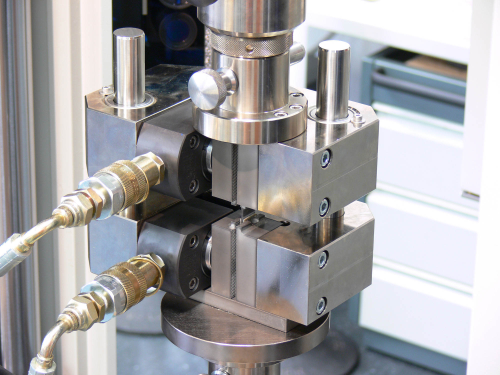

According to Zwick, the fixture delivered good results in tests carried out by a major European aircraft manufacturer in 2010. The HCCF was developed and patented by IMA Materialforschung und Anwendungstechnik GmbH in Dresden, Germany, and it is produced and marketed by Zwick.

The compression test is one of the most important tests performed on carbon fibre composite materials, explains Zwick. However, it can be a challenging test to perform accurately because introducing the load to the specimen is problematic and flexure and stress peaks can easily lead to erroneous test results.

The new HCCF from Zwick is said to eliminate these problems and give better control during tests. It is reported to enable shorter testing times and avoid errors. It is very flexible, allowing different shapes of specimens to be tested.

Compliant with the Airbus AITM 1-0008 industry standard, the HCCF can also be used for notch compression tests (OHC, FHC) to AITM 1-0008. Versions that can be used at temperatures of between -60 °C and +150 °C are also available.

Testing software

Zwick has also updated its testXpert II software to include an expanded range of standard test programmes for the composites industry. The company can now supply more than 40 standard test programmes for composites, including all established types of test (such as tensile, compression, interlaminar shear strength, flexure, shear etc.) and all standards (such as ISO, EN, ASTM, Airbus AITM, Boeing BSS).