Solvay says that its KetaSpire PEEK filament for 3D printingwill be the first polyetheretherketone polymer included in recently devloped simulation software.

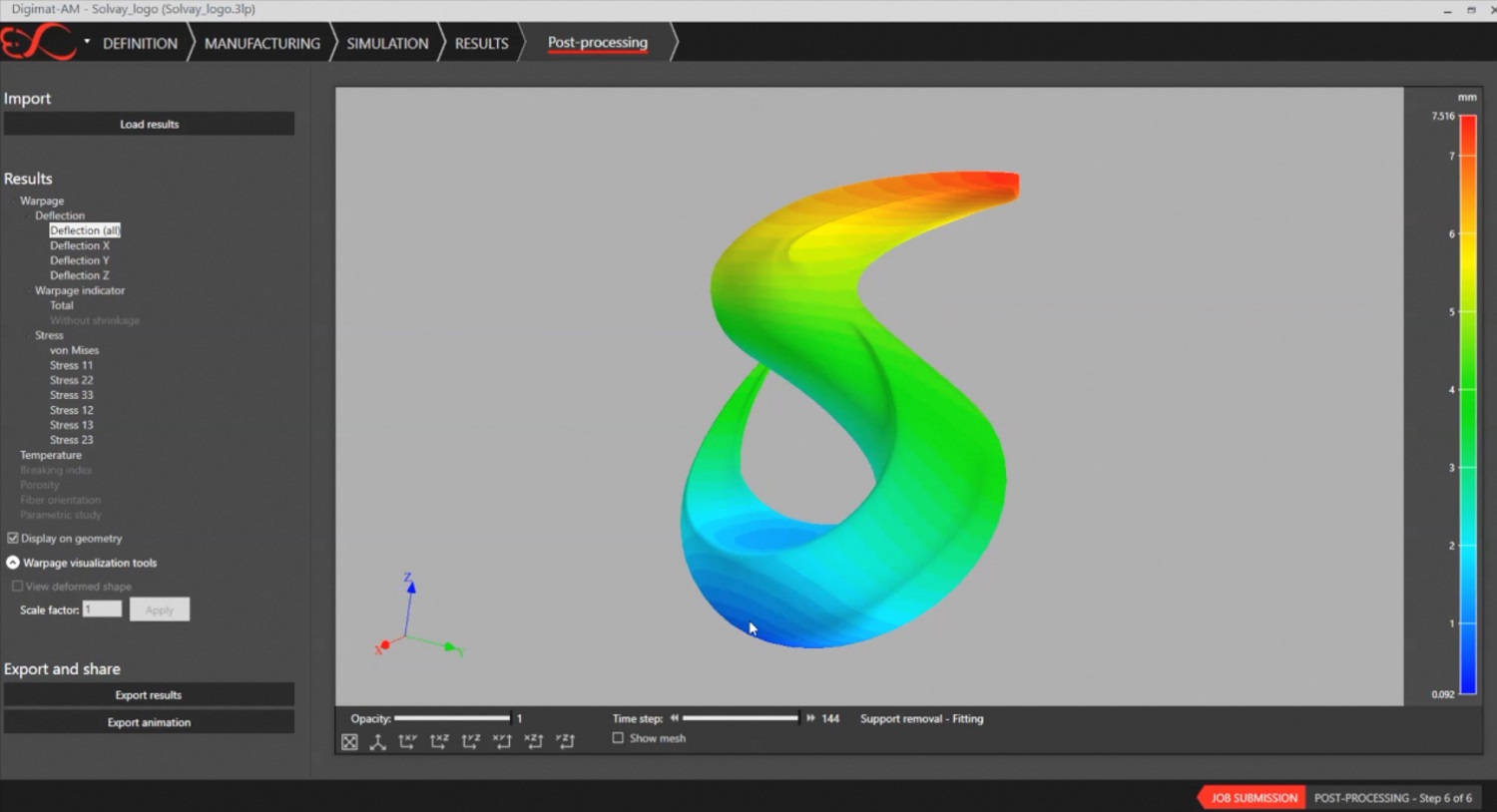

Digimat for Additive Manufacturing, developed by e-Xstream could enable designers and engineers to accurately predict warpage and the residual stresses of 3D-printed KetaSpire PEEK parts as a function of additive manufacturing processes, such as fused filament fabrication (FFF).

‘KetaSpire PEEK’s inclusion in Digimat represents Solvay’s latest step toward becoming the industry’s leading resource for successfully applying advanced polymers in 3D printing processes,’ said Christophe Schramm, business manager for additive manufacturing (AM) at Solvay.

This story uses material from Solvay, with editorial changes made by Materials Today. The views expressed in this article do not necessarily represent those of Elsevier.