Engineered foam specialist Armacell and engineering company Swiss CMT have joined forces to develop what they say is the first particle foam made from 100% recycled polyethylene terephthalate (PET).

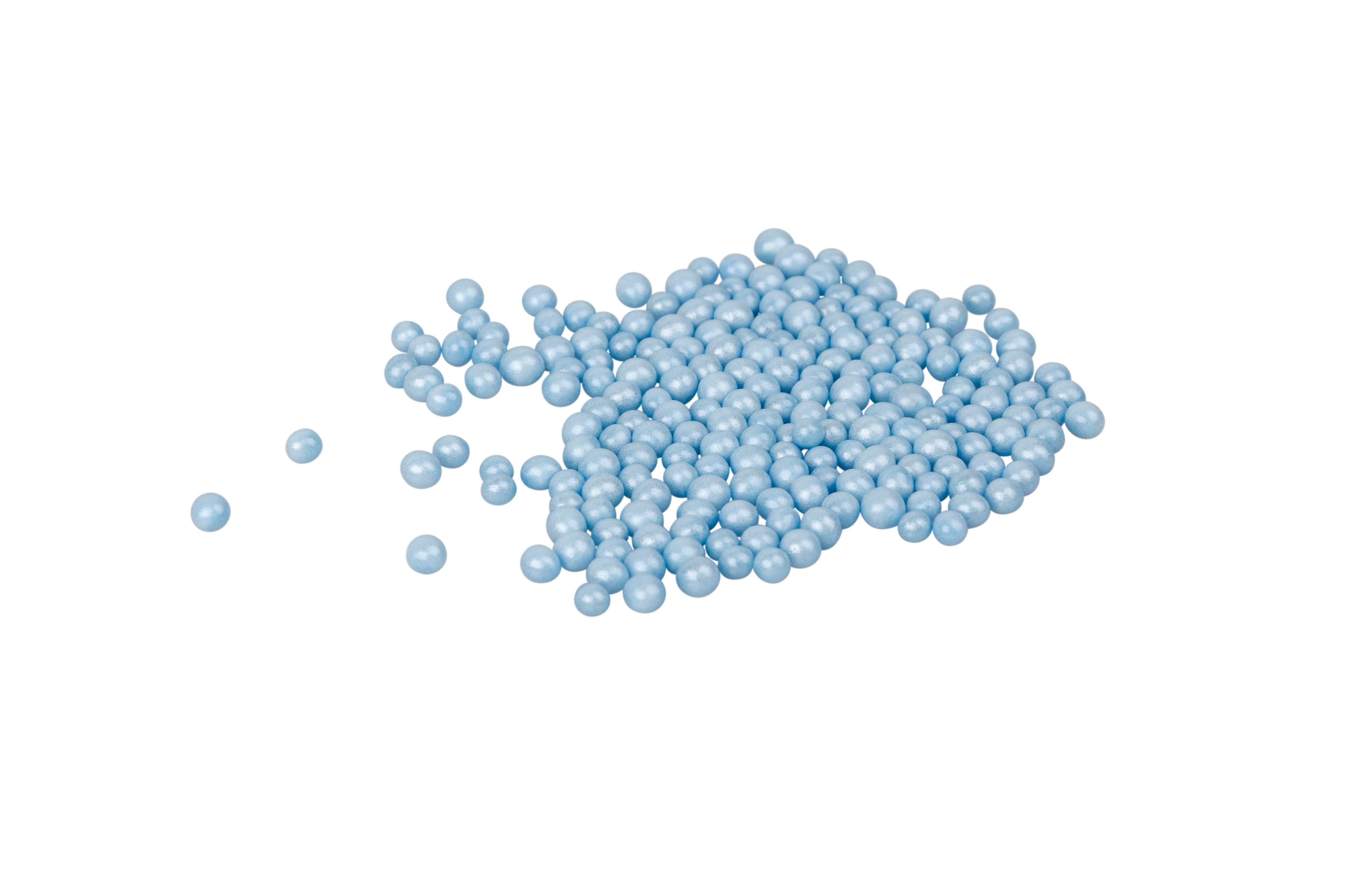

As part of a joint venture, the two companies plan to focus on pre-coating the ArmaShape foam with a hybrid resin system when it is in the form of loose beads. This new way to apply a thermally curable coating helps improve the molding process and provides permanent bonding and improved adhesion to multiple materials such as glass and carbon fiber, according to Armacell.

‘The core competency of Armacell is the extrusion of expandable PET with properties tailored for various industrial applications,’ said Dr Justyna Dolega, global innovation manager at Armacell. ‘The development partnership with Swiss CMT provides us with additional product capabilities, providing easier and faster molding into three-dimensional parts.’

‘This is our solution for cost-effective serial production of structural composite parts with the highest level of design flexibility and sustainable responsibility,’ added Bart Janssen, Armacell’s vice president of engineered foams.

This story uses material from Armacell, with editorial changes made by Materials Today. The views expressed in this article do not necessarily represent those of Elsevier.