BASF says that its new polyethersulfone Ultrason E material makes it easier to make sandwich structures for airplane interiors.

The same material can reportedly be processed into different components of the sandwich structure in a single tool, helping reduce cycle times and manufacturing costs.

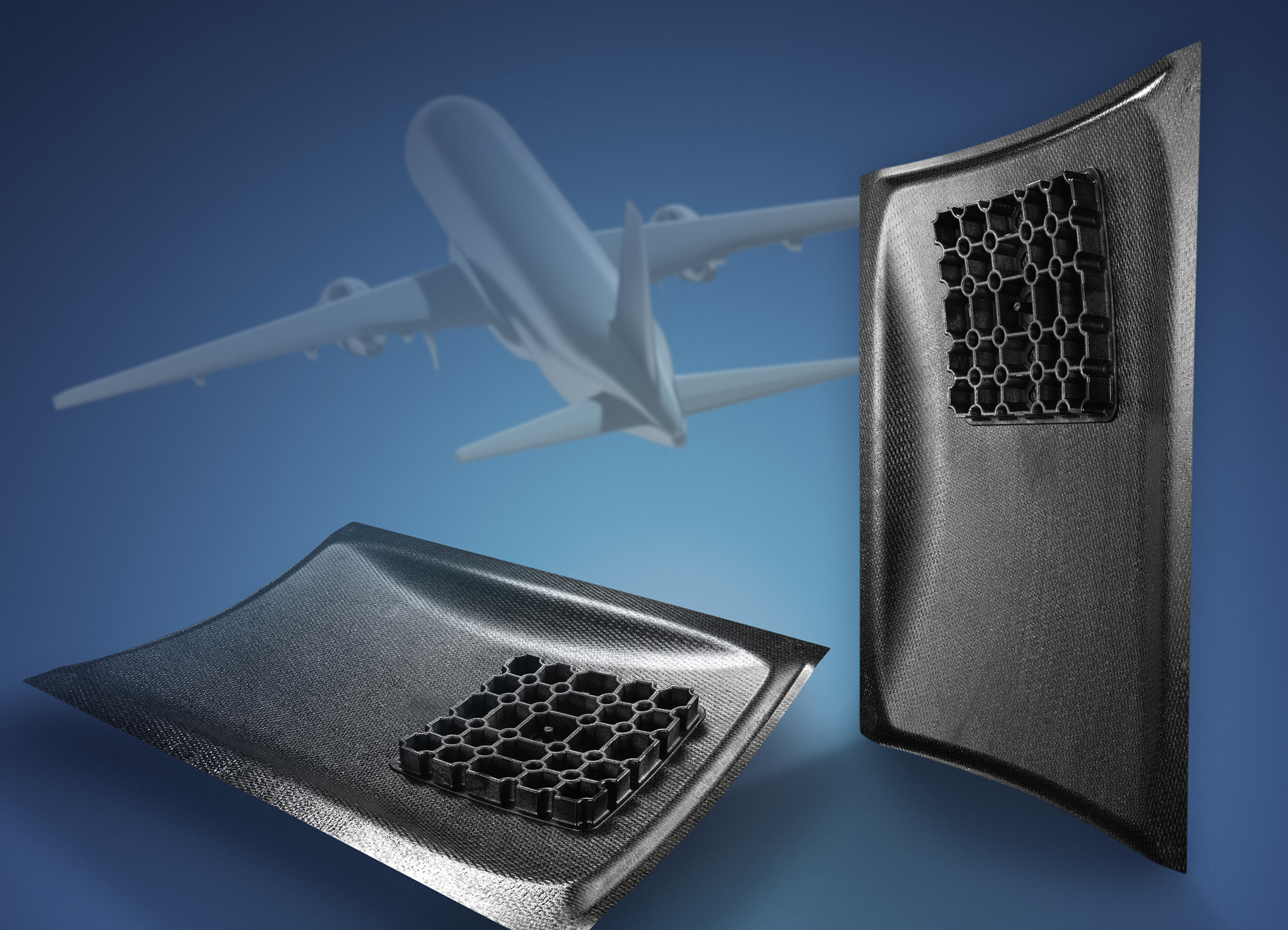

The sandwich consists of a foam core and carbon fiber laminates made of Ultrason E, and if required, the thermoformed foam core with cover layers can then be overmolded with carbon-fiber reinforced Ultrason E 2010 C6 to incorporate reinforcements, structures or additional functional elements into the sandwich. The combination of 30% carbon fibers with the amorphous high-temperature plastic can improve mechanical properties for the light foam sandwich over a temperature range of -100 to +200°C.

The material, has a limiting oxygen index of 38 (according to ASTM D 2863) and meets the requirements for commercial aircraft with regard to combustibility and heat release without the addition of flame retardants.

This story is reprinted from material from BASF, with editorial changes made by Materials Today. The views expressed in this article do not necessarily represent those of Elsevier.