The unique sheet moulding compound (SMC) sandwich moulding process uses Acell foam as the core layer. The sandwich is pressed in a heated mould in a 120 ton Italpresse hydraulic press in a 4-6 minute cycle, causing the SMC material to liquefy and penetrate the open cell foam to form a strong mechanical bond. Surface finishes can be applied to the mould before laying in the SMC. Italpresse, a leader in pressing equipment, developed a dedicated press for the process to be used by Acell licensees. ♦

|

The ASTM International Committee D30 on Composite Materials is developing a new standard for sandwich structures. Practice for Damage Resistance Testing of Sandwich Constructions, WK30231, will be the first industry standard to cover this topic, relates the organisation. Interested parties are invited to join in the development by contacting ASTM International. Other published standards for composites include the D6264/D6264M Test Method for Measuring the Damage Resistance of a Fibre-Reinforced Polymer-Matrix Composite to a Concentrated Quasi-Static Indentation Force, and the D7136/D7136M Test Method for Measuring the Damage Resistance of a Fibre-Reinforced Polymer Matrix Composite to a Drop-Weight Impact Event. ASTM states that WK30231 will provide instructions for modifying the test methods in those two standards to determine damage resistance properties for sandwich constructions. The properties are needed to demonstrate that a sandwich structure is sufficiently durable and exhibits no damage or limited damage under specific damage-producing events in service. |

This article was published in the July/August 2011 issue of Reinforced Plastics magazine. To appy to receive your copy of the magazine please complete the subscription form. (The digital edition of Reinforced Plastics magazine is distributed free of charge to readers who meet our qualifying criteria.)