Composites can be moulded into aesthetically appealing, multi-curved deck structures, while their low weight both reduces vessel mass overall so that they are more easily driven, and enhances stability by lowering centres of gravity.

The superstructure on the graceful Marco Polo, a 146 ft Transocean Explorer class motor superyacht built by Hong Kong-based Cheoy Lee Shipyard to designs by Ron Holland Design, comprises two reinforced plastic enclosed decks and an open deck on top. Hand-laminated panels plus some that are infused are stiffened both by selective inclusion of infused carbon and by resin-infused beams.

High Modulus carried out the structural engineering for the Marco Polo. A large part of the composite structural engineering company’s involvement was the determination of the laminate specification for the lower and upper enclosed decks and the fly bridge. Use of glass reinforced plastic (GRP) in chopped strand mat and multiaxial woven roving form with structural foam core enabled targets for weight, structural integrity and cost to be met. Panels were stiffened both by selective inclusion of infused carbon and by resin-infused beams. Carbon is also incorporated into the radar arch and mast, which are integrated into the upper open deck level. Builder Cheoy Lee was an early pioneer in the use of fibreglass construction in Asia and has had a 16-year collaboration with High Modulus.

As it happens, High Modulus has been involved in a number of contemporary superyacht projects. The company engineered a complete carbon structure for ERMIS 2, a 120 ft motor superyacht which, with its deliberately unostentatious appearance, is a veritable ‘wolf in sheep’s clothing’. Meeting the owner’s stated need for a craft that is outstanding for its speed rather than its visual aspect, ERMIS 2, designed by Humphreys Yacht Design, can sprint at 60 kts, thanks to an ultra-light structure along with triple-engine and waterjet propulsion. Despite her size, the vessel displaces just 98 tonnes and draws less than 5 ft.

High Modulus’ design brief for ERMIS 2 was simple, to develop a structure to withstand twice the load at half the weight of a conventional fast superyacht. McMullen and Wing in New Zealand was tasked with building the yacht. On the basis of studies using finite element analysis (FEA) and other tools, it was decided to build a fully post-cured, female-moulded, vacuum-infused carbon fibre reinforced epoxy/foam structure. Only this approach offered the prospect of providing the required combination of strength, stiffness and low weight. Female moulding limits weight by avoiding much filling and fairing of a large structure after demoulding, while vacuum infusion secures an accurate distribution of resin whilst avoiding surplus resin and weight. Infusion can also produce a high quality laminate with minimal void content.

To meet stringent weight targets, cored construction was maintained even into the bottom hull structure. A need for especially high toughness in sections where the slamming loads would be greatest was met with a combination of high-elongation Airex linear foam core coupled with carbon and Kevlar-reinforced epoxy skins.

The resulting shell structure was not only considerably stiffer than equivalent solid carbon fibre composite laminate would have been; it was also substantially lighter. High Modulus used impact tests to demonstrate that appropriately engineered linear cored sandwich structure could survive repeated high impacts. In-house mechanical testing of strip laminate samples from various parts of the vessel was carried out to verify bending strength and stiffness values as well as to prove the quality of core bonding and jointing achieved by the vacuum infusion method. In every case, says the company, the laminate performed significantly better than would be expected of equivalent laminate specimens produced by wet lay-up. The final structure of the vessel is said to weigh approximately half what an equivalent wet lay-up glass/epoxy/foam core structure would weigh.

Another carbonfibre yacht engineered by the company is the 128 ft lift-keel sailing sloop Project Sunshine from the board of Tripp Design. The Green Marine-built structure is of carbon/epoxy prepreg skins over foam core. Special attention has been paid to the area of structure around the keel case where loads generated by the 35-tonne lifting keel have to be distributed into the hull and internal structure.

High Modulus has also been involved in the structural engineering design of the largest all-composite motor yacht ever – a 186 ft craft that will gross over 500 tons. Christensen Shipyards will build its Custom 186 at a new purpose-designed facility in Tennessee, USA. Christensen, which has been building large fibreglass motor yachts for over 20 years, already produces 160 ft Custom 60 superyachts. High Modulus is developing the structural specifications for the new series as part of an international team responsible for the final product, the first of which is due to launch in 2011. Vessels are both custom and series built, customers having a wide choice over configuration and layouts but based on proven series-produced hulls.

In detailing the laminate for one of the latest creations of iconic superyacht builder Wally Yachts, the 130 ft Wally 130 sloop, High Modulus engineers specified both high-strength and intermediate-modulus carbon fibre for the prepreg carbon and Nomex honeycomb core sandwich structure. In form the yacht follows the current design school favouring a sharp vertical bow graduating to a broad, flat stern with a low bulb keel on a slim foil. Structural engineers, involved in the design process from the start, worked closely with naval architects, designers, stylists and builders to achieve the elegant minimalist look for which Wally is famous. The final solution is strong, stiff, light and blends seamlessly with the interior and exterior styling. The bulwarks, for example, are sufficiently robust in themselves not to need the support frames normally required, so that the visual line remains unbroken.

Advanced composites, including both carbon and glass fibre laminates, are also the material basis for the 118 ft WallyPower 118 fast motor yacht. Three gas turbines totalling 16 800 hp and waterjets thrust the low-weight composite structure to a top speed of about 60 kts. Wally has put its characteristic stamp on the hull and superstructure, which are angular, entirely uncluttered and have flat surfaces that are more reminiscent of a stealth fighter aircraft than a yacht.

From super to mega

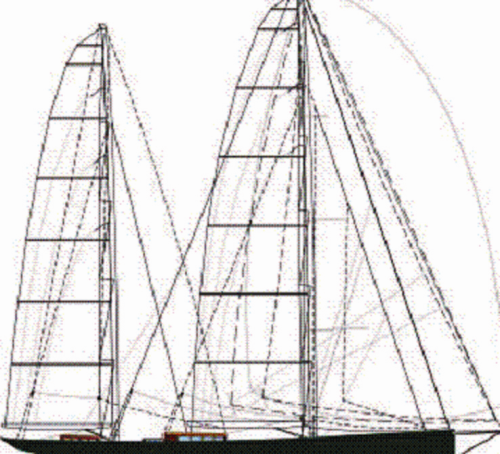

A yacht that is uncompromisingly modern behind an exterior that harks back to the more graceful days of traditional sail is the latest from Gerard Dijkstra & Partners, a studio noted for its daring designs, and in build at Baltic Yachts in Finland. This 221 ft long vessel is rigged as a ketch (two masts) so that she can comply with an air draught limit of 205 ft needed for passing under bridges on the Panama Canal. For that reason she is dubbed the ‘Panamax ketch’.

While wood could have been chosen for authenticity, it was considered advantageous to base the structure on composites to achieve the expected fair and graceful lines, and to meet a requirement for good performance. Low weight was desirable and the carbon-skinned foam-cored hull and deck structure together weigh a creditable 45 tonnes. All spars look suitably traditional but are of carbon composite.

Above the waterline and when rigged, this megayacht will be visually reminiscent of the fast sailing cutters of a century and more ago. The hull, too, will be visually in keeping with the period – at least above the waterline. Below the waterline, a large ballast weight in a hydro-dynamic bulb will be located some 29 ft beneath the hull on a high-tensile steel foil/strut when sailing, though the keel can be raised to reduce draught when motoring or when in soundings.

Dijkstra has previously been associated with other design envelope-extending sail yachts including the phenomenal Maltese Falcon, the 1200-tonne 283 ft long 21st century square-rigger owned by venture capitalist Tom Perkins. While this, the world’s largest private sailing craft, has a steel hull, her innovative rotating-mast rig has been made possible by composites. Although the Dynarig concept was developed by a German hydraulics engineer in the 1960s, the materials then available made it unviable. Maltese Falcon has three free-standing masts, each 185 ft high and weighing 13 tons, and each able to rotate in a socket at its base.

Each composite mast carries six curved carbonfibre yards, and these carry five individual sails per mast. Because the masts are free standing and without rigging to hold them up – a feat of technology enabled by advanced composites – they can be rotated to suit the wind direction. Southampton, UK-based company Insensys designed the carbonfibre rig, incorporating within it fibre-optic sensors for monitoring stresses and strains exerted on the rig when sailing. These constitute essential feedback for the automated system that provides push-button control of the rig, including electric motor operated setting and furling of the sails.

A high rig is a similarly striking feature of what has for some time been the world’s largest sloop (single-masted sailing yacht), the 247 ft long, 750 tonne Mirabella V. In this case, though, the entire primary structure of the vessel is reinforced plastic. VT Shipbuilders constructed the hull and superstructure in glass and aramid reinforced vinyl ester skins sandwiching Herex PVC foam core. Use of sandwich up to 2.6 inch thick in some places ensures high panel stiffness, and carbon/epoxy composite is included at points of high tensile load. Kevlar fabric is buried centrally within the hull lay-up to resist major abrasion, leaving glass outer plies to absorb minor scrapes and damage. The hull was moulded as a single entity in a female mould, with cure taking place in an enclosed heated environment.

VT subsidiary Halmatic produced the incredible single 286 ft carbon fibre composite mast in two halves that were subsequently bonded together. The Ron Holland-designed Mirabella V can sail guests at 20 kts, a speed once associated with power-only mega-yachts.

Superyacht demand has exploded with the growth in the world supply of supremely wealthy individuals. Creating vessels to suit this demanding clientele poses structural and performance demands that verge on the extreme. Composites, with their unique ability to be tailored specifically for a given application, have shown that they can meet the challenge.