General Lasertronics Corporation began investigating laser composite surface preparation in 2006, the objective being to improve repeatability of adhesive bonding processes for aerospace composites. Lasertronics developed specific laser parameters for surface preparation, including wavelength, fluence, irradiance, and pulse duration, which enhanced the adhesion of coatings to composites. Adhesives applied to laser-processed bismaleimide (BMI) carbon fibre reinforced polymer (CFRP) samples demonstrated fracture toughness values much more repeatable than did adhesives applied to conventionally prepared surfaces. Double cantilever beam (DCB) tests confirmed that laser preparation also produces highly repeatable bond fracture toughness (G1C) values with superior fracture mode behaviour. This project was a rigorous follow-up to those preliminary observations. Its primary objective was to quantify the degree to which laser surface preparation improves repeatability of adhesive bond properties in an industry-standard aircraft composite, IM7/5250-4 laminates joined with AF-191 epoxy, cured at 350°F (177°C). The adhesive bond properties achieved with laser-prepared samples were compared to bonds produced with conventional manual-abrasive-with-solvent-wipe processes. The test matrix included surface energy measurements, DCB bond fracture toughness tests, and electron microscopic analysis of test samples.

Technical background

Reliable adhesive bonding of organic matrix composites requires effective, repeatable surface preparation. Current surface preparation methods include sacrificial peel-ply layers, grit blasting, and manually-applied abrasives, typically followed by solvent wiping. These high-labour content processes inherently deliver variable outcomes. They can damage the outermost reinforcing fibres in the composite substrate, and they all produce significant waste streams. Finally, abrasive processes are not consistently effective in removing significant contaminants, such as mould release agents and hydrocarbons, from the faying surfaces of adhesive joints. This presence of contaminants degrades bond repeatability.

The primary objective of this project was to quantify the degree to which laser surface preparation can improve repeatability of adhesive bond properties in bonded joints between high-performance BMI composite (IM7/5250–4) laminates joined with 350°F-cure AF-191 epoxy, while maintaining or improving baseline bond toughness. Using DCB tests, bonds made with laser-prepared test samples were compared to otherwise identical samples and bonds prepared with an aircraft manufacturer's baseline manual abrasive surface preparation process.

A secondary objective was to demonstrate an automated laser surface preparation process for composites that could be scaled up for real-world airframe manufacturing applications.

|

The sessile-drop test (from the Latin sessilis, ‘pertaining to sitting’) is an accepted method for measuring surface energy of a surface. The sessile drop test infers surface energy value by measuring the angle between the surface and the edge of the bead that forms when a droplet of the chosen probe liquid is placed on the surface to be investigated. This is called the contact angle. Contact angle indicates the surface energy balance between polar and dispersive forces in the liquid as it forms droplets after being applied to the test surface. A low contact angle, characteristic of a large footprint and low profile, indicates high surface energy, better adhesive wetting characteristics, and high receptivity to coatings, including adhesives. A near-vertical contact angle, characteristic of a small footprint and high profile, indicates low surface energy and poor receptivity to coatings. Each material has inherent characteristic degrees of receptivity to coatings. Surfaces that readily accept coatings are easier to paint or bond together with adhesives than surfaces that do not. Polymer surfaces typically do not readily accept coatings, which makes composites difficult to paint or bond with adhesives. A surface that is highly receptive to coatings will allow a liquid drop placed on it to spread out and occupy a large footprint. As a result of this spreading out, the droplet will exhibit a low profile (low contact angle) with the surface. Raindrops on a car that has not been waxed exhibit this behaviour; they are flat, and barely recognisable as separate droplets. A surface that generates this large-footprint, low-profile droplet formation is referred to as a high-energy surface. Conversely, a surface that is not receptive to coatings will characteristically prevent the same droplet from spreading out, causing it instead to occupy a small footprint and exhibit a higher profile (higher contact angle) with the surface. Picture raindrops beading on a waxed car hood; each drop is quite distinct and erect. This is referred to as a low-energy surface condition. For applying paints, sealants, or adhesives to a surface, a high-energy surface condition is obviously desirable. Some materials, including many composites, have characteristic surface energy so low that coatings adhere poorly. The sessile drop test was used to measure surface energy in this project. |

Laser process physics

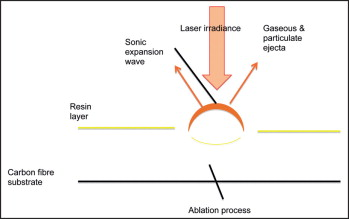

The ablative effects of laser radiation on the surface of a composite material are fundamentally different from the mechanical effects of peel ply removal, grit blasting or sanding. The two primary parameters that drive ablation at the material surface are:

- Laser irradiance, which is the energy rate per unit area (Joules/sec/cm2), and

- Laser fluence, which is the total energy per unit area (Joules/cm2). Irradiance multiplied by exposure time equals fluence.

The plasma dynamics, thermochemistry, and thermal radiation events at the surface ‘photoablate’ (vaporise) contaminants, adsorbate films, and an extremely thin (several millionths of a metre) layer of the composite's resin matrix phase. Extremely short laser pulse duration (shorter than 200 nanoseconds) effectively controls any heat conduction into the substrate. Lasertronics’ systems deliver high-power, short-duration pulses of laser energy, with real-time closed-loop controls that accurately regulate the spatial distribution of laser energy delivered to the surface.

Directed laser energy acts much as a ‘photonic peel ply’, and eliminates the need for chemicals, abrasives, or blast media for surface preparation. The laser energy converts most of the photoablated mass into a gaseous-phase effluent. The residual particulate waste stream is typically less than 50% of the mass of the material removed. Particulate waste is efficiently captured by a vacuum waste collection system and sequestered in a paper HEPA filter. This is the entire waste stream. Thus, laser photoablation inherently minimises the environmental, health, and safety problems associated with composite surface preparation.

In order to produce a controlled, repeatable laser ablation process that does not damage the composite substrate, the target material must fully absorb the laser energy in a shallow surface layer, to prevent penetration deep into the substrate. Understanding the optical absorption characteristics of the matrix phase material is a key consideration in designing a controlled, repeatable laser process for composite materials. Lasertronics discovered that laser pulses with high irradiance and short duration are readily absorbed by the matrix-phase material in various types of composites. This absorption characteristic protects the reinforcing fibres and makes this laser process ideal for composite surface preparation applications.

Any laser energy that may penetrate into the composite matrix phase is partially absorbed in the composite material. Experience with different types of composites confirms the ability of carbon fibres to absorb moderate energy levels without adverse effects. Heat conduction in composites is highly anisotropic - typically five to ten times greater in the longitudinal (axial) direction than in the through-thickness direction. This characteristic allows the material to function as an efficient heat sink to dissipate any energy absorbed.

Scanning electron microscopy (SEM) of laser-processed samples confirms that the laser process photoablates composite substrates to a depth of 3-5 microns (μm). This ‘photonic peel-ply’ process removes an extremely thin layer of matrix material, while leaving the carbon or glass reinforcing fibres unaffected. However, the laser has unique advantages over peel ply:

- The laser covers the entire surface uniformly.

- The laser does not produce broken fibres or panel curvature.

- The laser is a robotic process that essentially eliminates touch labour.

- The laser produces almost zero waste material.

- The laser chemically functionalises the surface.

- The laser can be configured for automated, real-time acquisition of parametric data from the manufacturing process; this enables accurate analysis of digital process control metrics to facilitate quality protocols such as Six-Sigma, SPC, for example.

These advantages enable the laser process to deliver superior repeatability in the bonding process and in related outcomes. This assures a highly-controlled manufacturing process with consistent outcomes.

Detailed SEM analysis of laser-processed samples confirms that the laser does not ablate or damage carbon fibres while photoablating the surface of the matrix-phase resin material. The shallow extinction depth of the laser enables highly repeatable laser effects with tight six-sigma process metrics. The laser is a non-contact, directed-energy process, so it is inherently compatible with conventional automation strategies. Laser ablation increases the repeatability of the process outcome while substantially reducing touch labour and nearly eliminating waste.

For example, a robotic laser system is currently in use at the US Navy's Fleet Readiness Center-East to remove paint coatings from main rotor blades of CH-53E helicopters. The Navy expects to extend the process to include H-60 and V-22 rotor blades as well.

Surface energy testing

Surface energy is a recognised measure of a material's receptivity to coatings and adhesives. For this project, screening tests using a Brighton Probe instrument to measure sessile-drop contact angle evaluated the effects of different laser processing conditions on the surface energy of the composite material used in this project. (See Sessile-drop contact angle testing sidebar)

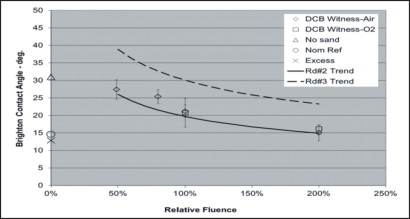

For this project, three rounds of surface energy screening tests including 111 samples were performed to assess the impact of laser surface preparation. An important result was the monotonic correlation between laser fluence (total energy per unit area) and contact angle. Higher laser fluence levels directly correlated with lower contact angles and better wetting characteristics. These data show that laser surface preparation measurably improves the surface energy values of the composite material. Higher surface energy values typically correlate with improved coating adhesion.

Samples prepared with the aircraft manufacturer's baseline manual abrasive process and a derivative (over-sanded) process were tested for comparison against laser-prepared samples to quantify surface energies and variability in process outcomes.

Results of the screening tests guided selection of the DCB test matrix. For all laser samples, one baseline level of pulse irradiance was used, but laser fluence (exposure time) was varied to allow correlating the outcome of the DCB results to fluence levels.

|

Adhesively bonded joints between composites typically exhibit three primary fracture modes during DCB testing:

Test specimens often exhibit a mixture of these three failure modes during DCB tests. In general, composite bonding procedures seek to eliminate adhesive failure modes, because this mode indicates adhesive bonds with low strength and low failure toughness. During DCB testing, cohesive and interlaminar failure modes are strongly preferred to adhesive-mode failures at the faying surfaces of the bond joint. The consensus among technical specialists is that bond failure mode exhibited during DCB testing provides critical information about the overall integrity and fracture toughness of the bond joint. |

Further information

General Lasertronics Corporation; rcargill@lasertronics.com

Lasertronics designs and manufactures specialised laser systems for coating removal and surface preparation. Lasertronics’ systems incorporate unique closed-loop, real-time electronic control technology that provides a precise, repeatable distribution of laser energy on the target surface, while protecting the substrate from any changes in material properties.

See Part 2 of Laser surface preparation of composite materials