The additional functionality in the systems used by Hexcel and the increase in the number of different specimen types and shapes, means that now the latest systems can undertake tensile and flexural tests inside a temperature chamber, operating in excess of 300ºC for tensile tests and between 23ºC to 300ºC on flexure tests.

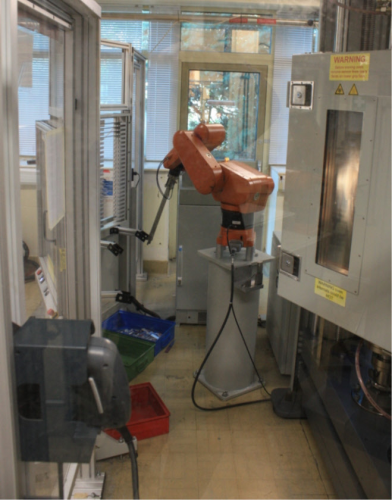

This is achieved by using robots to handle the specimens between the user magazine and the testing machines. When testing above and below ambient temperature there are many challenges for testing laboratories. The test throughput is influenced heavily by the time taken for the temperature chamber, test fixtures, and specimen to reach the desired test temperature. All of this is handled automatically by Zwick’s latest roboTest® system which controls the temperature based on the pre-set test specification.

The robot system inserts the specimens through a specially designed door in the temperature chamber and into the hydraulically controlled tensile grips or on to the flexure fixture. One of the robot's main strengths is its ability to test a set of specimens with very little temperature variation between specimens. The test is then carried out automatically by the robot system, which takes over the process including the application of a digital extensometer, and allows operators to do other tasks.

When carrying out flexure tests the span of the rig is motorised and is set by the software according to the test specification, ensuring that specimens are always tested correctly. At the same time, the testing system records the specimen temperature and logs it on the test report and in the data file together with all the mechanical test results.

“Testing using robotics removes many sources of error from the test. At the same time it allows the operator more time to concentrate on specimen preparation,” says John Rennick, Hexcel’s Laboratory Engineer. “After production the specimens are measured by an automatic measuring unit, and this helps us to guarantee high reproducibility of test results from the very beginning. Once the cross-sectional area is transmitted from the measuring unit, the optimum gripping pressure for the hydraulic tensile grips is set. This makes sure that the specimen is gripped correctly and avoids excessive forces which could cause specimen damage leading to premature failure of the specimen.”

Hexcel says that one of the main advantages of the automatic specimen measuring unit is the consistency of the specimen measurements which reduces errors in subsequent steps in the testing process. The specimen measuring unit also aligns the specimen so that each one can be inserted into the testing machine in precisely the right position and orientation, which would otherwise be difficult to achieve manually all of the time.