Fraunhofer scientists and partners have developed a wood-polymer composite (WPC) material for furniture that is resistant to humidity and has low flammability.

This makes the material especially suitable for bathroom and outdoor furniture, where natural wood can become discolored or moldy.

As part of the EU-sponsored LIMOWOOD project, researchers at the Fraunhofer Institute for Wood Research collaborated with industrial partners in Belgium, Spain, France and Germany to develop materials that can be formed into the moisture-resistant WPC boards. Even after being immersed in boiling water for five hours, the material emerged intact, whereas conventional wood particle board was completely destroyed by this test.

Catching fire

Moreover, by choosing appropriate additives, the researchers were also able to improve the fire-retardant properties of their WPC boards. The formula was initially developed on a laboratory scale, using commercially available, halogen-free fire retardants which were added to the wood-polymer mixture during the melt phase. The first step involved determining the limiting oxygen index of the item under test: this parameter defines the behavior of plastics or wood-filled plastic compounds when exposed to flames. It represents the minimum concentration of oxygen at which the material will continue to burn after catching fire and the higher this value, the lower the material’s flammability.

Schirp and his colleagues obtained the best results with a combination of fire retardants such as red phosphorus and expanded graphite. The limiting oxygen index of WPC boards treated in this way extends up to 38%, provided the wood particles they contained were also flame-proofed. By comparison, the limiting oxygen index of a standard wood particle board is 27%, and that of an untreated WPC board is 19%. Even in a single-flame source test, in which a Bunsen burner is held against the test sample, the treated WPC boards demonstrated a high fire resistance. Even after 300 seconds’ exposure, the boards didn’t catch fire. By contrast, the reference samples – of a standard wood particle board and an untreated WPC board – caught fire and continued to burn.

The only limiting factor on applications of WPC is its inability to support high static loads, the researchers report. However, it was possible to increase its bending strength to a level that exceeds that of conventional particle board by utilizing a judicious mix of component materials.

Sustainable material

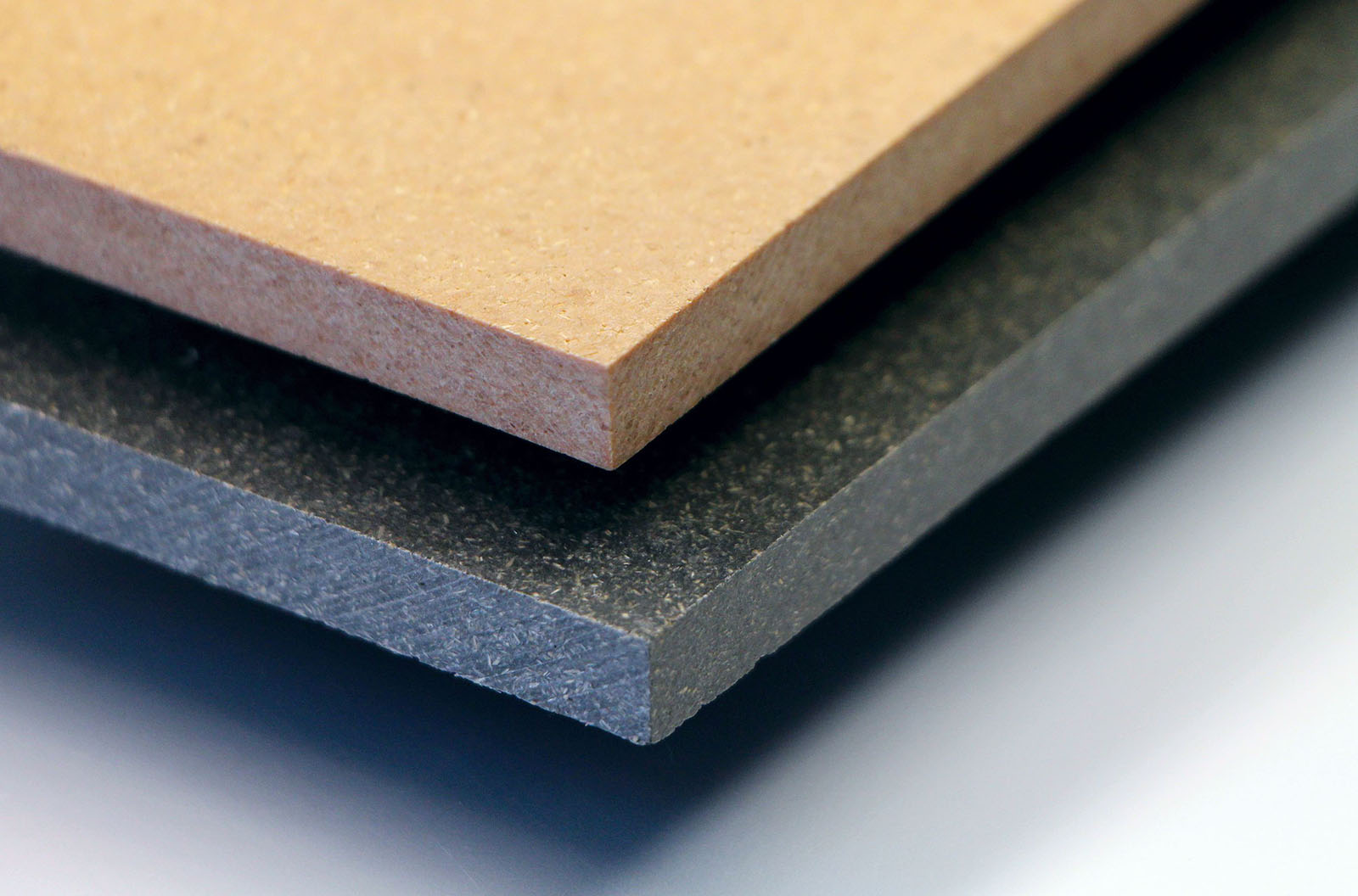

These boards are reportedly composed of around 60% wood particles and 40% thermoplastic material, generally polypropylene or polyethylene. Both wood and plastic components can be sourced from recycling streams and are themselves recycleable. The wood component in WPC boards can also be replaced by other lignocellulose products derived from the fibrous part of plants such as hemp or cotton, or the husks of rice grains and sunflower seeds.

According to the researchers, the pressed WPC boards produced by the researchers are formaldehyde-free. ‘The controversial question of formaldehyde emissions due to the binder used in conventional pressed wood products is therefore not an issue in this case,’ said research scientist Dr. Arne Schirp.

While the most commonly used WPC processes are injection molding and extrusion, in which the various components – wood fibers, thermoplastic materials, and additives – are melted under high pressure at a high temperature and formed in a continuous mold, Dr.Schirp’s team placed its focus on press technology, because it is the best way to produce boards for use in furniture construction. ‘The resulting boards have the same visual appeal as all-wood products and can be glued or screwed together to produce attractive furniture. They’re suitable for all decorative, non-loadbearing elements.’

This story is reprinted from material from the Fraunhofer Institute for Wood Research, with editorial changes made by Materials Today. The views expressed in this article do not necessarily represent those of Elsevier.