BASF says that it has installed a Sumitomo Demag injection molding machine to produce test specimens made of high temperature fiber reinforced thermoplastics.

The IntElect 1000 kN automated injection molding machine is located at the company’s injection molding and extrusion pilot plant in Ludwigshafen, Germany. BASF says that the machine can deliver repeatable results on over 4,000 test settings a year.

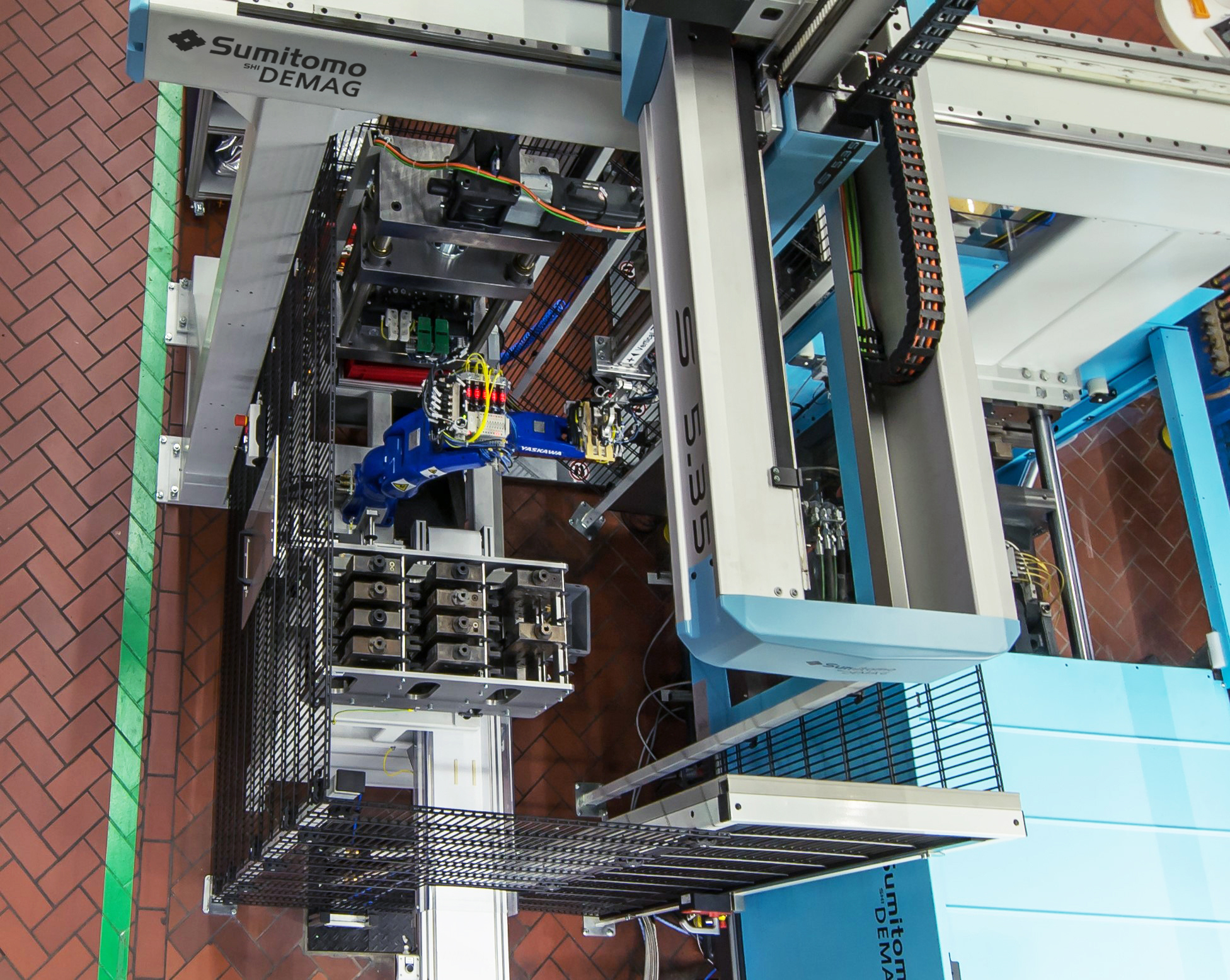

The IntElect 1000 kN incorporates a linear SDR 5-35S robot that automates the selection and placement of one of 12 interchangeable mold inserts from a magazine located within the cell. After the part is molded, the same robot fitted with a multifunctional gripper extracts the test specimen from the mold and passes it to a six-axis articulated-arm Yaskawa GP8 robot for cut of the specimens from the gate using a servo spindle drive punching machine.

The installation also includes an existing thermal temperature control unit and a new digital manufacturing execution system (MES) to map each test sequence., BASF said.

According to Markus Hausmann, automation engineer at Sumitomo, thermoplastic melt temperatures can reach up to 400°C with mold temperatures hitting up to 180°C. ’In order to lower the temperature to 80°C and depressurize the insert to guarantee that the SDR robot could remove the mold insert safely, our machine control has to talk and interact seamlessly with BASF’s MES,’ added Hausmann.

BASF’s MES informs the cell when the current produced sample setting is about to end, lining up the next mold application, and after the injection process stops, cooling of the mold insert is directed by the integrated temperature control unit interface. The change of the mold inserts is synchronised to the cell control via output and input signals with transmission of the new mold data record via the robot interface. After the change of the mold insert, the temperature control units are heated up again. Automatic operation resumes and a new mold data record is initiated as soon as the target temperature is reached.

According to the company, because it tests a wide range of materials, removal by punch was a pre-requisite, as it does not change the material properties and eliminates dust particles. As well as this, many of the materials BASF works with having high fiber glass content which can cause warpage. The machine’s multifunctional gripper helps ensure all sample geometries are placed with precision onto the punch plate, the company said.

The control program of the cell also had to be adapted to different materials, sample geometries, temperatures and processing parameters.

This story uses material from BASF, with editorial changes made by Materials Today. The views expressed in this article do not necessarily represent those of Elsevier.