Solvay says that it has added its 10% carbon fiber filled KetaSpire polyetheretherketone (PEEK) and neat Radel polyphenylsulfone (PPSU) materials for simulation in additive manufacturing (AM) simulation software.

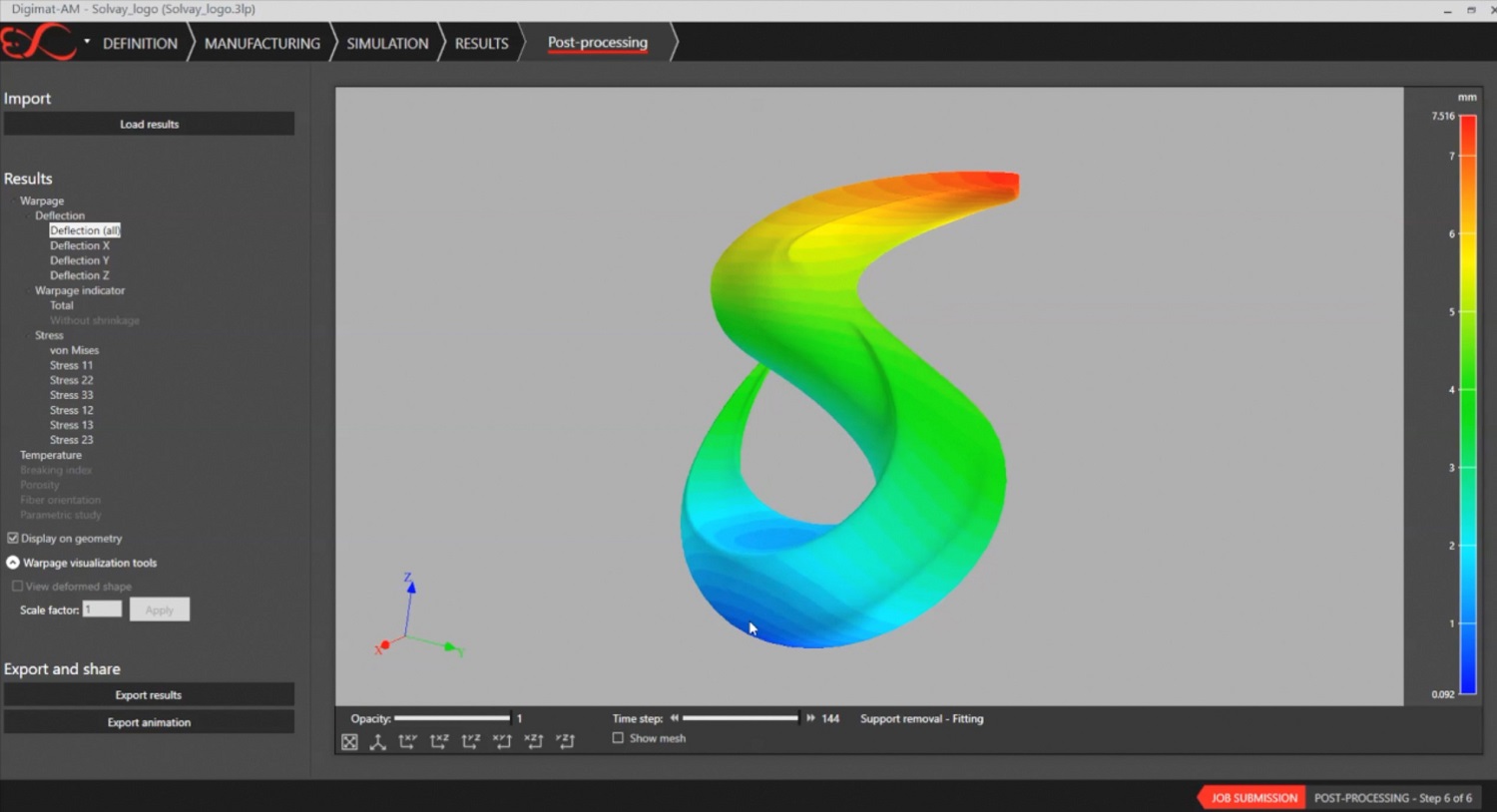

Digimat Additive Manufacturing (AM) software, made by e-Xstream engineering can also simulate the company’s KetaSpire PEEK AM filament.

‘Our growing range of AM filaments underscores Solvay’s determination to establish itself as an industry leader in this rapidly evolving market,’ said Christophe Schramm, additive manufacturing business manager at Solvay. ’Digimat-AM allows customers to simulate the printing process and successfully predict the thermomechanical behaviour of 3D-printed designs.’

The Digimat AM Advanced Solver software offers predictive modelling data for Solvay’s 3D printing materials over a range of critical characteristics, including detailed warpage and residual stress.

This story uses material from Solvay,with editorial changes made by Materials Today. The views expressed in this article do not necessarily represent those of Elsevier.